Information injection-pump assembly

ZEXEL

101491-9045

1014919045

Rating:

Cross reference number

ZEXEL

101491-9045

1014919045

Zexel num

Bosch num

Firm num

Name

101491-9045

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.28+-0

.02

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

57.7

57.2

58.2

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H'

Rack position

9.6+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

9

7

11

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

11.28+-0

.5

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

57.7

57.2

58.2

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

11.55+-0

.5

Pump speed

r/min

1700

1700

1700

Average injection quantity

mm3/st.

70

68

72

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

11.39+-0

.5

Pump speed

r/min

625

625

625

Average injection quantity

mm3/st.

42.9

40.9

44.9

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

H

Rack position

9.3+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

7

6.5

7.5

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1350+-25

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1700

Advance angle

deg.

3.5

3.2

3.8

Remarks

Finish

Finish

Test data Ex:

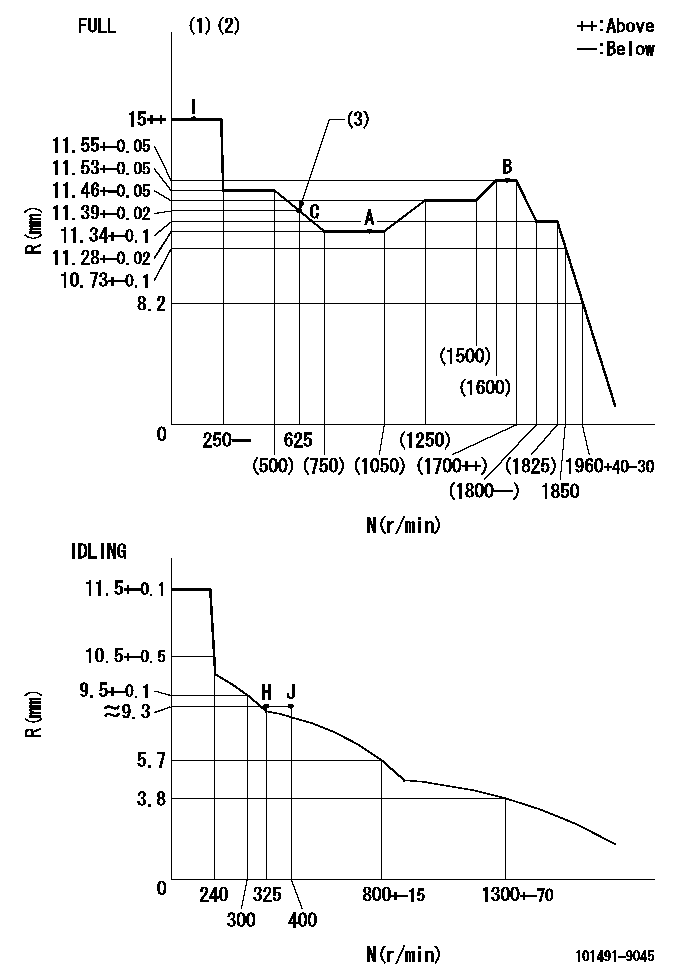

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: R1, speed N1

(3)Torque cam set point

----------

T1=C83 R1=+-0.02mm N1=+-3r/min

----------

----------

T1=C83 R1=+-0.02mm N1=+-3r/min

----------

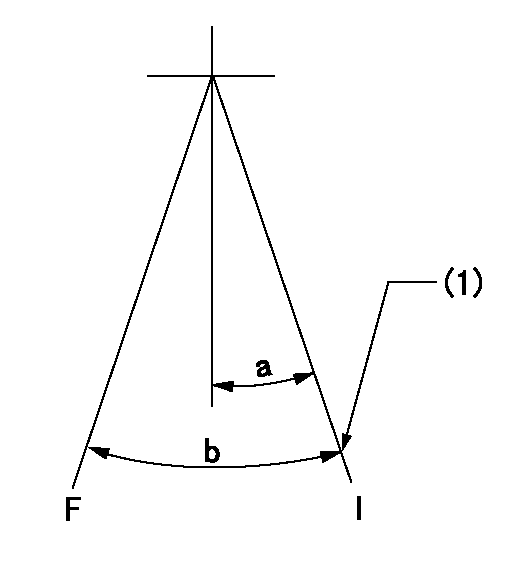

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H' (rack position = aa, speed = bb)

