Information injection-pump assembly

BOSCH

9 400 611 687

9400611687

ZEXEL

101482-4351

1014824351

ISUZU

8943811481

8943811481

Rating:

Service parts 101482-4351 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-94122-262-5

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 687

9400611687

ZEXEL

101482-4351

1014824351

ISUZU

8943811481

8943811481

Zexel num

Bosch num

Firm num

Name

101482-4351

9 400 611 687

8943811481 ISUZU

INJECTION-PUMP ASSEMBLY

4JB1 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4JB1 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-2

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

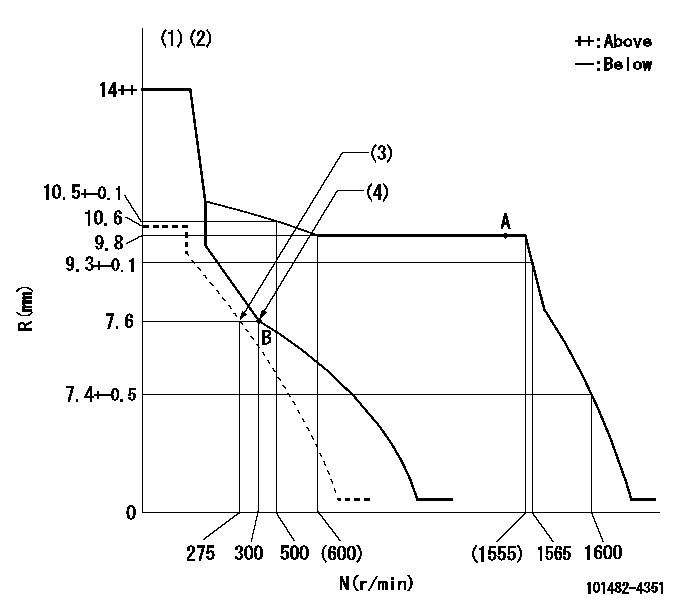

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

49.7

48.7

50.7

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.6+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8

6

10

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Set idle sub-spring

(4)Main spring setting

----------

K=7

----------

----------

K=7

----------

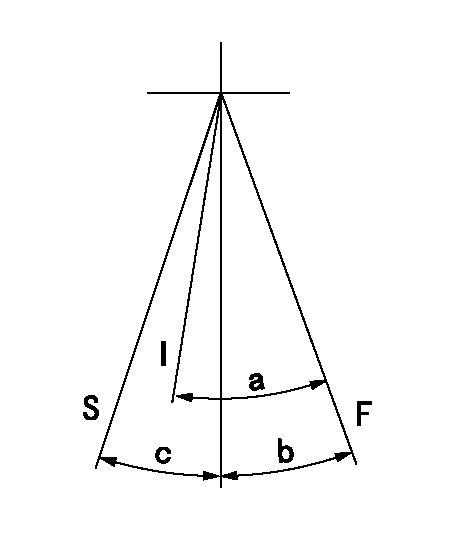

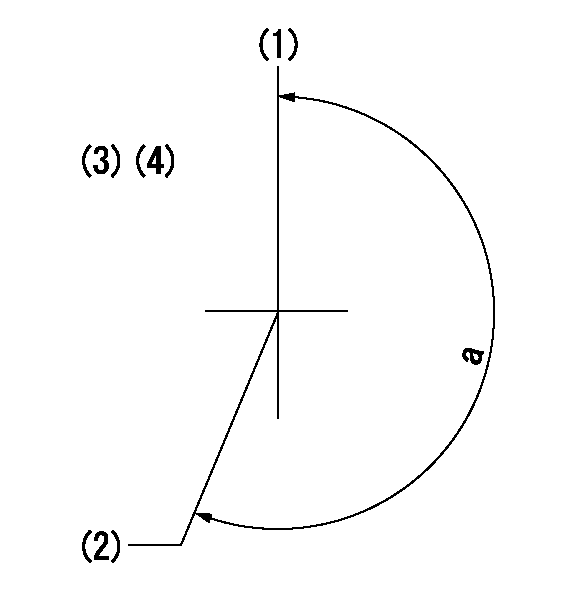

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=29deg+-5deg b=11deg+-5deg c=32deg+-3deg

