Information injection-pump assembly

BOSCH

9 400 614 206

9400614206

ZEXEL

101481-9110

1014819110

NISSAN-DIESEL

1671290113

1671290113

Rating:

Service parts 101481-9110 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-T9300

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 206

9400614206

ZEXEL

101481-9110

1014819110

NISSAN-DIESEL

1671290113

1671290113

Zexel num

Bosch num

Firm num

Name

101481-9110

9 400 614 206

1671290113 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FD33T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

FD33T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.8

2.75

2.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.2

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

67.4

66.3

68.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.8

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

58.2

56.2

60.2

Max. variation between cylinders

%

0

-2.5

2.5

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

-

Rack position

8+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

10

8

12

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_04

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

81

71

91

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1350--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1300

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1600

Advance angle

deg.

1.8

1.3

2.3

Timer adjustment_04

Pump speed

r/min

1800

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

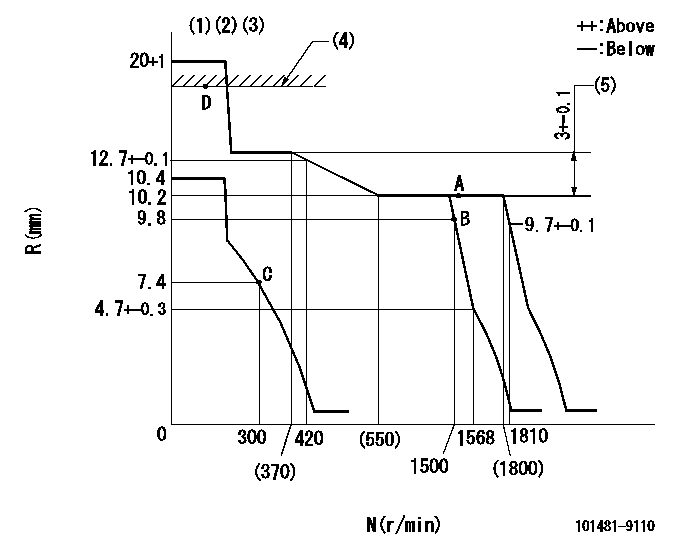

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Confirm that the idle sub-spring does not operate at high idle.

(4)RACK LIMIT

(5)Rack difference between N = N1 and N = N2

----------

K=10 N1=1500r/min N2=300r/min

----------

----------

K=10 N1=1500r/min N2=300r/min

----------

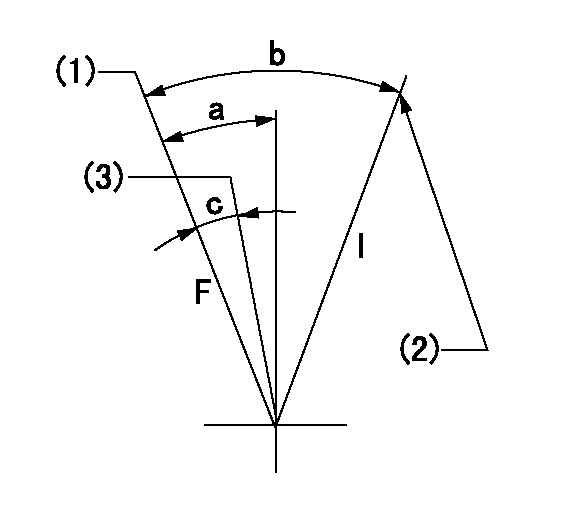

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)Stopper bolt setting

(3)Set the pump speed at bb.

----------

aa=1810r/min bb=1500r/min

----------

a=21deg+-5deg b=32deg+-5deg c=9deg+-5deg

----------

aa=1810r/min bb=1500r/min

----------

a=21deg+-5deg b=32deg+-5deg c=9deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=10.5deg+-5deg b=53deg+-5deg

----------

----------

a=10.5deg+-5deg b=53deg+-5deg

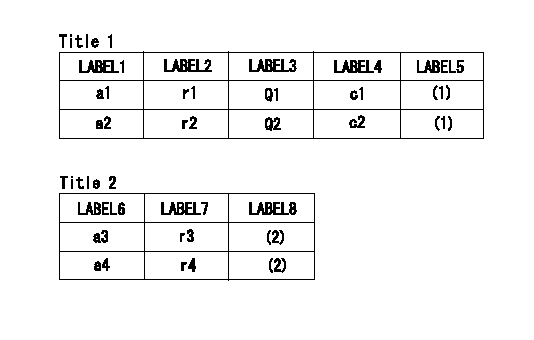

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)-

----------

----------

a1=B a2=- r1=1500r/min r2=- Q1=67.4+-1.1mm3/st Q2=- c1=+-2.5% c2=- a3=36 a4=30 r3=1800r/min r4=1500r/min

----------

----------

a1=B a2=- r1=1500r/min r2=- Q1=67.4+-1.1mm3/st Q2=- c1=+-2.5% c2=- a3=36 a4=30 r3=1800r/min r4=1500r/min

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection (position of gear's 'M' mark)

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(60deg)

----------

aa=14deg

----------

a=(60deg)

Information:

Literature Information

This manual should be stored in the literature storage area.The information contained in this document is the most current information available for coolants, fuels, and lubricants. Refer to the Operation and Maintenance Manual for any special lubrication requirements for your engine.Whenever a question arises regarding the engine, this publication, or the Operation and Maintenance Manual, please consult any Cat dealer for the latest available information.Safety

