Information injection-pump assembly

ZEXEL

101482-9131

1014829131

NISSAN-DIESEL

1679090313

1679090313

Rating:

Cross reference number

ZEXEL

101482-9131

1014829131

NISSAN-DIESEL

1679090313

1679090313

Zexel num

Bosch num

Firm num

Name

101482-9131

1679090313 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FD35T04 * K

FD35T04 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.8

2.75

2.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

67.2

66.2

68.2

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.8+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

10

8

12

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

81

81

91

Fixing the lever

*

Rack limit

*

Test data Ex:

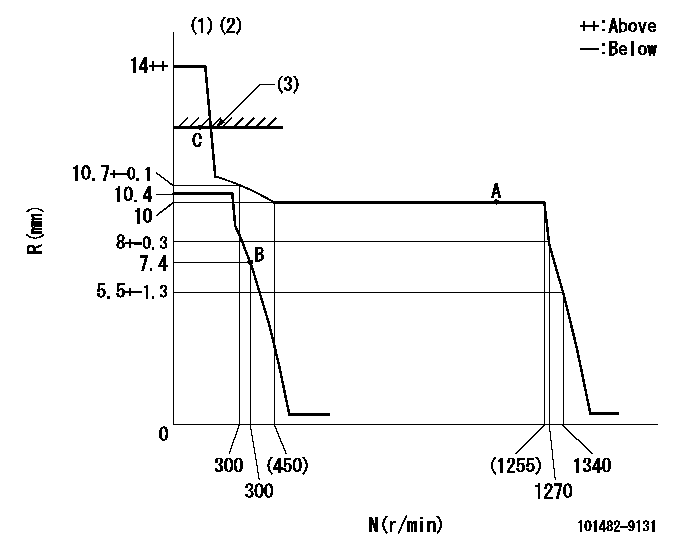

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

K=10

----------

----------

K=10

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(16deg)+-5deg b=(36deg)+-5deg

----------

----------

a=(16deg)+-5deg b=(36deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Maximum no-load speed (r/min)

LABEL9:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)At high idle rack position L

----------

L=5.5mm

----------

a1=A a2=B a3=C a4=- r1=- r2=1100r/min r3=- r4=- Q1=- Q2=67.2+-1mm3/st Q3=- Q4=- c1=- c2=+-3.5% c3=- c4=- a5=25 a6=24 a7=23 a8=22 a9=21 a10=20 a11=19 a12=18 a13=17 a14=16 a15=15 r5=1250r/min r6=1200r/min r7=1150r/min r8=1100r/min r9=1050r/min r10=1000r/min r11=950r/min r12=900r/min r13=850r/min r14=800r/min r15=750r/min R5=1340+-31r/min R6=1290+-30r/min R7=1235+-28r/min R8=1180+-27r/min R9=1130+-26r/min R10=1075+-25r/min R11=1040+-24r/min R12=995+-22r/min R13=950+-20r/min R14=905+-20r/min R15=860+-18r/min

----------

L=5.5mm

----------

a1=A a2=B a3=C a4=- r1=- r2=1100r/min r3=- r4=- Q1=- Q2=67.2+-1mm3/st Q3=- Q4=- c1=- c2=+-3.5% c3=- c4=- a5=25 a6=24 a7=23 a8=22 a9=21 a10=20 a11=19 a12=18 a13=17 a14=16 a15=15 r5=1250r/min r6=1200r/min r7=1150r/min r8=1100r/min r9=1050r/min r10=1000r/min r11=950r/min r12=900r/min r13=850r/min r14=800r/min r15=750r/min R5=1340+-31r/min R6=1290+-30r/min R7=1235+-28r/min R8=1180+-27r/min R9=1130+-26r/min R10=1075+-25r/min R11=1040+-24r/min R12=995+-22r/min R13=950+-20r/min R14=905+-20r/min R15=860+-18r/min

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole (position of gear mark 'P') at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(60deg)

----------

aa=14deg

----------

a=(60deg)

Information:

Overview of Radiator-Equipped Engine's Cooling System

Flow of coolantWater Pump

Removal and Inspection

Removal sequence and points to check on water pump(1) Cooling fan(2) Fan spacer(3) Water pump pulley(4) Fan belt(5) Water bypass hose(6) Water pump assembly Key Points for RemovalRemoval of the water pump pulley and fa belt is possible after loosening slightly both the adjusting bolt (1) and support bolt (2). This allows the alternator to be moved and then the V-belt slackened.

