Information injection-pump assembly

BOSCH

9 400 614 282

9400614282

ZEXEL

101491-0401

1014910401

ISUZU

8943177782

8943177782

Rating:

Service parts 101491-0401 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 282

9400614282

ZEXEL

101491-0401

1014910401

ISUZU

8943177782

8943177782

Zexel num

Bosch num

Firm num

Name

101491-0401

9 400 614 282

8943177782 ISUZU

INJECTION-PUMP ASSEMBLY

4BC2 K

4BC2 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.4

3.35

3.45

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.3

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

56.7

55.1

58.3

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8.6

7.1

10.1

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.3)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

56.7

55.7

57.7

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(10.3)

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

59.6

56.4

62.8

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.1

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

41.9

38.7

45.1

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

56

48

64

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1300--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1250

Advance angle

deg.

0.6

Timer adjustment_03

Pump speed

r/min

1900

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

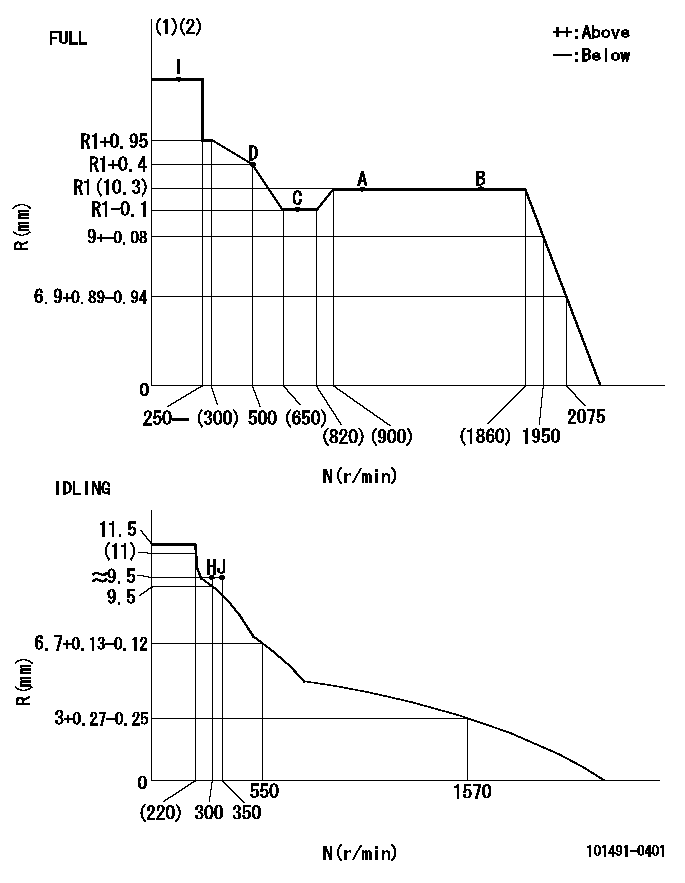

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=D96

----------

----------

T1=D96

----------

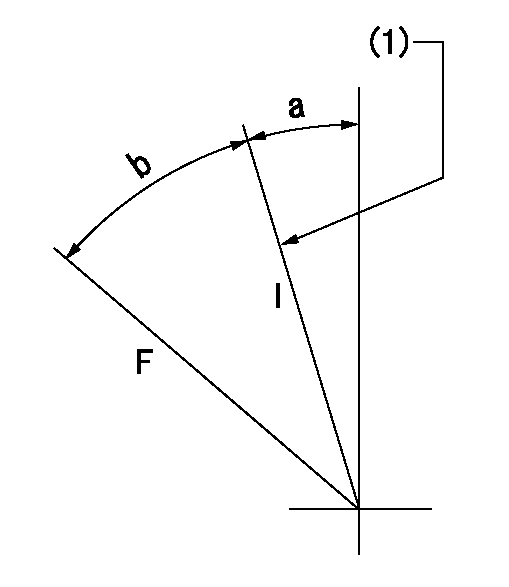

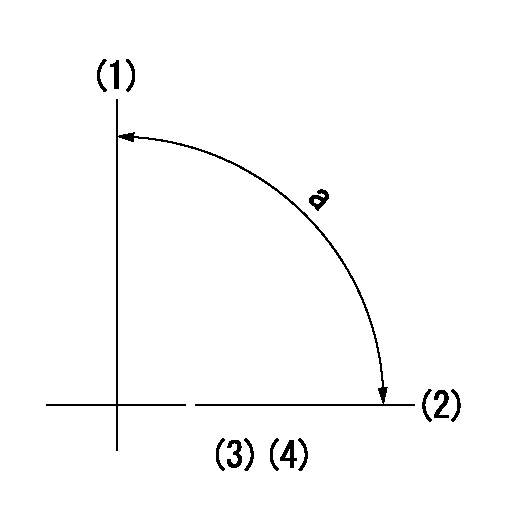

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=5.5deg+-5deg b=36deg+-3deg

----------

----------

a=5.5deg+-5deg b=36deg+-3deg

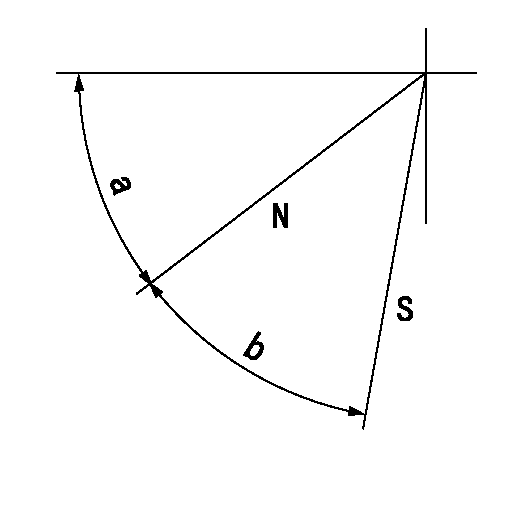

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=45deg+-5deg b=40deg+-5deg

----------

----------

a=45deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=15deg

----------

a=(90deg)

----------

aa=15deg

----------

a=(90deg)

Information:

Always use a wrench to hold the hex fitting on top of the master nozzle, when assembling or disassembling lines. If a wrench is not used, the master nozzle and manifold it is installed into may be damaged.

