Information injection-pump assembly

BOSCH

9 400 614 279

9400614279

ZEXEL

101491-0354

1014910354

ISUZU

8944644695

8944644695

Rating:

Service parts 101491-0354 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-94151-865-1

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 279

9400614279

ZEXEL

101491-0354

1014910354

ISUZU

8944644695

8944644695

Zexel num

Bosch num

Firm num

Name

101491-0354

9 400 614 279

8944644695 ISUZU

INJECTION-PUMP ASSEMBLY

4BC2 * K

4BC2 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

56

54.4

57.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

9.7+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

9.5

8

11

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.5)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

56

55

57

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

55

51.8

58.2

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.1

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

42.1

38.9

45.3

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1+0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

41.7

37.7

45.7

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

56

51

61

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1650--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1600

Advance angle

deg.

0.6

Timer adjustment_03

Pump speed

r/min

1800

Advance angle

deg.

3

2.5

3.5

Timer adjustment_04

Pump speed

r/min

1900

Advance angle

deg.

4.5

4

5

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

5

5

5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

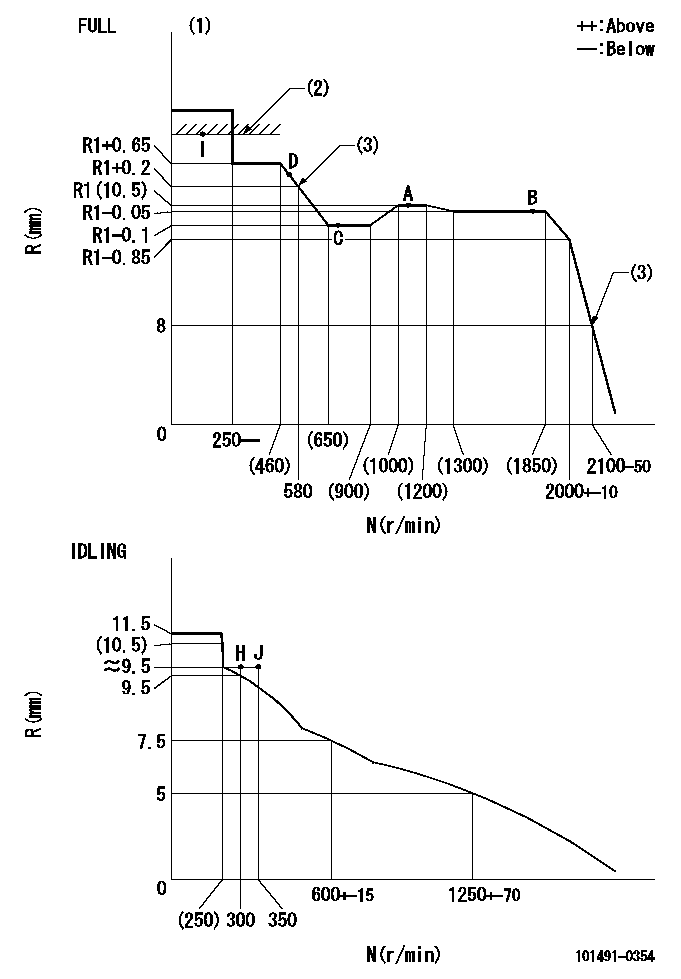

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

(3)The torque cam setting and high idle must be set when speed is increasing from low to high (because of hysterisis).

