Information injection-pump assembly

ZEXEL

101471-0110

1014710110

ISUZU

5156003152

5156003152

Rating:

Service parts 101471-0110 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-024-1

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Cross reference number

ZEXEL

101471-0110

1014710110

ISUZU

5156003152

5156003152

Zexel num

Bosch num

Firm num

Name

101471-0110

5156003152 ISUZU

INJECTION-PUMP ASSEMBLY

C330 * K

C330 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle

105000-1650

Bosch type code

DN0SD2110

Nozzle holder

105091-1090

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.2

2.15

2.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

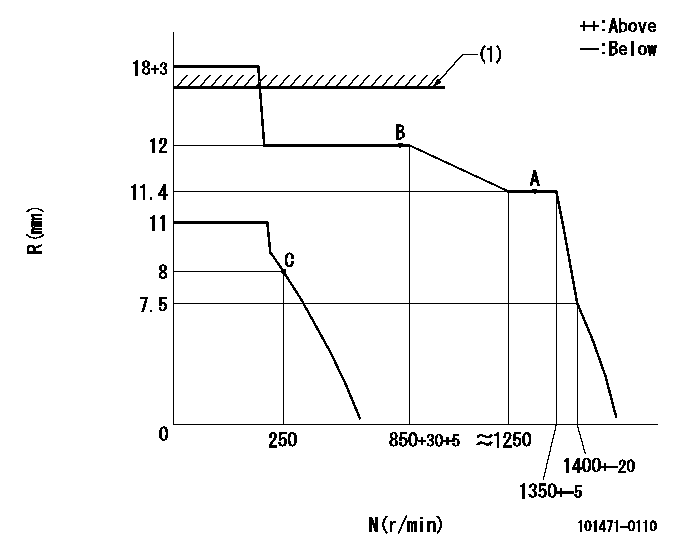

Injection quantity adjustment

Adjusting point

A

Rack position

11.4

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

60.8

59.8

61.8

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

12

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

61.2

58.7

63.7

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

8.5

7.5

9.5

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

95

95

Fixing the lever

*

Remarks

Excess fuel for starting.

Excess fuel for starting.

Timer adjustment

Pump speed

r/min

500+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.7

0.2

1.2

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

1.9

1.1

2.6

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

3.9

3.4

4.4

Timer adjustment_05

Pump speed

r/min

1750

Advance angle

deg.

6

5.2

6.2

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)At rack cap installation: R1

----------

R1=(17.5)mm

----------

----------

R1=(17.5)mm

----------

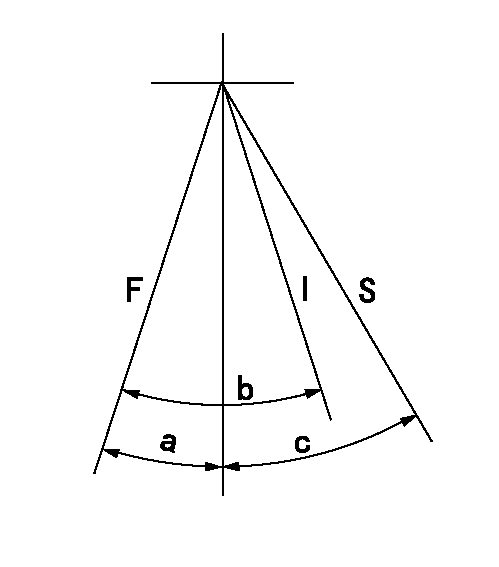

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=18.5deg+-5deg b=32.5deg+-5deg c=32deg+-3deg

----------

----------

a=18.5deg+-5deg b=32.5deg+-5deg c=32deg+-3deg

Information:

Table 4

Ethylene Glycol Concentration

Concentration Freeze Protection Boil Protection(1)

20 Percent −8° C (18° F) 102° C (216° F)

50 Percent −37 °C (−34 °F) 106 °C (223 °F)

60 Percent −52 °C (−62 °F) 111 °C (232 °F)

(1) Boiling protection is increased with the use of a pressurized radiator.Do not use propylene glycol in concentrations that exceed 50 percent glycol because of the reduced heat transfer capability. Use ethylene glycol in conditions that require additional protection against boiling or freezing. Do not use ethylene glycol in concentrations that exceed 60 percent glycol.

Table 5

Propylene Glycol Concentration

Concentration Freeze Protection Boil Protection(1)

50 Percent −32 °C (−26 °F) 106 °C (223 °F)

(1) Boiling protection is increased with the use of a pressurized radiator.Propylene glycol coolant that is used in the cooling systems for Cat diesel engines must meet ASTM D6210-06, "Fully-Formulated Glycol-Based Engine Coolant for Heavy-Duty Engines". When propylene glycol coolant is used in heavy-duty diesel engines, a regular addition of SCA is required for protection against liner cavitation. Consult your Cat dealer for additional information.Ethylene or propylene glycols used in cooling systems for Cat diesel engines must meet ASTM E1177-06, "Standard Specification for Engine Coolant Grade Glycol".Testing the Concentration of Glycol

To check the concentration of glycol, use the 245-5829 Coolant/Battery Tester/Refractometer or 360-0774 refractometer. The tester can be used with ethylene or propylene glycol.

Illustration 1 g01189253

Approximate curve of the freezing point for a typical ethylene glycol solution.

Table 6

Freeze Protection for Antifreeze Concentrations(1)

Protection to: Concentration

−8° C (18° F) 20% glycol

80% water

−15 °C (5 °F) 30% glycol

70% water

−24 °C (−12 °F) 40% glycol

60% water

−37 °C (−34 °F) 50% glycol

50% water

−52 °C (−62 °F) 60% glycol

40% water

(1) Ethylene glycol-based antifreeze.Alternative products that are used to protect from boiling or freezing of the engine coolant include:

“1,3 propandiol” (PDO)

glycerin

mixtures of these alternative products with glycolAt the time of publication of this document, there currently exists no ASTM, "specifications" for coolants using these chemicals. Until specifications are published and then evaluated by Cat, use of PDO and glycerin or glycerin/glycol coolants are not recommended in Cat cooling systems.Embitterment

Ethylene glycol is a toxic chemical with a naturally sweet taste. In order to avoid accidental excessive ingestion by humans or animals, coolants may contain embittering agents that make the coolant taste bad. All Cat glycol containing coolants (Cat ELC, Cat DEAC, and Cat NGEC) are embittered. Embittering agents have no beneficial or detrimental effect on coolant performance or characteristics.Coolant Terminology

Extended Life Coolant (ELC) - A coolant that relies largely on organic inhibitors for corrosion and cavitation protection. Carboxylate is an example of organic corrosion and cavitation inhibitors. Cat ELC and Cat ELI in water are extended life coolants that also include nitrites and molybdates for increased cavitation protection.

Commercial extended life coolants containing silicate do not meet the additional requirements set in this Special Publication for coolants claiming to meet Cat EC-1 specification.

Do not use commercial extended life coolants with more than 125 ppm silicon (present in the coolant in the form of silicate)

Extended life coolants that meet

Have questions with 101471-0110?

Group cross 101471-0110 ZEXEL

Isuzu

101471-0110

5156003152

INJECTION-PUMP ASSEMBLY

C330

C330