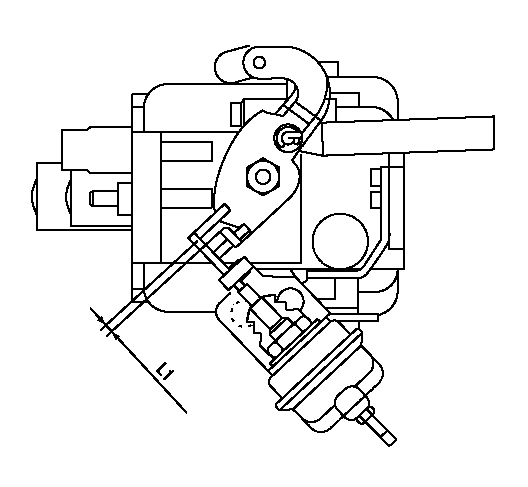

Information injection-pump assembly

ZEXEL

101491-0490

1014910490

ISUZU

8970110150

8970110150

Rating:

Cross reference number

ZEXEL

101491-0490

1014910490

ISUZU

8970110150

8970110150

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.8

3.75

3.85

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

13.2

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

74.1

72.5

75.7

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

10.2

8.9

11.5

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.2)

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

74.1

73.1

75.1

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.45

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

88.4

84.4

92.4

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

92

92

124

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1500

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1800

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

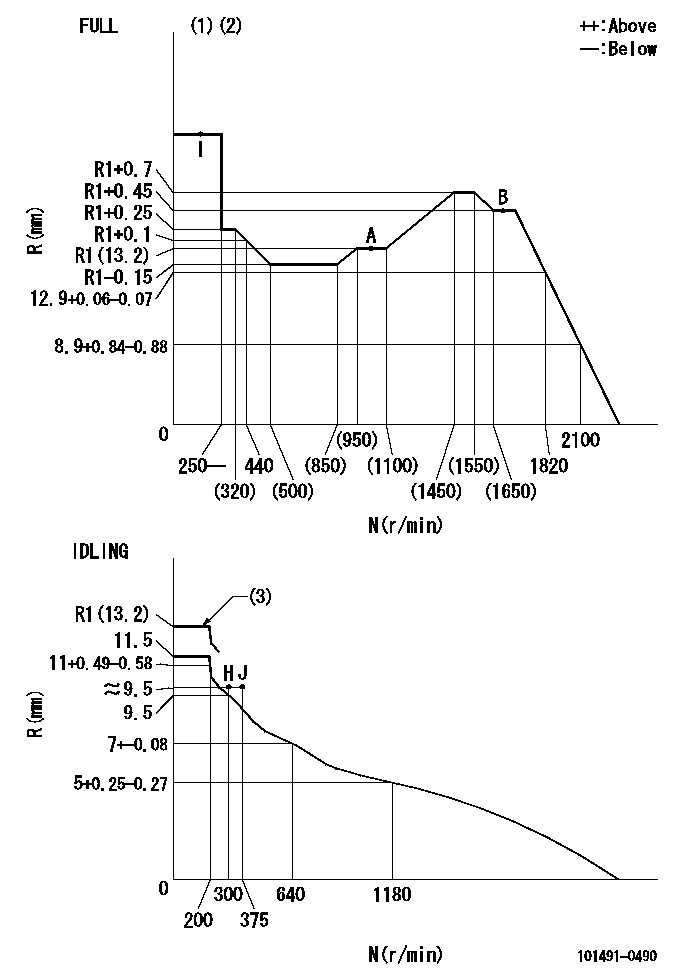

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)At delivery (at R = A, N = N1)

