Information injection-pump assembly

ZEXEL

101491-9271

1014919271

Rating:

Cross reference number

ZEXEL

101491-9271

1014919271

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.5

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

74

73.5

74.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8

6

10

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.5)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

74

73.5

74.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

20

20

Boost pressure

mmHg

150

150

Injection quantity adjustment_04

Adjusting point

B

Rack position

(R1+0.6)

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

87.6

83.6

91.6

Fixing the lever

*

Boost pressure

kPa

20

20

Boost pressure

mmHg

150

150

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

70

85

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

1400

1400

1400

Rack position

R1-0.35

Boost pressure

kPa

2

2

4.7

Boost pressure

mmHg

15

15

35

Boost compensator adjustment_02

Pump speed

r/min

1400

1400

1400

Rack position

R1+0.85

Boost pressure

kPa

11.3

11.3

11.3

Boost pressure

mmHg

85

85

85

Timer adjustment

Pump speed

r/min

850+-25

Advance angle

deg.

1

0.7

1.3

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

925

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1400+-25

Advance angle

deg.

0

0

0

Timer adjustment_04

Pump speed

r/min

1700+-25

Advance angle

deg.

3.5

3.2

3.8

Remarks

Finish

Finish

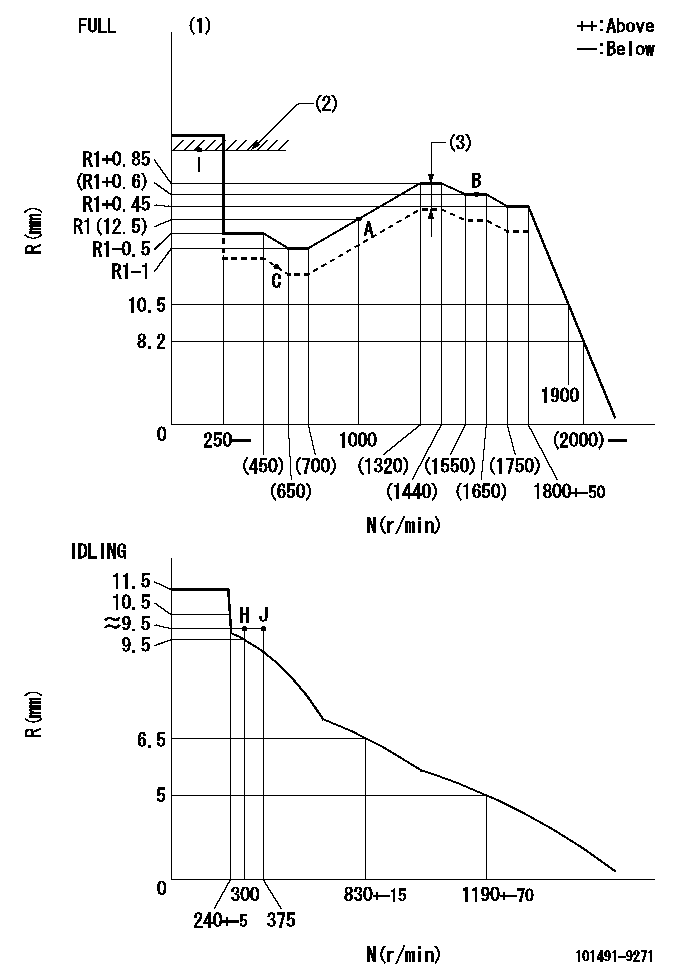

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

(3)Boost compensator stroke: BCL

----------

T1=B80 T1=1.2+-0.1mm

----------

----------

T1=B80 T1=1.2+-0.1mm

----------

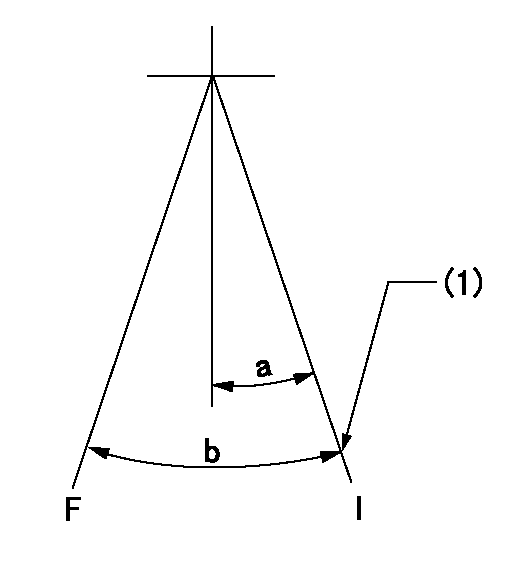

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=20deg+-5deg b=(38deg)+-3deg

----------

----------

a=20deg+-5deg b=(38deg)+-3deg

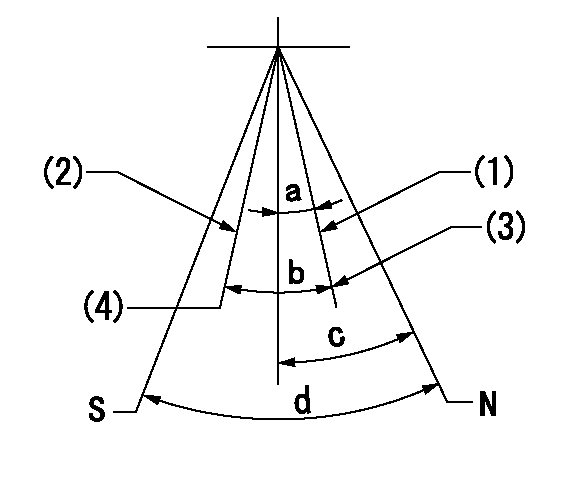

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Stop

(3)Set the normal set bolt.

