Information injection-pump assembly

ZEXEL

101482-0390

1014820390

ISUZU

1156000471

1156000471

Rating:

Service parts 101482-0390 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

4.

SUPPLY PUMP

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

9-15300-184-2

12.

Open Pre:MPa(Kqf/cm2)

9.8{100}

15.

NOZZLE SET

Include in #1:

101482-0390

as INJECTION-PUMP ASSEMBLY

Include in #2:

104749-1180

as _

Cross reference number

ZEXEL

101482-0390

1014820390

ISUZU

1156000471

1156000471

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle holder

105031-2480

Opening pressure

MPa

9.8

Opening pressure

kgf/cm2

100

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.2

2.15

2.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

13.5

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

70

68.6

71.4

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

13.5

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

79

76.6

81.4

Max. variation between cylinders

%

0

-3

3

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.5

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

46.6

44.7

48.5

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

10.3+-0.

5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

17.5

15.2

19.8

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Test data Ex:

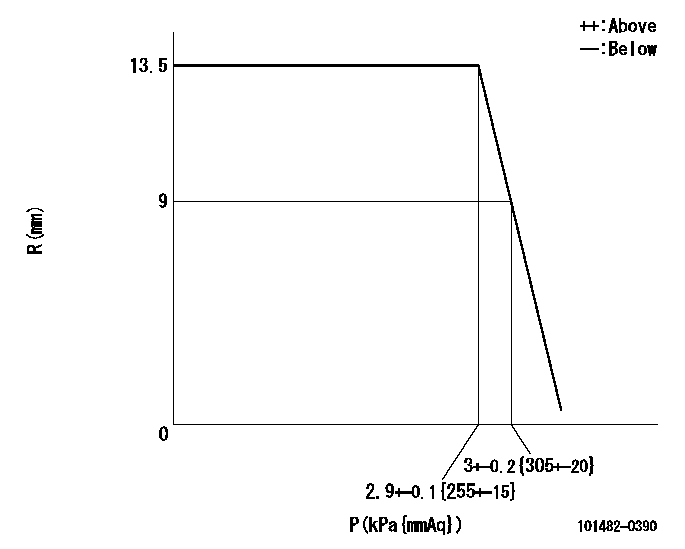

Governor adjustment

R:Rack position (mm)

P:Negative pressure

----------

----------

----------

----------

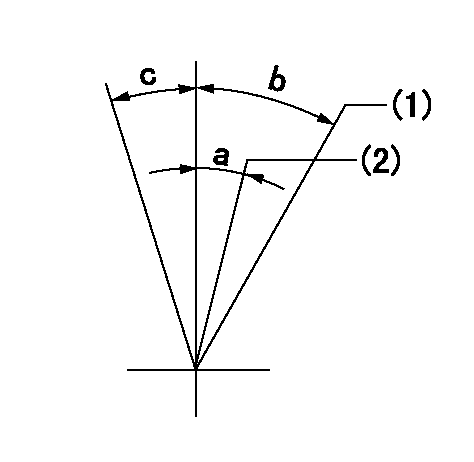

Speed control lever angle

(1)Rack position = aa

(2)Full position

----------

aa=17.5mm

----------

a=(8deg30min) b=14deg30min c=(11deg)

----------

aa=17.5mm

----------

a=(8deg30min) b=14deg30min c=(11deg)

Timing setting

(1)Pump vertical direction

(2)Position of pump side coupling's threaded hole at No. 1 cylinder's beginning of injection.

(3)-

(4)-

----------

----------

a=(10deg)

----------

----------

a=(10deg)

Information:

Installation procedure

Installation: Oil pan* Clean the sealant application surfaces of each part. * Apply a bead of sealant to each of the mating surfaces of the timing gear case, lower crankcase and front plate (at the two locations indicated the illustration). Installation: Oil pan* Clean the mating surfaces of each part. * Apply a bead of sealant to the mating surface of the oil pan evenly and without any breaks.* Mount the oil pan within three minutes of applying the sealant. Make sure that the sealant stays in place.

* Do not start the engine less than an hour after installation. If the oil pan mounting bolts were loosened or removed, be sure to reapply sealant.

Oil Pump

* Disassembly sequence1 Oil pump cover2 Driven gear3 Plug4 Relief valve spring5 Steel ball6 Gear and case7 O-ring*a Drive gear*b Oil pump gearP Locating pinX Non-reusable parts* Assembly sequenceFollow the disassembly procedure in reverse.Service standards (Unit: mm) Tightening torque (Unit: N m {kgf m}) Lubricant and/or sealant Inspection procedure

Inspection: Oil pump cover, driven gear, and gear and case* Measure the clearance between each gear's shaft and the oil pump cover, as well as between each gear's shaft and the gear and case. * If the measurements are not within the standard value range, replace the defective part(s). Inspection: Driven gear, drive gear and gear and case* Carry out the following inspection. Replace the oil pump if any defects are found. (1) Sinkage of each gear from gear and case end surface(2) Gear and case-to-tooth tip clearance for each gear Oil Cooler <Engine-Mounted Type, Engine Separately Mounted Type>, and Oil Filter <Engine-Mounted Type>

* Wipe up any spilled engine oil, as it can cause fires.* To avoid any risks of burns, take care not to touch the engine oil when the engine is hot.

