Information injection-pump assembly

BOSCH

9 400 614 193

9400614193

ZEXEL

101472-0112

1014720112

ISUZU

8970752912

8970752912

Rating:

Service parts 101472-0112 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

11.8(120)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 193

9400614193

ZEXEL

101472-0112

1014720112

ISUZU

8970752912

8970752912

Zexel num

Bosch num

Firm num

Name

101472-0112

9 400 614 193

8970752912 ISUZU

INJECTION-PUMP ASSEMBLY

C240 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

C240 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-2

Pre-stroke

mm

2.25

2.2

2.3

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

34.6

33.6

35.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.4

Pump speed

r/min

725

725

725

Average injection quantity

mm3/st.

40.6

39.1

42.1

Max. variation between cylinders

%

0

-4.5

4.5

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

-

Rack position

8.9+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8

6.9

9.1

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_04

Adjusting point

D

Rack position

(13.1)+-

0.1

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

70

80

Fixing the lever

*

Rack limit

*

Test data Ex:

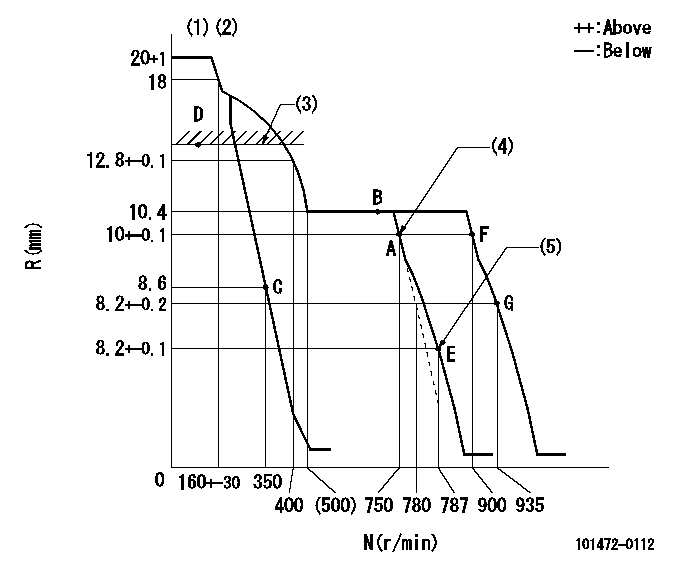

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT: RAL

(4)Main spring setting

(5)Set idle sub-spring

----------

K=16 RAL=(13.1)+-0.1mm

----------

----------

K=16 RAL=(13.1)+-0.1mm

----------

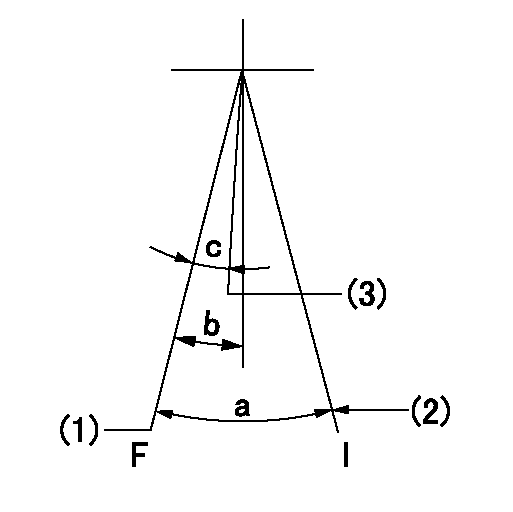

Speed control lever angle

F:Full speed

I:Idle

(1)Speed = aa (set at delivery)

(2)Stopper bolt setting

(3)Set the pump speed at bb.

----------

aa=900r/min bb=750r/min

----------

a=19deg+-5deg b=6deg+-5deg c=5deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=19deg+-5deg b=6deg+-5deg c=5deg+-5deg

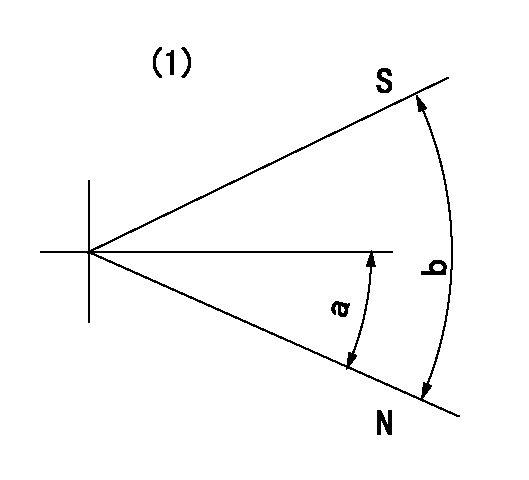

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

----------

----------

a=36.5deg+-5deg b=53deg+-5deg

----------

----------

a=36.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Gear mark Z for the No. 4 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(60deg)

----------

aa=16deg

----------

a=(60deg)

Information:

Reference for 3500 Series Engines

Troubleshooting, M0080819, "3516E Engine for Tier 4 Final 994K Wheel Loaders".Testing and Adjusting, M0080815, "3516E Engine for Tier 4 Final 994K Wheel Loaders".Disassembly and Assembly, M0092351, "3516E Engines for Caterpillar Built Machines".Procedure

Note: If failed parts need to be shipped back, please cap off the ports using the caps from the new part.

