Information injection-pump assembly

ZEXEL

101482-9010

1014829010

Rating:

Cross reference number

ZEXEL

101482-9010

1014829010

Zexel num

Bosch num

Firm num

Name

101482-9010

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.8

2.75

2.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.5

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

61.6

60.6

62.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

84

84

Boost pressure

mmHg

630

630

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

28.3

24.3

32.3

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

10

8

12

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_04

Adjusting point

D

Rack position

13.3+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

81

71

91

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

9.5

Boost pressure

kPa

12

10.7

13.3

Boost pressure

mmHg

90

80

100

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

10.5

Boost pressure

kPa

70.6

63.9

77.3

Boost pressure

mmHg

530

480

580

Test data Ex:

Governor adjustment

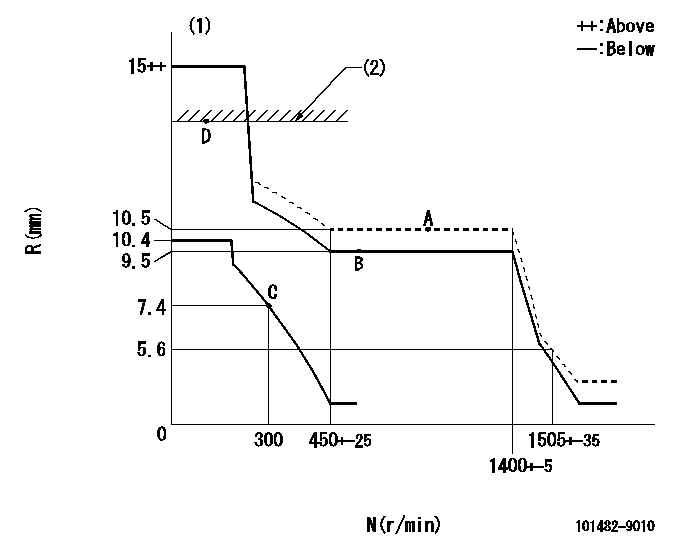

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

----------

K=10

----------

----------

K=10

----------

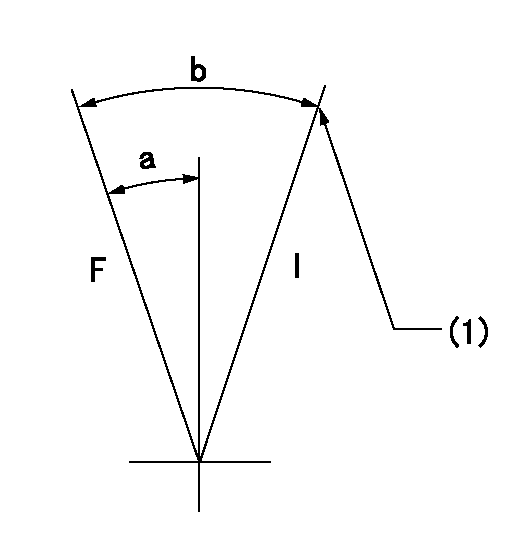

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=11deg+-5deg b=27deg+-5deg

----------

----------

a=11deg+-5deg b=27deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=16.5deg+-5deg b=50deg+-5deg

----------

----------

a=16.5deg+-5deg b=50deg+-5deg

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Maximum no-load speed (r/min)

LABEL9:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)At high idle rack position L

----------

L=5.6mm

----------

a1=A a2=B a3=- a4=- r1=1100r/min r2=1000r/min r3=- r4=- Q1=68.8+-1mm3/st Q2=61.6+-1mm3/st Q3=- Q4=- c1=+-2.5% c2=+-2.5% c3=- c4=- a5=28 a6=27 a7=26 a8=25 a9=24 a10=23 a11=22 a12=21 a13=20 a14=- a15=- r5=1400r/min r6=1350r/min r7=1300r/min r8=1250r/min r9=1200r/min r10=1150r/min r11=1100r/min r12=1050r/min r13=1000r/min r14=- r15=- R5=1505+-35r/min R6=1450+-33r/min R7=1395+-32r/min R8=1340+-31r/min R9=1290+-30r/min R10=1235+-28r/min R11=1180+-27r/min R12=1130+-26r/min R13=1075+-25r/min R14=- R15=-