----------

T1=A73

----------

----------

T1=A73

----------

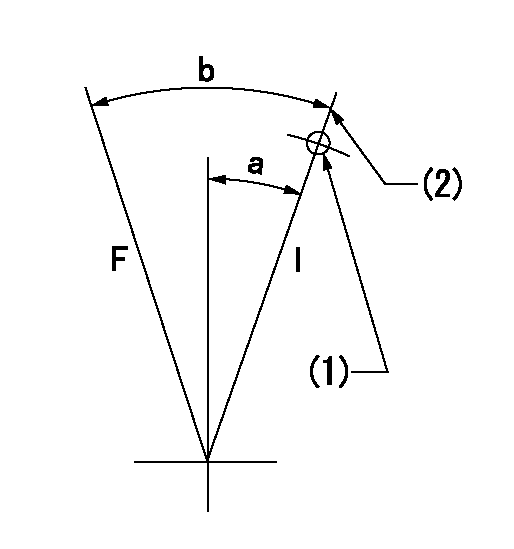

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=50mm

----------

a=29deg+-5deg b=41deg+-3deg

----------

aa=50mm

----------

a=29deg+-5deg b=41deg+-3deg

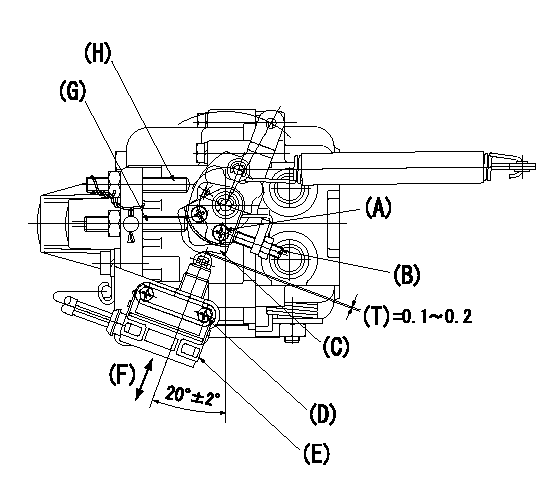

0000001501 MICRO SWITCH

(A) Cam fixing bolt

(B) Screw B

(C) Cam (select)

(D) Microswitch fixing bolt

(E) Microswitch

(F) Adjusting direction

(G) Idle adjusting bolt

(H) Full speed adjusting bolt

(T) Distance

Adjustment of the micro-switch

1. Adjustment specifications

(1)Full side switch ON position

When a thickness gauge is inserted between the speed lever and the full speed adjusting bolt and the speed lever is moved from the idle side to the full side.

Confirm no continuity using a thickness gauge t = 0.3.

Confirm no continuity using a thickness gauge t = 0.1.

(2)Idle side switch ON.

When a thickness gauge is inserted between the speed lever and the idle adjusting bolt and the speed lever is moved from the full side to the idle side.

Confirm no continuity using a thickness gauge t = 1.1.

Confirm no continuity using a thickness gauge t = 0.5.

2. Procedures for adjustment

(1)Standard position for Cam (159226-8100), stamping mark M, is explained in above illustration.

(2)Fix the microswitch body in the position shown in the figure above. (The microswitch is free.)

(3)Full side adjustment

Adjust using screw B to satisfy the adjustment specifications (1) above.

(4)Idle side confirmation

Move the speed lever from the full side to the idle side and confirm the above adjustment specification (2).

(5)When the idle side is not as specified, replace the cam (stamping S or L) and repeat adjustment from procedure 2.(2) above.

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(100deg)

----------

aa=16deg

----------

a=(100deg)

Information:

Introduction

The 6V7020 Nozzle Puller Group can be used as a replacement for the five nozzle puller groups (6V4054, 6V4061, 6V6976, 6V6980 and 6V6981) that are used to remove fuel injection nozzles from the above engines. Some of the parts in the separate tool groups are the same, but in the 6V7020 Nozzle Puller Group only one of each item is included. The 6V7020 Nozzle Puller Group also has several parts and tools that are not in the other five puller groups. See the specific Service Manual nozzle removal procedure. See the information that follows for tool operation.1100, 3100, and 3200 Engine Fuel Injection Nozzles (9L6969, 9L7883, 9L8965, 9L9263, 9N3299, 9N3700, 9N3979, 1W5829)

1. To remove the fuel nozzles from the above engines, disassemble 6V6976 Nozzle Puller Group (1). 2. The tool parts shown above will be needed for nozzle removal.3. Disconnect and remove the rocker shaft, see the Service Manual for procedure. 4. Disconnect fuel line (2) and nozzle fuel line (3), and remove adapter (4) from the cylinder head. Remove bolt (5) and the clamp. 5. Install 6V4151 Leg (6) in the hole with threads where the rocker shaft was fastened. Install 6V4149 Jaw (7) and 6V4152 Screw (8) on fuel nozzle (9). [Jaw (7) will slide into notches in nozzle (9).] 6. Install 6V4150 Leg (10) in 6V4153 Plate (11) and install the plate over leg (6) and screw (8). 7. Install the nut and the washer on screw (8), and using a wrench as shown, remove the nozzle.3300 Engine Fuel Injection Nozzles (7N0449)