----------

T1=E68 N1=100r/min

----------

----------

T1=E68 N1=100r/min

----------

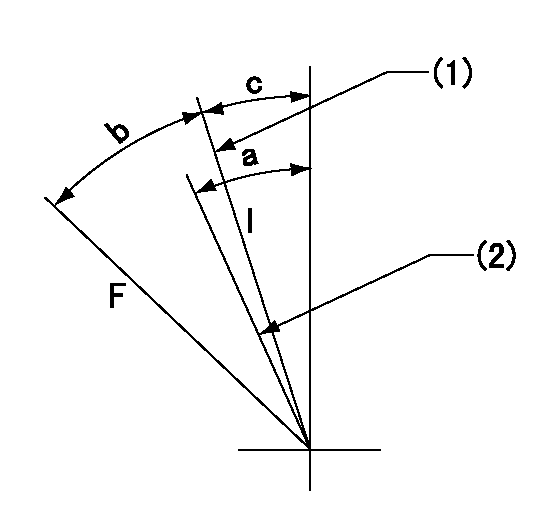

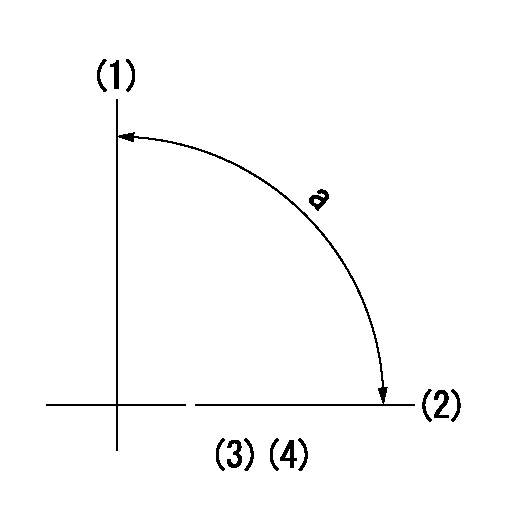

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

(2)Set the idle side stopper bolt at speed = aa and rack position = bb (at delivery)

----------

aa=100r/min bb=R1(13.2)mm

----------

a=(8deg) b=35deg+-3deg c=2.5deg+-5deg

----------

aa=100r/min bb=R1(13.2)mm

----------

a=(8deg) b=35deg+-3deg c=2.5deg+-5deg

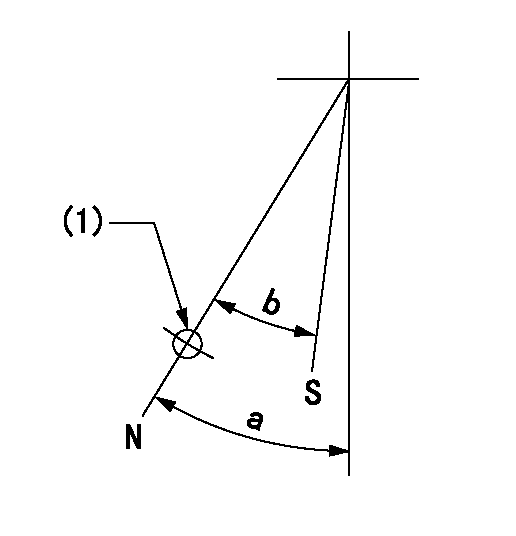

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=64mm

----------

a=45deg+-5deg b=29deg+-5deg

----------

aa=64mm

----------

a=45deg+-5deg b=29deg+-5deg

0000001501 I/P WITH LOAD PLUNGER ADJ

Plunger assembly number: PL (stamping: ST)

1. Adjustment procedures

(1)Insert the pre-stroke adjusting shims L1 for each cylinder.

(2)Adjust injection quantity.(max. var. bet. cyl. idling a1, full a2)

(3)At basic point A, adjust so that the pre-stroke is L2.

(4)Reconfirm the injection quantity.

----------

PL=131154-1820 ST=A260 L1=1mm L2=3.8+-0.05mm a1=+-14% a2=+-2.5%

----------

----------

PL=131154-1820 ST=A260 L1=1mm L2=3.8+-0.05mm a1=+-14% a2=+-2.5%

----------

0000001601 FICD

1. FICD adjustment

(1)FICD adjustment not necessary.

(2)Set the clearance between the actuator rod and speed lever to approx. L1.

----------

L1=3+1mm

----------

----------

L1=3+1mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=15deg

----------

a=(90deg)

----------

aa=15deg

----------

a=(90deg)

Information:

3T6352 Alternator 24V 35A (Delco-Remy Number 1117647)

Load battery with a carbon pile (6V4930 Battery Load Tester) to get maximum alternator output.Polarity ... Negative GroundRotation ... Either DirectionOutput voltage ... 27.5 1.0VSpeed for testing (rpm) ... 5000Output (hot) ... 35APositive output terminal torque ... 6.2 to 8.0 N m (55 to 71 lb in)(1) Ground terminal torque ... 1.7 to 2.9 N m (15 to 26 lb in)(2) Shaft nut torque ... 95 to 110 N m (70 to 80 lb ft) 3T6354 Regulator (Delco-Remy Number 1116405) - Inside Alternator. For use with 3T6352 Alternators