Check fuel line for "Close-in" Do NOT use fuel lines with an ID (inside diameter) LESS than 1.191 mm (0.0469 in). The fuel line ID can be checked using a 1.2 mm (.047 in) drill.If the drill bit can NOT be inserted into the fuel line high pressure hole, either drill out the line using a 1.6 mm (.063 in) drill or replace the fuel line with a new line. Use the same length and internal diameter lines each time the reference pump is tested.

If the fuel lines are not completely and thoroughly cleaned out after the drilling procedure, metal particles or foreign debris in the line will damage the master nozzles and contaminate the calibration fluid in the test stand.

After the hole has been drilled to the correct size, clean the line with solvent and remove any metal particles. Blow compressed air through the lines, after cleaning, to remove any solvent.

When using pressure air, wear a protective face shield and protective clothing. The maximum air pressure at the nozzle must be less than 205 kPa (30 psi) for cleaning purposes.

9. Identify fuel lines and nozzles in the same order as the reference pump plunger and barrels (1-6 or 1-12) and use the same lines and nozzles each time the reference pump is run on the test bench.10. Select two test points (speeds and shot settings) that will cover the delivery range realized in a dealer's shop.Always set up the test points using only the pump rack zero pin. Do not set the rack full load or idle stops.11. The test stand and reference pump should be run for ten minutes.Make sure test stand pressures and temperatures are within published specifications and that they are stable.12. Set the first test point.Take five samples (draws) and record the individual pump and barrel deliveries for each sample (draw).13. Examine pump and barrel sample data:* Are the samples consistent?The MAXIMUM allowable difference between the HIGH and LOW delivery pump and barrel in the reference pump should be three cc's.If there is NOT a three cc difference, swap pump and barrels in the pump housing (or check master nozzles for damage) and re-test UNTIL the maximum HIGH to LOW

Have questions with 101491-0401?

Group cross 101491-0401 ZEXEL

Isuzu

101491-0401

9 400 614 282

8943177782

INJECTION-PUMP ASSEMBLY

4BC2

4BC2