----------

L=5.6mm

----------

a1=A a2=B a3=- a4=- r1=1100r/min r2=1000r/min r3=- r4=- Q1=68.8+-1mm3/st Q2=61.6+-1mm3/st Q3=- Q4=- c1=+-2.5% c2=+-2.5% c3=- c4=- a5=28 a6=27 a7=26 a8=25 a9=24 a10=23 a11=22 a12=21 a13=20 a14=- a15=- r5=1400r/min r6=1350r/min r7=1300r/min r8=1250r/min r9=1200r/min r10=1150r/min r11=1100r/min r12=1050r/min r13=1000r/min r14=- r15=- R5=1505+-35r/min R6=1450+-33r/min R7=1395+-32r/min R8=1340+-31r/min R9=1290+-30r/min R10=1235+-28r/min R11=1180+-27r/min R12=1130+-26r/min R13=1075+-25r/min R14=- R15=-

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole (position of gear mark 'B') at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(60deg)

----------

aa=14deg

----------

a=(60deg)

Information:

GENERAL

1. Schematic

Schematic2. Specifications (standard) INSPECTION

Inspection points1. Water pump Check the impeller and shaft for rotation. If they do not rotate freely or have noise, replace the water pump assembly.

Checking water pump2. Thermostat (standard) Hang the thermostat in the pan of water as shown in the illustration. The thermostat must be below the surface of the water and its must be away from the sides of the pan. Heat the water uniformly in the pan and measure a temperature at which the valve starts opening and a temperature at which the valve lift (distance) is 8 mm (0.3 in.). Replace the thermostat if defective.

Water in the pan is hot. Any contact can cause severe burns.

Testing thermostat3. Thermoswitch (standard) Hang the thermoswitch in the pan of oil with its temperature sensing end below the surface of oil and measure the resistance while heating the oil as shown in the illustration. If the resistance is incorrect, replace the thermoswitch.

Oil in the pan is hot. Any contact can cause severe burns.

Testing thermoswitch4. Thermounit (standard) Hang the thermounit in the pan of antifreeze with its temperature sensing end below the surface of antifreeze and measure the resistance while heating the antifreeze as shown in the illustration. If the resistance is incorrect, replace the thermounit.

Antifreeze in the pan is hot. Any contact can cause severe burns.

Testing thermounit

1. Schematic

Schematic2. Specifications (standard) INSPECTION

Inspection points1. Water pump Check the impeller and shaft for rotation. If they do not rotate freely or have noise, replace the water pump assembly.

Checking water pump2. Thermostat (standard) Hang the thermostat in the pan of water as shown in the illustration. The thermostat must be below the surface of the water and its must be away from the sides of the pan. Heat the water uniformly in the pan and measure a temperature at which the valve starts opening and a temperature at which the valve lift (distance) is 8 mm (0.3 in.). Replace the thermostat if defective.

Water in the pan is hot. Any contact can cause severe burns.

Testing thermostat3. Thermoswitch (standard) Hang the thermoswitch in the pan of oil with its temperature sensing end below the surface of oil and measure the resistance while heating the oil as shown in the illustration. If the resistance is incorrect, replace the thermoswitch.

Oil in the pan is hot. Any contact can cause severe burns.

Testing thermoswitch4. Thermounit (standard) Hang the thermounit in the pan of antifreeze with its temperature sensing end below the surface of antifreeze and measure the resistance while heating the antifreeze as shown in the illustration. If the resistance is incorrect, replace the thermounit.

Antifreeze in the pan is hot. Any contact can cause severe burns.

Testing thermounit

Have questions with 101482-9010?

Group cross 101482-9010 ZEXEL

Daewoo

101482-9010

INJECTION-PUMP ASSEMBLY