----------

aa=(9.3)mm bb=325r/min

----------

a=20deg+-5deg b=41deg+-3deg

----------

aa=(9.3)mm bb=325r/min

----------

a=20deg+-5deg b=41deg+-3deg

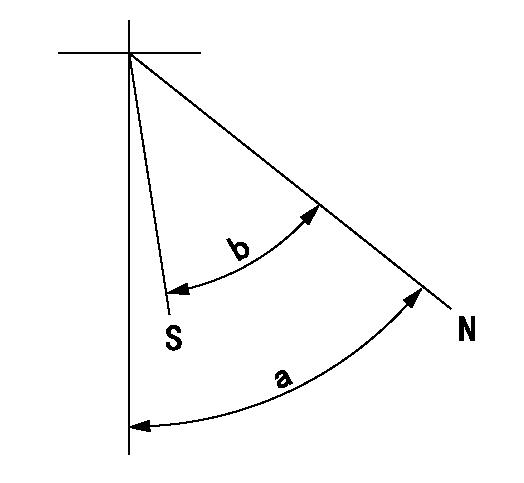

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=40deg+-5deg

----------

----------

a=40deg+-5deg b=40deg+-5deg

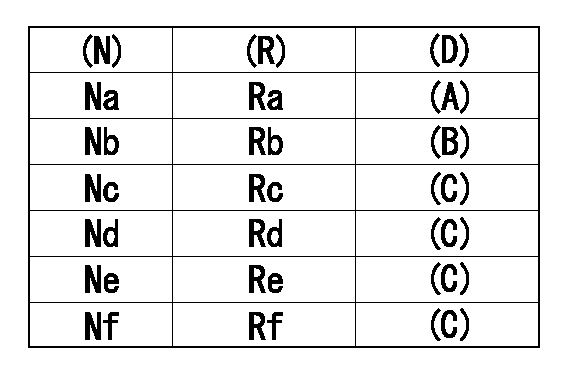

0000001501 GOV RACK POSITION CONFIRM

Confirm the governor adjustment rack position.

Standard point A

Set the torque cam B.

(C) Confirmation

(D) Remarks

(N): Speed of the pump

(R) Rack position (mm)

----------

----------

Na=1000r/min Nb=625r/min Nc=1800r/min Nd=1700r/min Ne=1400r/min Nf=450r/min Ra=11.28+-0.02mm Rb=11.39+-0.02mm Rc=11.34+-0.1mm Rd=11.55+-0.05mm Re=11.46+-0.05mm Rf=11.53+-0.05mm

----------

----------

Na=1000r/min Nb=625r/min Nc=1800r/min Nd=1700r/min Ne=1400r/min Nf=450r/min Ra=11.28+-0.02mm Rb=11.39+-0.02mm Rc=11.34+-0.1mm Rd=11.55+-0.05mm Re=11.46+-0.05mm Rf=11.53+-0.05mm

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(130deg)

----------

----------

a=(130deg)

Information:

Caterpillar: Confidential Yellow

PSP FOR INSTALLING NEW FUEL INJECTION LINE BRACKETS AND CLAMPS ON CERTAIN D8L TRACTORS, D9N TRACTORS, 589 PIPELAYERS, 631E SCR APERS, 637E SCRAPERS, 657E SCRAPERS, 768C TRACTORS, 769C TRUCKS, 834B TRACTORS, AND 988B LOADERS - PS4428 - MAILED US AND CA NADA, CACO, COFA, BRAZIL, CFEL, COSA

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

U-63 A-35 AU-38 B-13 E-39 O-54 1252 PS4428 This Program can be administered either before or after a failure. In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS4428" as Part Number, "7755" as Group Number, and "96" as Description Code. Termination Date

March 31, 1991

Problem

The fuel lines on certain D8L Tractors, D9N Tractors, 589 Pipelayers, 631E Scrapers, 637E Scrapers, 657E Scrapers, 768C Tractors, 769C Trucks, 834B Tractors, and 988B Loaders may fail. New brackets and clamps can be installed to increase the service life of the fuel injection lines.

Affected Product

Model Identification Number D8L 7YB962 7JC778 D9N 1JD1288, 1295, 1296, 1298-1356, 1358, 1361-2039, 2045, 2048, 2049, 2052 589 31Z423-452 631E 1AB965-1198, 1209 637E 1FB361-416, 418, 422 1JB612-724 657E

PSP FOR INSTALLING NEW FUEL INJECTION LINE BRACKETS AND CLAMPS ON CERTAIN D8L TRACTORS, D9N TRACTORS, 589 PIPELAYERS, 631E SCR APERS, 637E SCRAPERS, 657E SCRAPERS, 768C TRACTORS, 769C TRUCKS, 834B TRACTORS, AND 988B LOADERS - PS4428 - MAILED US AND CA NADA, CACO, COFA, BRAZIL, CFEL, COSA

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

U-63 A-35 AU-38 B-13 E-39 O-54 1252 PS4428 This Program can be administered either before or after a failure. In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS4428" as Part Number, "7755" as Group Number, and "96" as Description Code. Termination Date

March 31, 1991

Problem

The fuel lines on certain D8L Tractors, D9N Tractors, 589 Pipelayers, 631E Scrapers, 637E Scrapers, 657E Scrapers, 768C Tractors, 769C Trucks, 834B Tractors, and 988B Loaders may fail. New brackets and clamps can be installed to increase the service life of the fuel injection lines.

Affected Product

Model Identification Number D8L 7YB962 7JC778 D9N 1JD1288, 1295, 1296, 1298-1356, 1358, 1361-2039, 2045, 2048, 2049, 2052 589 31Z423-452 631E 1AB965-1198, 1209 637E 1FB361-416, 418, 422 1JB612-724 657E

Have questions with 101491-9045?

Group cross 101491-9045 ZEXEL

Mazda

101491-9045

INJECTION-PUMP ASSEMBLY