1. The tool parts shown above are needed to remove the fuel injection nozzles from this model engine.2. Disconnect the fuel lines and remove the nozzle hold down clamp from both the nozzle to be removed and the nozzle next to it. 3. Install 6V4151 Leg (1) next to the nozzle to be removed. Install 6V4150 Leg (2) in the hole with threads in it by the next nozzle. Put 6V4149 Jaw (3) and 6V4152 Screw (4) on the injector that is to be removed. 4. Put 6V4054 Puller (5) on legs (1) and (2) and install 0S1618 Bolt (6) as shown. Install 1B4206 Nut (7) and 2S5658 Washer on screw (4). Remove the injector.3204 Engine Fuel Injection Nozzles (1W3996)

1. Loosen fuel line (1) and move adapter (2) to get clearance for nozzle removal. Remove bolt (3) and the clamp. 2. Install 6V4152 Screw (4) and 6V6978 Head (5) on the nozzle. Install the remainder of the parts of the nozzle puller group as shown. 3. Be sure 6V6979 Leg (6) is on top of the rocker shaft mount bolt (7). Use a wrench to hold screw (4) so it will not turn while the injector is being removed.3300 Engine Fuel Injection Nozzles (8N7001, 8N7002, 8N7003, 8N7005)

The 6V6980 Nozzle Puller Group is used to remove the fuel injection nozzles for these engines. 1. Disconnect the fuel line and remove the hold down clamp and bolt from the nozzle, but do not remove the nozzle

The 6V7020 Nozzle Puller Group can be used as a replacement for the five nozzle puller groups (6V4054, 6V4061, 6V6976, 6V6980 and 6V6981) that are used to remove fuel injection nozzles from the above engines. Some of the parts in the separate tool groups are the same, but in the 6V7020 Nozzle Puller Group only one of each item is included. The 6V7020 Nozzle Puller Group also has several parts and tools that are not in the other five puller groups. See the specific Service Manual nozzle removal procedure. See the information that follows for tool operation.1100, 3100, and 3200 Engine Fuel Injection Nozzles (9L6969, 9L7883, 9L8965, 9L9263, 9N3299, 9N3700, 9N3979, 1W5829)

1. To remove the fuel nozzles from the above engines, disassemble 6V6976 Nozzle Puller Group (1). 2. The tool parts shown above will be needed for nozzle removal.3. Disconnect and remove the rocker shaft, see the Service Manual for procedure. 4. Disconnect fuel line (2) and nozzle fuel line (3), and remove adapter (4) from the cylinder head. Remove bolt (5) and the clamp. 5. Install 6V4151 Leg (6) in the hole with threads where the rocker shaft was fastened. Install 6V4149 Jaw (7) and 6V4152 Screw (8) on fuel nozzle (9). [Jaw (7) will slide into notches in nozzle (9).] 6. Install 6V4150 Leg (10) in 6V4153 Plate (11) and install the plate over leg (6) and screw (8). 7. Install the nut and the washer on screw (8), and using a wrench as shown, remove the nozzle.3300 Engine Fuel Injection Nozzles (7N0449)

1. The tool parts shown above are needed to remove the fuel injection nozzles from this model engine.2. Disconnect the fuel lines and remove the nozzle hold down clamp from both the nozzle to be removed and the nozzle next to it. 3. Install 6V4151 Leg (1) next to the nozzle to be removed. Install 6V4150 Leg (2) in the hole with threads in it by the next nozzle. Put 6V4149 Jaw (3) and 6V4152 Screw (4) on the injector that is to be removed. 4. Put 6V4054 Puller (5) on legs (1) and (2) and install 0S1618 Bolt (6) as shown. Install 1B4206 Nut (7) and 2S5658 Washer on screw (4). Remove the injector.3204 Engine Fuel Injection Nozzles (1W3996)

1. Loosen fuel line (1) and move adapter (2) to get clearance for nozzle removal. Remove bolt (3) and the clamp. 2. Install 6V4152 Screw (4) and 6V6978 Head (5) on the nozzle. Install the remainder of the parts of the nozzle puller group as shown. 3. Be sure 6V6979 Leg (6) is on top of the rocker shaft mount bolt (7). Use a wrench to hold screw (4) so it will not turn while the injector is being removed.3300 Engine Fuel Injection Nozzles (8N7001, 8N7002, 8N7003, 8N7005)

The 6V6980 Nozzle Puller Group is used to remove the fuel injection nozzles for these engines. 1. Disconnect the fuel line and remove the hold down clamp and bolt from the nozzle, but do not remove the nozzle

Have questions with 101491-0354?

Group cross 101491-0354 ZEXEL

Isuzu

101491-0354

9 400 614 279

8944644695

INJECTION-PUMP ASSEMBLY

4BC2

4BC2