(4)Set the speed to aa using the idle lever and then confirm non-injection.

----------

aa=300r/min

----------

a=(15deg)+-5deg b=(13.5deg) c=23deg+-5deg d=40deg+-5deg

----------

aa=300r/min

----------

a=(15deg)+-5deg b=(13.5deg) c=23deg+-5deg d=40deg+-5deg

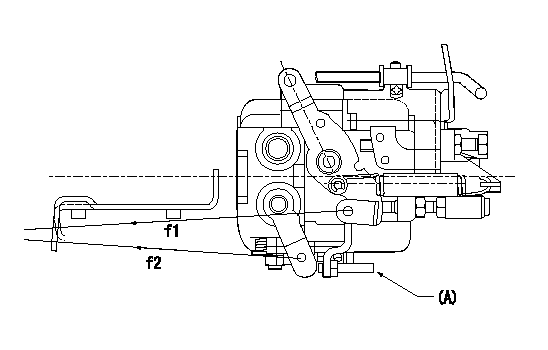

0000001501 LEVER

f1:Direction for pulling the speed lever

f2:Direction for pulling the stop lever

Stop lever's normal position setting method

1. (1) Push in the set bolt (A) until the rack starts to move.

(2)Return the bolt N1 turns from that position and set.

2. Rack with limiter

(1)Return the bolt N1 turns from the rack limit position and set.

----------

N1=1.5

----------

----------

N1=1.5

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(130deg)

----------

----------

a=(130deg)

Information:

Start By:a. remove radiator 1. Remove the four bolts and remove fan blade (1) and extension. 2. Loosen bolts (2) and remove fan belt (4). Loosen clamps (3) and disconnect the two hoses. Remove nut (5) from water pump fan pulley (6). 3. Install tooling (A) and remove fan pulley (6). 4. Remove four bolts (7) and remove the water pump and gasket. At the time of assembly, tighten nut (5) to the torque of 80 N m (60 lb.ft.) Install in the reverse order.Disassemble Water Pump

Start By:a. remove water pump 1. Remove key (1) from the shaft. 2. Remove pump housing (2) from the rear housing. 3. Remove snap ring (3) with tool (A). 4. Put the water pump housing in position on a press. Install tool (B) and remove the shaft assembly from the impeller and water pump housing. 5. Remove seals (4) from the water pump housing if they are damaged. 6. Put shaft assembly (5) in position in a press. Install tool (B) and remove bearings (6) and spacer (7) from the shaft.Assemble Water Pump

1. Put one of the shaft's bearings in position in a press. Make sure there is support for the inner race of the bearing. Push shaft (1) on to bearing (2). 2. Install spacer (4) on the shaft. Put second bearing (3) in position and push the shaft on to it. 3. Install seal (6) and flange (5) in the water pump housing. 4. Put 2S3230 Bearing Lubricant on the bearings. Put the water pump housing in position on a press and install shaft assembly (7) in the housing. 5. Install snap ring (8) over the bearings with tool (A). 6. Install the water seal in the housing with tooling (B). 7. Install seal (9) on the shaft assembly. 8. Install impeller (10) on the shaft with tooling (C) and a press. The clearance between the impeller blade and pump body must be 0.30 to 0.81 mm (.012 to .032 in). 9. Install a new gasket on water pump housing (12). Install housing (12) on the rear housing with nuts (11) that hold it. 10. Install key (13) in the shaft.End By:a. install water pump

Start By:a. remove water pump 1. Remove key (1) from the shaft. 2. Remove pump housing (2) from the rear housing. 3. Remove snap ring (3) with tool (A). 4. Put the water pump housing in position on a press. Install tool (B) and remove the shaft assembly from the impeller and water pump housing. 5. Remove seals (4) from the water pump housing if they are damaged. 6. Put shaft assembly (5) in position in a press. Install tool (B) and remove bearings (6) and spacer (7) from the shaft.Assemble Water Pump

1. Put one of the shaft's bearings in position in a press. Make sure there is support for the inner race of the bearing. Push shaft (1) on to bearing (2). 2. Install spacer (4) on the shaft. Put second bearing (3) in position and push the shaft on to it. 3. Install seal (6) and flange (5) in the water pump housing. 4. Put 2S3230 Bearing Lubricant on the bearings. Put the water pump housing in position on a press and install shaft assembly (7) in the housing. 5. Install snap ring (8) over the bearings with tool (A). 6. Install the water seal in the housing with tooling (B). 7. Install seal (9) on the shaft assembly. 8. Install impeller (10) on the shaft with tooling (C) and a press. The clearance between the impeller blade and pump body must be 0.30 to 0.81 mm (.012 to .032 in). 9. Install a new gasket on water pump housing (12). Install housing (12) on the rear housing with nuts (11) that hold it. 10. Install key (13) in the shaft.End By:a. install water pump