* Make sure not to put any engine oil on the belt when working on the oil cooler and oil filter. Belt soiled with oil or grease may easily slip, resulting in deteriorated performance of the cooling system.* Do not reuse the oil filter elements by washing.

* Removal sequence1 Oil filter2 Plug3 Regulator valve spring4 Regulator valve5 Plug6 Bypass valve spring7 Bypass valve8 Oil cooler element9 Gasket10 Water drain plug11 Oil cooler body12 O-ring13 Gasket14 Water separate lipX Non-reusable parts* Installation sequenceFollow the removal sequence in reverse.Service standards (Unit: mm) Tightening torque (Unit: N m {kgf m}) Lubricant and/or sealant Special tools Removal procedure

Removal: Oil filter <Engine-mounted type> Inspection procedure

Inspection: Oil cooler element* Plug the outlet of the oil cooler element and connect a hose to the engine oil inlet port. Then, immerse the oil cooler element in a tank of water. * Apply an air pressure of 1.5 MPa {15 kgf/cm2} for 15 seconds through the hose, and check for any air leaks.* Replace the element if it leaks air.Installation procedure

Installation: Oil cooler <Engine-mounted type>* Clean the oil filter mounting surface of the oil cooler. * Apply a thin coat of engine oil on the oil filter gasket.* Screw in the

Installation: Oil pan* Clean the sealant application surfaces of each part. * Apply a bead of sealant to each of the mating surfaces of the timing gear case, lower crankcase and front plate (at the two locations indicated the illustration). Installation: Oil pan* Clean the mating surfaces of each part. * Apply a bead of sealant to the mating surface of the oil pan evenly and without any breaks.* Mount the oil pan within three minutes of applying the sealant. Make sure that the sealant stays in place.

* Do not start the engine less than an hour after installation. If the oil pan mounting bolts were loosened or removed, be sure to reapply sealant.

Oil Pump

* Disassembly sequence1 Oil pump cover2 Driven gear3 Plug4 Relief valve spring5 Steel ball6 Gear and case7 O-ring*a Drive gear*b Oil pump gearP Locating pinX Non-reusable parts* Assembly sequenceFollow the disassembly procedure in reverse.Service standards (Unit: mm) Tightening torque (Unit: N m {kgf m}) Lubricant and/or sealant Inspection procedure

Inspection: Oil pump cover, driven gear, and gear and case* Measure the clearance between each gear's shaft and the oil pump cover, as well as between each gear's shaft and the gear and case. * If the measurements are not within the standard value range, replace the defective part(s). Inspection: Driven gear, drive gear and gear and case* Carry out the following inspection. Replace the oil pump if any defects are found. (1) Sinkage of each gear from gear and case end surface(2) Gear and case-to-tooth tip clearance for each gear Oil Cooler <Engine-Mounted Type, Engine Separately Mounted Type>, and Oil Filter <Engine-Mounted Type>

* Wipe up any spilled engine oil, as it can cause fires.* To avoid any risks of burns, take care not to touch the engine oil when the engine is hot.

* Make sure not to put any engine oil on the belt when working on the oil cooler and oil filter. Belt soiled with oil or grease may easily slip, resulting in deteriorated performance of the cooling system.* Do not reuse the oil filter elements by washing.

* Removal sequence1 Oil filter2 Plug3 Regulator valve spring4 Regulator valve5 Plug6 Bypass valve spring7 Bypass valve8 Oil cooler element9 Gasket10 Water drain plug11 Oil cooler body12 O-ring13 Gasket14 Water separate lipX Non-reusable parts* Installation sequenceFollow the removal sequence in reverse.Service standards (Unit: mm) Tightening torque (Unit: N m {kgf m}) Lubricant and/or sealant Special tools Removal procedure

Removal: Oil filter <Engine-mounted type> Inspection procedure

Inspection: Oil cooler element* Plug the outlet of the oil cooler element and connect a hose to the engine oil inlet port. Then, immerse the oil cooler element in a tank of water. * Apply an air pressure of 1.5 MPa {15 kgf/cm2} for 15 seconds through the hose, and check for any air leaks.* Replace the element if it leaks air.Installation procedure

Installation: Oil cooler <Engine-mounted type>* Clean the oil filter mounting surface of the oil cooler. * Apply a thin coat of engine oil on the oil filter gasket.* Screw in the