Information injection-pump assembly

ZEXEL

101491-9801

1014919801

NISSAN-DIESEL

167000T010

167000t010

Rating:

Service parts 101491-9801 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-0T001

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

ZEXEL

101491-9801

1014919801

NISSAN-DIESEL

167000T010

167000t010

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.15

3.25

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.4

Pump speed

r/min

950

950

950

Average injection quantity

mm3/st.

70.4

68.8

72

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

11

9.2

12.8

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.4)

Pump speed

r/min

950

950

950

Average injection quantity

mm3/st.

70.4

69.4

71.4

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.3

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

75.4

71.4

79.4

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

101

85

117

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1000--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

950

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

(1000)

Advance angle

deg.

1

0.5

1.5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1275+50

Advance angle

deg.

1

0.5

1.5

Timer adjustment_05

Pump speed

r/min

1580

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

Test data Ex:

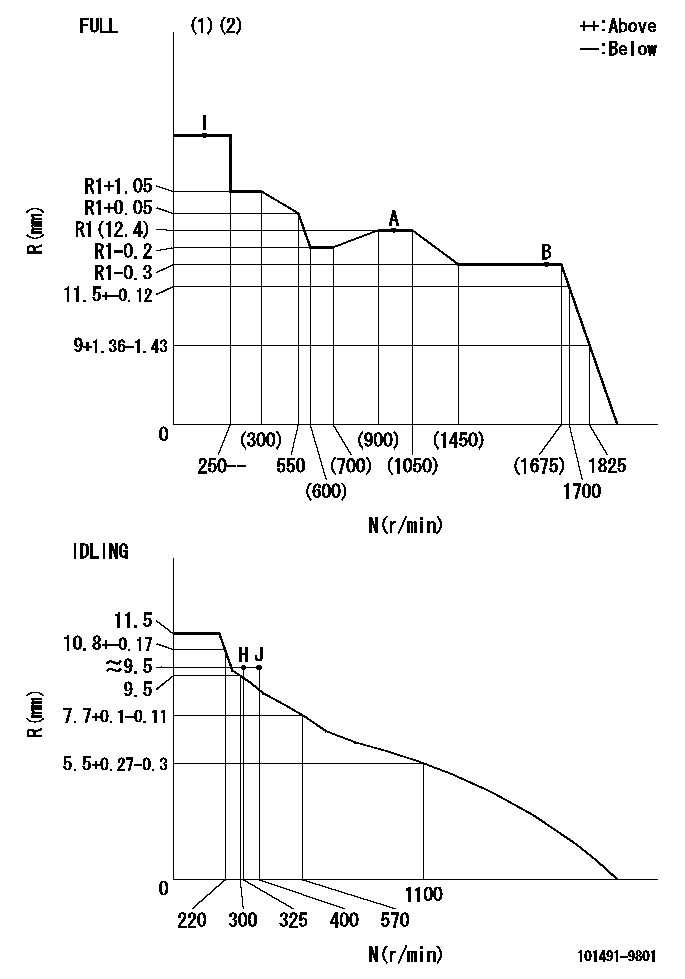

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=G32

----------

----------

T1=G32

----------

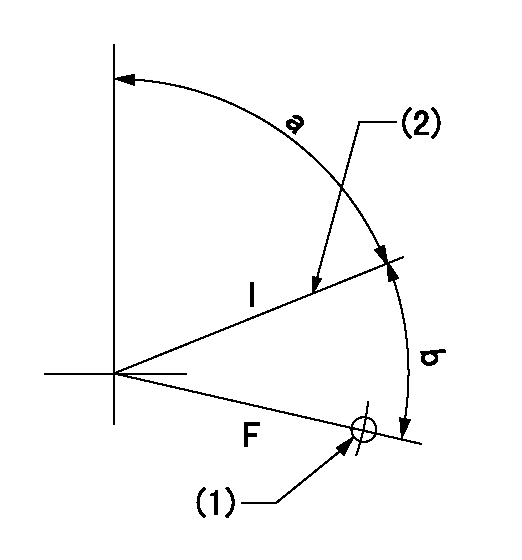

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=32mm

----------

a=71deg+-5deg b=36deg+-3deg

----------

aa=32mm

----------

a=71deg+-5deg b=36deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=12mm

----------

a=29deg+-5deg b=10deg+-5deg

----------

aa=12mm

----------

a=29deg+-5deg b=10deg+-5deg

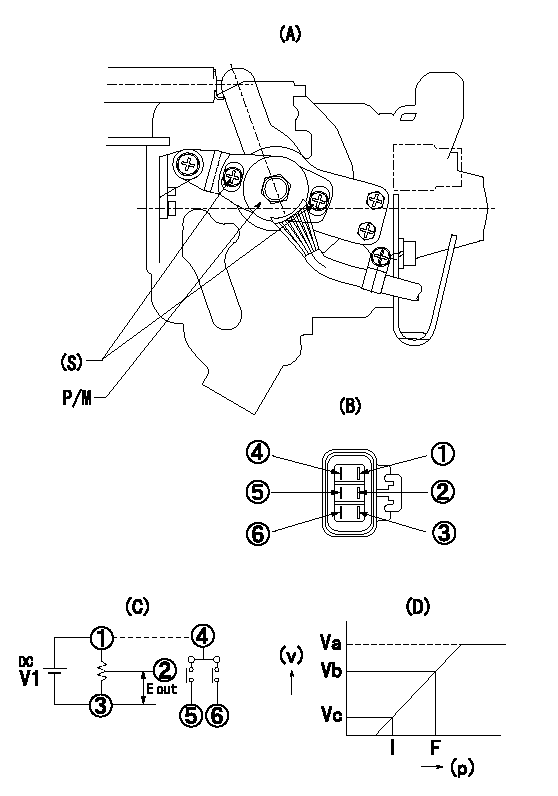

0000001501 POTENTIO METER

(A) : Governor plan view

(B): Potentiometer harness terminal

(C): Potentiometer connection diagram

(D) : Output voltage standard value

(S): Voltage

P/M: potentiometer

(v): output voltage (V)

(p): direction of potentiometer rotation

1. Adjustment procedures

(1)Apply DCV1 to potentiometer harness terminal (B) to obtain the specified output voltage.

(2)Fix the speed lever at the full side.

(3)Loosen the bolt (S), and move the potentiometer from left and right.

(4)Adjust so that the output voltage at full is within the standard values.

(5)Fix bolt (S).

(6)Repeatedly move the speed lever from the full side to the idle side.

(7)Check that it is within the standard values at full and idle.

----------

V1=5+-0.02V

----------

V1=5+-0.02V Va=(5)V Vb=3.71+-0.2V Vc=0.54+-0.3V

----------

V1=5+-0.02V

----------

V1=5+-0.02V Va=(5)V Vb=3.71+-0.2V Vc=0.54+-0.3V

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole (position of gear mark 'S') at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=11deg

----------

a=(60deg)

----------

aa=11deg

----------

a=(60deg)

Information:

Adjust - to conform and correspond to specifications. Check - to observe for satisfactory conditions, accuracy, safety or performance. Exchange - to trade a worn or failing component for a remanufactured or rebuilt component. Inspect - to examine closely, in critical appraisal, while testing or evaluating components or systems. Inspect/Rebuild or Exchange - to examine closely, then making the decision on repair option (i.e. Rebuild or Exchange). Lubricate - to apply a lubricant (oil, grease, etc.) as specified for reducing friction, heat and wear between solid surfaces. Protective Devices - indicators such as gauges, lights, emergency shutoffs, etc., that alert an operator that a potential problem may exist. Failure to respond to these indicators in a timely manner could result in serious engine damage. Rebuild - to repair worn or failing component with new parts, components and/or remanufactured components. Replace - to install something new, remanufactured or rebuilt in place of an existing worn or failing component. Service Hours (Electrical) - records the time (clock hours) the engine is actually running but does not reflect variations in speed, load, etc. Some engines are equipped with mechanical service meters reading in Service Meter Units (SMU). The Maintenance Schedules are developed for clock hours or fuel consumption. For most users, clock hours are the standard interval for maintenance and SMU's can be roughly equal to clock hours. However, Caterpillar recommends that fuel consumption be used as the preferred method of determining intervals rather than SMU's or clock hours.Interval Categories

Engine components can generally be grouped into speed sensitive and load sensitive categories. The maintenance interval for each item listed in the Maintenance Schedule is based on either engine speed or load. Speed sensitive items such as water pumps an air compressors are not primarily affected by the operating load on your engine. The load on an engine will not significantly accelerate the repair or replacement cycle for speed sensitive items. The maintenance intervals established for speed sensitive items are based on service hours. Load sensitive items such as piston rings and cylinder liners are affected by the operating load on your engine. Generally speaking, the lower the load, the longer the engine life. Conversely, the higher the load, the shorter the engine life. A heavy load on an engine will accelerate the repair or replacement cycle for load sensitive items.Load sensitive items are normally internal engine components. The amount of fuel consumed is directly related to the load on your engine.The maintenance interval for load sensitive items includes fuel consumption, since the amount of fuel consumed is directly related to the load on your engine.Caterpillar recommends performing maintenance on load sensitive items at maintenance intervals based on the quantity of fuel consumed.

Engine components can generally be grouped into speed sensitive and load sensitive categories. The maintenance interval for each item listed in the Maintenance Schedule is based on either engine speed or load. Speed sensitive items such as water pumps an air compressors are not primarily affected by the operating load on your engine. The load on an engine will not significantly accelerate the repair or replacement cycle for speed sensitive items. The maintenance intervals established for speed sensitive items are based on service hours. Load sensitive items such as piston rings and cylinder liners are affected by the operating load on your engine. Generally speaking, the lower the load, the longer the engine life. Conversely, the higher the load, the shorter the engine life. A heavy load on an engine will accelerate the repair or replacement cycle for load sensitive items.Load sensitive items are normally internal engine components. The amount of fuel consumed is directly related to the load on your engine.The maintenance interval for load sensitive items includes fuel consumption, since the amount of fuel consumed is directly related to the load on your engine.Caterpillar recommends performing maintenance on load sensitive items at maintenance intervals based on the quantity of fuel consumed.