Removing water pump pulley Key Points for InspectionTurn the pump by hand to check the impeller shaft for smooth and quiet rotation. If irregular or noisy rotation is detected, replace them as an assembly.

Inspecting impeller and shaft rotationInstallation

Perform installation by following the removal sequence in reverse: Key Points for Inspection(1) Install the six water pump mounting bolts in their correct locations by referring to the figure on the right for the nominal diameters and lengths from bottom of head.

Correct locations of water pump mounting bolts(2) Use a new gasket when installing the water pump.(3) Adjust the fan belt tension according to the following specification.Unit: mm (in.)

Fan belt tension adjustmentThermostat

Disassembly

Removal sequence and points to check on the thermostat(1) Water hose(2) Water outlet fitting(3) Thermostat(4) Thermostat fitting(5) Thermo switchInspection

Key Points for Removal(1) Operation Test of Thermostat

Put the thermostat in a container of water. Heat the water and record both of the temperatures at which the valve starts to open and at which the valve lift reaches 8 mm (0.3 in.). If the readings do not conform to the specification below, replace the thermostat.

Operation test of thermostat

Carry out this operation with extreme care to avoid burns and prevent fire.

Installation

Except that the instructions shown below are to be followed, perform installation by following the removal sequence in reverse: Key Points for Inspection(1) Thermo Switch

Apply sealant to the threads an tighten to the specified torque.

Installing thermo switch(1) Thermostat

Make sure that the thermostat flange fits correctly into the counterbore in the thermostat fitting.

Installing thermostat

Flow of coolantWater Pump

Removal and Inspection

Removal sequence and points to check on water pump(1) Cooling fan(2) Fan spacer(3) Water pump pulley(4) Fan belt(5) Water bypass hose(6) Water pump assembly Key Points for RemovalRemoval of the water pump pulley and fa belt is possible after loosening slightly both the adjusting bolt (1) and support bolt (2). This allows the alternator to be moved and then the V-belt slackened.

Removing water pump pulley Key Points for InspectionTurn the pump by hand to check the impeller shaft for smooth and quiet rotation. If irregular or noisy rotation is detected, replace them as an assembly.

Inspecting impeller and shaft rotationInstallation

Perform installation by following the removal sequence in reverse: Key Points for Inspection(1) Install the six water pump mounting bolts in their correct locations by referring to the figure on the right for the nominal diameters and lengths from bottom of head.

Correct locations of water pump mounting bolts(2) Use a new gasket when installing the water pump.(3) Adjust the fan belt tension according to the following specification.Unit: mm (in.)

Fan belt tension adjustmentThermostat

Disassembly

Removal sequence and points to check on the thermostat(1) Water hose(2) Water outlet fitting(3) Thermostat(4) Thermostat fitting(5) Thermo switchInspection

Key Points for Removal(1) Operation Test of Thermostat

Put the thermostat in a container of water. Heat the water and record both of the temperatures at which the valve starts to open and at which the valve lift reaches 8 mm (0.3 in.). If the readings do not conform to the specification below, replace the thermostat.

Operation test of thermostat

Carry out this operation with extreme care to avoid burns and prevent fire.

Installation

Except that the instructions shown below are to be followed, perform installation by following the removal sequence in reverse: Key Points for Inspection(1) Thermo Switch

Apply sealant to the threads an tighten to the specified torque.

Installing thermo switch(1) Thermostat

Make sure that the thermostat flange fits correctly into the counterbore in the thermostat fitting.

Installing thermostat

Have questions with 101482-9131?

Group cross 101482-9131 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

101482-9131

1679090313

INJECTION-PUMP ASSEMBLY

FD35T04

FD35T04