What code are you troubleshooting? ____________________

Follow the correct troubleshooting procedure. Refer to "Reference for C175 Engines" and "Reference for 3500 Series Engines" Sections for correct media number to use.

When troubleshooting procedure requests the DEF quality check, DEF system inspection filter replacement or dosing accuracy, document those results in Table 1, Table 2, Table 3, and Table 4.

Table 1

DEF Quality Results

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test (include photo of test strip is possible) Pass/Fail

3 DEF concentration Test % at 20° C (68° F)

Table 2

DEF Tank Vent Line, Breather, and Cap Inspection Results

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test (include photo of test strip is possible)

3 DEF concentration Test

4 Remove the breather and inspect at the breather-to-vent line connections if debris is bypassing the breather (take photo)

5 Inspect the DEF tank manual fill cap for damage or debris (take photo)

6 Remove the DEF tank manual fill cap and inspect for damage or debris at the manual fill inlet to the tank (take a photo)

7 Remove the fill neck strainer and inspect for damage or debris (take a photo)

8 Clean or replace the strainer (if necessary) (take a photo)

Table 3

DEF Pump Filters Replaced

Step Instruction Completed (Yes/No) Result Comments Units

1 Prior to removal, inspect the DEF pump suction line fitting and DEF pump filter cap for any damage (take a photo)

2 Replace the DEF pump suction line filter fitting and DEF pump filter on the affected DEF pump. Comment on any notable damage or debris (take a photo of each post removal)

3 Bag, label (pump number in PETU, pump serial number, date removed), and return with pump.

Table 4

Dosing Accuracy Test

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting, Aftertreatment SCR system Dosing Test.

2 For the pump in question, take a photograph of both DEF injectors, mounts, gaskets, bolts on the SCR inlet prior to removal. Ensure that the picture captures the DEF injector serial number and part number and not which position and which aftertreatment it was installed.

3 For the pump in question, remove both injectors from the SCR inlet.

4 Take a photograph of both DEF injector mounts on the SCR inlet and the tip of both DEF injectors.

5 Install each injector on the beaker.

6 Run the DEF System Dosing Accuracy test through Cat® ET for each injector.

7 Use the beaker to measure the amount of fluid from the dosing test for each injector. ____________________ml

____________________ml

8 Repeat the test for each injector to verify consistency.

Troubleshooting, M0080819, "3516E Engine for Tier 4 Final 994K Wheel Loaders".Testing and Adjusting, M0080815, "3516E Engine for Tier 4 Final 994K Wheel Loaders".Disassembly and Assembly, M0092351, "3516E Engines for Caterpillar Built Machines".Procedure

Note: If failed parts need to be shipped back, please cap off the ports using the caps from the new part.

What code are you troubleshooting? ____________________

Follow the correct troubleshooting procedure. Refer to "Reference for C175 Engines" and "Reference for 3500 Series Engines" Sections for correct media number to use.

When troubleshooting procedure requests the DEF quality check, DEF system inspection filter replacement or dosing accuracy, document those results in Table 1, Table 2, Table 3, and Table 4.

Table 1

DEF Quality Results

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test (include photo of test strip is possible) Pass/Fail

3 DEF concentration Test % at 20° C (68° F)

Table 2

DEF Tank Vent Line, Breather, and Cap Inspection Results

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test (include photo of test strip is possible)

3 DEF concentration Test

4 Remove the breather and inspect at the breather-to-vent line connections if debris is bypassing the breather (take photo)

5 Inspect the DEF tank manual fill cap for damage or debris (take photo)

6 Remove the DEF tank manual fill cap and inspect for damage or debris at the manual fill inlet to the tank (take a photo)

7 Remove the fill neck strainer and inspect for damage or debris (take a photo)

8 Clean or replace the strainer (if necessary) (take a photo)

Table 3

DEF Pump Filters Replaced

Step Instruction Completed (Yes/No) Result Comments Units

1 Prior to removal, inspect the DEF pump suction line fitting and DEF pump filter cap for any damage (take a photo)

2 Replace the DEF pump suction line filter fitting and DEF pump filter on the affected DEF pump. Comment on any notable damage or debris (take a photo of each post removal)

3 Bag, label (pump number in PETU, pump serial number, date removed), and return with pump.

Table 4

Dosing Accuracy Test

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting, Aftertreatment SCR system Dosing Test.

2 For the pump in question, take a photograph of both DEF injectors, mounts, gaskets, bolts on the SCR inlet prior to removal. Ensure that the picture captures the DEF injector serial number and part number and not which position and which aftertreatment it was installed.

3 For the pump in question, remove both injectors from the SCR inlet.

4 Take a photograph of both DEF injector mounts on the SCR inlet and the tip of both DEF injectors.

5 Install each injector on the beaker.

6 Run the DEF System Dosing Accuracy test through Cat® ET for each injector.

7 Use the beaker to measure the amount of fluid from the dosing test for each injector. ____________________ml

____________________ml

8 Repeat the test for each injector to verify consistency.

Have questions with 101472-0112?

Group cross 101472-0112 ZEXEL

Isuzu

101472-0112

9 400 614 193

8970752912

INJECTION-PUMP ASSEMBLY

C240

C240