----------

----------

a=29deg+-5deg b=11deg+-5deg c=32deg+-3deg

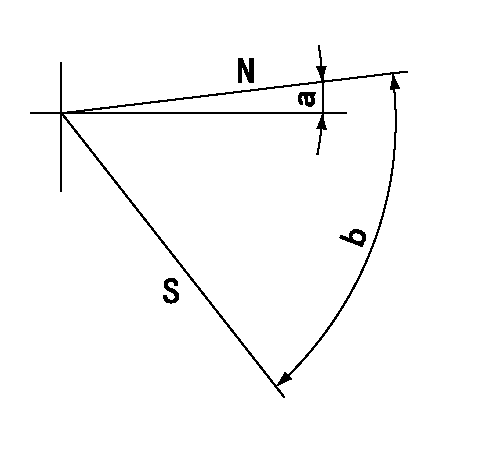

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=0deg+-5deg b=53deg+-5deg

----------

----------

a=0deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'V' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=20deg

----------

a=(200deg)

----------

aa=20deg

----------

a=(200deg)

Information:

General Information

Fig. 1-Engine Balancer ShaftsTwo types of balancer shafts are used (Fig. 1). They are mounted in the lower half of the cylinder block and each rotates in three pressure-lubricated replaceable bushings.The balancer shafts rotate in opposite directions to reduce engine vibration. Thrust of the balancer shafts is absorbed by thrust plates fastened to the front of the cylinder block.Removal

Remove fan belts, alternator, and fan.Remove oil pan.Disconnect oil cooler lines.Use a pulley puller to remove the crankshaft pulley.Remove the timing gear cover.Remove weights (2, Fig. 1), from the balancer shafts, if equipped.Remove oil pump gear and lower idler gear.Remove balancer shafts and identify as left and right.Remove balancer shaft gears (4, Fig. 1) by pressing them off.Remove balancer shaft thrust plates (3, Fig. 1).Repair

Fig. 2-Balancer Shaft Journals and Bushings MeasurementCheck oil clearance between balancer shaft journals (2, Fig. 2) and bushings (1). Maximum allowable clearance is 0.0058 in. (0.147 mm). If clearance is greater than this replace the bushings. If oil clearance is still too large, the balancer shaft must be replaced.

Fig. 3-Bushing RemovalThe first two bushings can be replaced using JD-249 Tool, Fig. 3.To remove the third bushing the flywheel housing must be removed, see Group 0433. IMPORTANT: Be sure that hole in each bushing lines up with upper oil lead hole in cylinder block.Press all bushings in from the front of the engine until flush with bushing bore chamfer in block using JD249 Tool.Inspect balancer shaft gears for worn, cracked or broken teeth.Installing Drive Gear

It may be necessary to place thrust plate on the shaft before installing the gear on the shaft depending on the type of thrust plate used.

Fig. 4-Replacing Balancer Shaft GearPosition balancer shaft drive gear on front of balancer shaft so slot in gear lines up with special key, and timing mark on front of gear faces away from balancer shaft. Press on gear using JD-247 Holding Tool to support shaft as shown in Fig. 4. Press gear on shaft with thrust plate in position. Clearance between thrust plate and gear should be 0.002 to 0.010 in. (0.05 to 0.25 mm).Installation

Apply a light film of oil to balancer journals and bushings.Secure thrust plates to front plate with hardware and tighten with 35 lb-ft (47 Nm) (5 kg-m).

Fig. 5-Timing Balancer ShaftInstall balancer shafts in their respective bores. Time balancer shafts as shown in Fig. 5 using JD254 Timing Tool.With a dial indicator check balancer shaft for end play of no more than 0.010 in. (0.25 mm) or no less than 0.002 in. (0.05 mm).