Refer to the Operation and Maintenance Manual for your engine for all safety information. Read and understand the basic safety precautions listed in the Safety Section. In addition to safety precautions, this section identifies the text and locations of safety signs used on the engine.Read and understand the basic precautions listed in the Safety Section before operating or performing lubrication, maintenance and repair on this engine.Maintenance

Refer to the Operation and Maintenance Manual for your engine to determine all maintenance requirements.Maintenance Intervals

Use the Maintenance Interval Schedule in the Operation and Maintenance Manual for your engine to determine servicing intervals. The actual operating environment of the engine also governs the maintenance interval schedule. Therefore, under extremely severe, dusty, wet or freezing cold operating conditions, more frequent lubrication and maintenance than is specified in the Maintenance Interval Schedule may be necessary.Extended Engine Oil Drains and Warranty

Failures that result from extended oil drain periods are not Caterpillar factory defects and therefore are not covered by Caterpillar's warranty. In addition, failures that result from not using the recommended oil type are not Caterpillar factory defects and therefore are not covered by Caterpillar's warranty.Refer to the applicable Operation and Maintenance Manual for standard oil drain periods and to the Maintenance Section, "Lubricant Specifications" of this publication for engine oil type and viscosity grade recommendations.To reduce the potential risk of failures associated with extended oil drain periods; it is recommended that oil drain intervals only be extended based on oil analysis, and subsequent engine inspections. Oil analysis alone does not provide an indication of the rate of formation of lacquer, varnish and/or carbon on pistons and other engine surfaces. The only accurate way to evaluate specific oil performance in a specific engine and application that utilizes extended oil drain periods is to observe the effects on the engine components. This involves tear-down inspections of engines that have run to their normal overhaul period with extended oil drain intervals. Following this recommendation will help ensure that excessive component wear does not take place in a given application.

Light loads, low hour accumulation, and excessive idling time can contribute to excessive water in the crankcase oil. Corrosive damage, piston deposits and increased oil consumption can also result. If oil analysis is not done or the results are ignored, the potential for corrosive damage and piston deposits increases. Refer to the appropriate Operation and Maintenance Manual for guidance.

Note: Failures that result from extended oil drain periods are not warrantable failures, regardless of use of this recommended procedure. Failures that result from extended engine oil drain periods are considered improper use under the warranty.Aftermarket Products

This manual should be stored in the literature storage area.The information contained in this document is the most current information available for coolants, fuels, and lubricants. Refer to the Operation and Maintenance Manual for any special lubrication requirements for your engine.Whenever a question arises regarding the engine, this publication, or the Operation and Maintenance Manual, please consult any Cat dealer for the latest available information.Safety

Refer to the Operation and Maintenance Manual for your engine for all safety information. Read and understand the basic safety precautions listed in the Safety Section. In addition to safety precautions, this section identifies the text and locations of safety signs used on the engine.Read and understand the basic precautions listed in the Safety Section before operating or performing lubrication, maintenance and repair on this engine.Maintenance

Refer to the Operation and Maintenance Manual for your engine to determine all maintenance requirements.Maintenance Intervals

Use the Maintenance Interval Schedule in the Operation and Maintenance Manual for your engine to determine servicing intervals. The actual operating environment of the engine also governs the maintenance interval schedule. Therefore, under extremely severe, dusty, wet or freezing cold operating conditions, more frequent lubrication and maintenance than is specified in the Maintenance Interval Schedule may be necessary.Extended Engine Oil Drains and Warranty

Failures that result from extended oil drain periods are not Caterpillar factory defects and therefore are not covered by Caterpillar's warranty. In addition, failures that result from not using the recommended oil type are not Caterpillar factory defects and therefore are not covered by Caterpillar's warranty.Refer to the applicable Operation and Maintenance Manual for standard oil drain periods and to the Maintenance Section, "Lubricant Specifications" of this publication for engine oil type and viscosity grade recommendations.To reduce the potential risk of failures associated with extended oil drain periods; it is recommended that oil drain intervals only be extended based on oil analysis, and subsequent engine inspections. Oil analysis alone does not provide an indication of the rate of formation of lacquer, varnish and/or carbon on pistons and other engine surfaces. The only accurate way to evaluate specific oil performance in a specific engine and application that utilizes extended oil drain periods is to observe the effects on the engine components. This involves tear-down inspections of engines that have run to their normal overhaul period with extended oil drain intervals. Following this recommendation will help ensure that excessive component wear does not take place in a given application.

Light loads, low hour accumulation, and excessive idling time can contribute to excessive water in the crankcase oil. Corrosive damage, piston deposits and increased oil consumption can also result. If oil analysis is not done or the results are ignored, the potential for corrosive damage and piston deposits increases. Refer to the appropriate Operation and Maintenance Manual for guidance.

Note: Failures that result from extended oil drain periods are not warrantable failures, regardless of use of this recommended procedure. Failures that result from extended engine oil drain periods are considered improper use under the warranty.Aftermarket Products

Have questions with 101481-9110?

Group cross 101481-9110 ZEXEL

Nissan-Diesel

101481-9110

9 400 614 206

1671290113

INJECTION-PUMP ASSEMBLY

FD33T

FD33T