Voltage setting ... No AdjustmentPermissible voltage range ... 26 to 30VBosch

7N9720 Alternator 24V 35A (Bosch Number 0-122-469-001)

Load battery with a carbon pile (6V4930 Battery Load Tester) to get maximum alternator output.Polarity ... Negative GroundRotation ... Either DirectionSpeed for testing (rpm) ... 5000Output voltage ... 27.5 1.0VOutput (hot) ... 35A(1) Torque for pulley nut ... 95 to 110 N m (70 to 80 lb ft)(2) Torque for output terminal B+ ... 17 to 22 N m (13 to 16 lb ft)Torque for ground terminal ... 2.1 to 2.8 N m (19 to 25 lb in) 9G7567 Regulator (Bosch Number 1-197-011-000)-under alternator cover. For use with 7N9720 Alternators.

Voltage setting ... No AdjustmentPermissible voltage range ... 26.7 to 28.3VNippondenso

9G4574 24V 35A (Nippondenso Number 100211-0860)

Load battery with a carbon pile (6V4930 Battery Load Tester) to get maximum alternator output.Polarity ... Negative GroundRotation ... Either DirectionSpeed for testing (rpm) ... 5000Output voltage ... 27.5 1.0VOutput (hot) ... 35A(1) Torque for pulley nut ... 95 to 110 N m (70 to 80 lb ft)(2) Torque for output terminal ... 22 to 37 N m (16 to 27 lb ft)(3) Torque for ground terminal ... 3.4 to 5.4 N m (31 to 49 lb in) 7T2798 Regulator (Nippondenso Number 126000-0380) - Inside Alternator. For use with 9G4574 Alternators.

Voltage setting ... No adjustmentPermissible voltage range ... 26.5 to 28.5V

Load battery with a carbon pile (6V4930 Battery Load Tester) to get maximum alternator output.Polarity ... Negative GroundRotation ... Either DirectionOutput voltage ... 27.5 1.0VSpeed for testing (rpm) ... 5000Output (hot) ... 35APositive output terminal torque ... 6.2 to 8.0 N m (55 to 71 lb in)(1) Ground terminal torque ... 1.7 to 2.9 N m (15 to 26 lb in)(2) Shaft nut torque ... 95 to 110 N m (70 to 80 lb ft) 3T6354 Regulator (Delco-Remy Number 1116405) - Inside Alternator. For use with 3T6352 Alternators

Voltage setting ... No AdjustmentPermissible voltage range ... 26 to 30VBosch

7N9720 Alternator 24V 35A (Bosch Number 0-122-469-001)

Load battery with a carbon pile (6V4930 Battery Load Tester) to get maximum alternator output.Polarity ... Negative GroundRotation ... Either DirectionSpeed for testing (rpm) ... 5000Output voltage ... 27.5 1.0VOutput (hot) ... 35A(1) Torque for pulley nut ... 95 to 110 N m (70 to 80 lb ft)(2) Torque for output terminal B+ ... 17 to 22 N m (13 to 16 lb ft)Torque for ground terminal ... 2.1 to 2.8 N m (19 to 25 lb in) 9G7567 Regulator (Bosch Number 1-197-011-000)-under alternator cover. For use with 7N9720 Alternators.

Voltage setting ... No AdjustmentPermissible voltage range ... 26.7 to 28.3VNippondenso

9G4574 24V 35A (Nippondenso Number 100211-0860)

Load battery with a carbon pile (6V4930 Battery Load Tester) to get maximum alternator output.Polarity ... Negative GroundRotation ... Either DirectionSpeed for testing (rpm) ... 5000Output voltage ... 27.5 1.0VOutput (hot) ... 35A(1) Torque for pulley nut ... 95 to 110 N m (70 to 80 lb ft)(2) Torque for output terminal ... 22 to 37 N m (16 to 27 lb ft)(3) Torque for ground terminal ... 3.4 to 5.4 N m (31 to 49 lb in) 7T2798 Regulator (Nippondenso Number 126000-0380) - Inside Alternator. For use with 9G4574 Alternators.

Voltage setting ... No adjustmentPermissible voltage range ... 26.5 to 28.5V