Fig. 6-Installing Balancer Shaft WeightsInstall balancer shaft weights, if used, being sure weights are installed on the machine surfaces of the shaft. Run the balancer shaft bolts through the weights and then through the shafts as shown in Fig. 6. Tighten special nuts to 43 lb-ft (58 N m) (6 kg-m).Replace oil pump gear and lower idler gear if necessary.

Fig. 7-Installing Timing Gear CoverInstall timing gear cover and crankshaft pulley (Fig. 7).Install engine oil cooler coolant hose.Install fan, alternator and fan

Fig. 1-Engine Balancer ShaftsTwo types of balancer shafts are used (Fig. 1). They are mounted in the lower half of the cylinder block and each rotates in three pressure-lubricated replaceable bushings.The balancer shafts rotate in opposite directions to reduce engine vibration. Thrust of the balancer shafts is absorbed by thrust plates fastened to the front of the cylinder block.Removal

Remove fan belts, alternator, and fan.Remove oil pan.Disconnect oil cooler lines.Use a pulley puller to remove the crankshaft pulley.Remove the timing gear cover.Remove weights (2, Fig. 1), from the balancer shafts, if equipped.Remove oil pump gear and lower idler gear.Remove balancer shafts and identify as left and right.Remove balancer shaft gears (4, Fig. 1) by pressing them off.Remove balancer shaft thrust plates (3, Fig. 1).Repair

Fig. 2-Balancer Shaft Journals and Bushings MeasurementCheck oil clearance between balancer shaft journals (2, Fig. 2) and bushings (1). Maximum allowable clearance is 0.0058 in. (0.147 mm). If clearance is greater than this replace the bushings. If oil clearance is still too large, the balancer shaft must be replaced.

Fig. 3-Bushing RemovalThe first two bushings can be replaced using JD-249 Tool, Fig. 3.To remove the third bushing the flywheel housing must be removed, see Group 0433. IMPORTANT: Be sure that hole in each bushing lines up with upper oil lead hole in cylinder block.Press all bushings in from the front of the engine until flush with bushing bore chamfer in block using JD249 Tool.Inspect balancer shaft gears for worn, cracked or broken teeth.Installing Drive Gear

It may be necessary to place thrust plate on the shaft before installing the gear on the shaft depending on the type of thrust plate used.

Fig. 4-Replacing Balancer Shaft GearPosition balancer shaft drive gear on front of balancer shaft so slot in gear lines up with special key, and timing mark on front of gear faces away from balancer shaft. Press on gear using JD-247 Holding Tool to support shaft as shown in Fig. 4. Press gear on shaft with thrust plate in position. Clearance between thrust plate and gear should be 0.002 to 0.010 in. (0.05 to 0.25 mm).Installation

Apply a light film of oil to balancer journals and bushings.Secure thrust plates to front plate with hardware and tighten with 35 lb-ft (47 Nm) (5 kg-m).

Fig. 5-Timing Balancer ShaftInstall balancer shafts in their respective bores. Time balancer shafts as shown in Fig. 5 using JD254 Timing Tool.With a dial indicator check balancer shaft for end play of no more than 0.010 in. (0.25 mm) or no less than 0.002 in. (0.05 mm).

Fig. 6-Installing Balancer Shaft WeightsInstall balancer shaft weights, if used, being sure weights are installed on the machine surfaces of the shaft. Run the balancer shaft bolts through the weights and then through the shafts as shown in Fig. 6. Tighten special nuts to 43 lb-ft (58 N m) (6 kg-m).Replace oil pump gear and lower idler gear if necessary.

Fig. 7-Installing Timing Gear CoverInstall timing gear cover and crankshaft pulley (Fig. 7).Install engine oil cooler coolant hose.Install fan, alternator and fan

Have questions with 101482-4351?

Group cross 101482-4351 ZEXEL

Isuzu

101482-4351

9 400 611 687

8943811481

INJECTION-PUMP ASSEMBLY

4JB1

4JB1