Information injection-pump assembly

BOSCH

9 400 614 265

9400614265

ZEXEL

101482-9322

1014829322

YANMAR

12990451500

12990451500

Rating:

Cross reference number

BOSCH

9 400 614 265

9400614265

ZEXEL

101482-9322

1014829322

YANMAR

12990451500

12990451500

Zexel num

Bosch num

Firm num

Name

101482-9322

9 400 614 265

12990451500 YANMAR

INJECTION-PUMP ASSEMBLY

4TNE92 K

4TNE92 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.8

2.75

2.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

8

Pump speed

r/min

1225

1225

1225

Average injection quantity

mm3/st.

34.9

33.9

35.9

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.5+-0.5

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

10

9

11

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

10.2++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

35

35

45

Fixing the lever

*

Rack limit

*

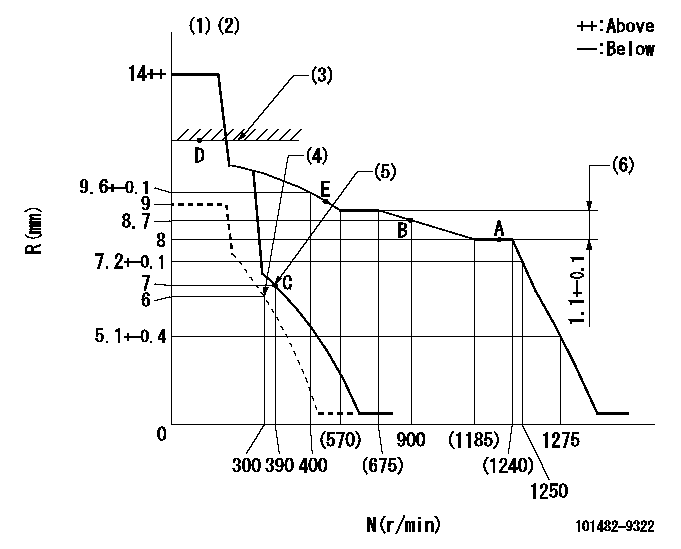

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

----------

K=8 N1=1225r/min N2=650r/min

----------

----------

K=8 N1=1225r/min N2=650r/min

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=6deg+-5deg b=28deg+-5deg

----------

----------

a=6deg+-5deg b=28deg+-5deg

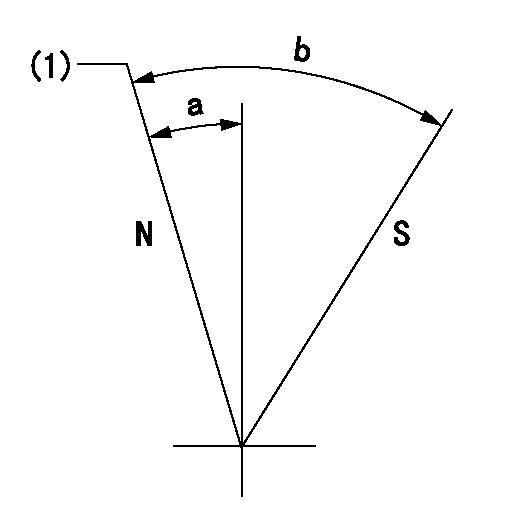

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=7deg+-5deg b=53deg+-5deg

----------

----------

a=7deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Removal of idler gearCamshaft End Play

Measure the camshaft end play, and, if the limit value is exceeded, replace the thrust plate.

Measurement of camshaft end playReversal of Crankcase

Gently lay the crankcase on its side, then turn the crankcase upside down.

Resting the crankcase with the oil pan on the bottom can cause the oil pan to crack.

Reversal of crankcaseRemoval of Oil Pan And Oil Pan Gasket

(1) Unscrew the oil pan mounting bolts, and detach the oil pan.(2) Remove the oil pan gasket.

Removal of oil pan and oil gasketRemoval of Oil Pump

Unscrew the oil pump set bolt, and pull out the oil pump.

Removal of oil pumpRemoval of Camshaft

Removal of camshaft(1) Position the camshaft gear so that the two lightening holes are on the top and bottom, then remove the thrust plate mounting bolts using the socket.(2) Pull out the camshaft from the crankcase.

Be careful not to damage the cams and bearing sections on the camshaft.

Removal of Front Plate

Removal of front plateUnscrew the front plate mounting bolts, and dismount the front plate (together with the injection pump) from the crankcase.Pistons, Connecting Rods, Crankshaft and Crankcase

When replacing the crankcase, remove all accessories (relief valve and others) carefully from the crankcase, and reinstall them on a new crankcase.Laying Crankcase on Its Side

Gently lay the crankcase on its side.

Laying crankcase on its sideMeasurement of Connecting Rod End Play

(1) Measure the clearance between the big-end of each connecting rod and the crankshaft (end play) with feeler gages. (2) If the measured clearance exceeds the limit value, replace the connecting rod.

Measurement of connecting rod End PlayRemoval of Connecting Rod Caps

(1) On each connecting rod and cap, put a mark indicating its cylinder No.(2) Remove the connecting rod caps.(3) For each removed connecting rod bearing (lower half), indicate the piston No. from which it was removed and the upper/lower identification. Be careful not to damage the bearings. Arrange the removed bearings in such a way that they can be reinstalled in their original positions during reassembly.

Removal of connecting rod capPreparation For Removal of Pistons

If carbon deposits are present at the upper sections of the cylinders, remove the carbon deposits with sandpaper and a cloth to facilitate piston removal.

Preparation for removal of pistonRemoval of Pistons

(1) Turn the crankshaft to bring the piston to be removed to the top dead center.(2) Using the wooden handle of a hammer, push the connecting rod on the cap contacting surface to remove the piston and connecting rod assembly from the top side of the cylinder.

Removal of pistonRemoval of Piston Ring

Using the piston ring pliers, remove the piston rings

Removal of piston ringRemoval of Piston Pins

Removal of piston pin(1) Using the snap ring pliers, remove the snap rings.(2) Pull out the piston pin, and separate the piston from the connecting rod.(3) If the piston pin cannot be remove easily, heat the piston with a piston heater or in hot water.Reversal of Crankcase

Gently stand the crankcase so that the oil pan mounting side faces up.

Reversal of crankcaseMeasurement of Crankshaft End Play

(1) With a dial gage positioned

Have questions with 101482-9322?

Group cross 101482-9322 ZEXEL

Dpico

Nissan-Diesel

Yanmar

101482-9322

9 400 614 265

12990451500

INJECTION-PUMP ASSEMBLY

4TNE92

4TNE92