Information injection-pump assembly

ZEXEL

101461-0150

1014610150

ISUZU

5156008702

5156008702

Rating:

Service parts 101461-0150 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-097-0

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Cross reference number

ZEXEL

101461-0150

1014610150

ISUZU

5156008702

5156008702

Zexel num

Bosch num

Firm num

Name

101461-0150

5156008702 ISUZU

INJECTION-PUMP ASSEMBLY

4BA1 * K 14BC PE4A,5A, PE

4BA1 * K 14BC PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

1.95

1.9

2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

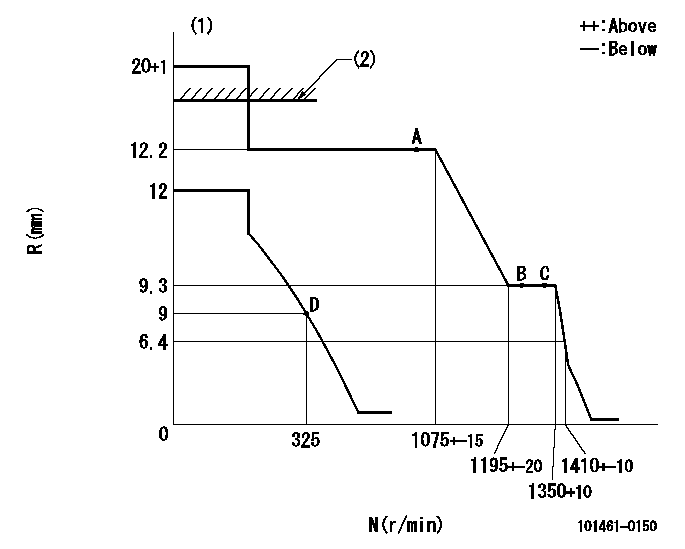

Injection quantity adjustment

Adjusting point

A

Rack position

12.2

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

46.3

44.8

47.8

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

9.3

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

29

27

31

Max. variation between cylinders

%

0

-6

6

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

13.6

12.2

15

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_04

Adjusting point

B

Rack position

9.3

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

29

26

32

Max. variation between cylinders

%

0

-6

6

Fixing the lever

*

Timer adjustment

Pump speed

r/min

500+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.7

0.2

1.2

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

1.5

1

2

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

6

6

6

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK CAP: R1

----------

K=15 R1=(17.5)mm

----------

----------

K=15 R1=(17.5)mm

----------

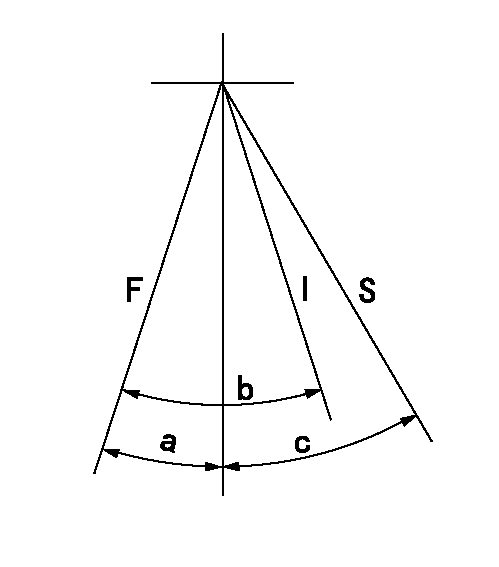

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=14deg+-5deg b=27deg+-5deg c=32deg+-3deg

----------

----------

a=14deg+-5deg b=27deg+-5deg c=32deg+-3deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(100deg)

----------

----------

a=(100deg)

Information:

Do not operate the machine if any guards or covers are missing or inadequately secured. Personnel could be seriously injured or machine damage may occur.

Observe the safe working load limits of all lifting and blocking devices and keep a safe distance from suspended/blocked loads. Personnel may be seriously injured or killed by falling loads.

Reference Section

Refer to Service Magazine, M0082326, "Diesel Exhaust Fluid (DEF) Contamination on C4.4 Machine Engines".Refer to Service Magazine, M0096547, "Diesel Exhaust Fluid (DEF) Pump Filter Maintenance on Certain C4.4 Machine Engines".Refer to Special Instruction, M0096185, "Diesel Exhaust Fluid (DEF) Pump Diesel Contamination Test on Certain C4.4 Engines".Problem

There have been instances of returned DEF pumps that have no fault found or indicating contamination.Resolution

Complete the form below and attach to any SIMSi claim in addition to a Product Status Report (PSR) from before any troubleshooting was performed or any diagnostic codes were cleared.

Use the electronic service tool to download a PSR with Histograms.

Enter the diagnostic codes that require troubleshooting: ___

Perform the correct troubleshooting procedure for any active diagnostic codes. Refer to Troubleshooting, Diagnostic Trouble Codes.

If the troubleshooting procedure requests that the DEF is tested for contamination or concentration , record the results in Table 1 and Table 2.

For other DEF-related troubleshooting procedures, follow the applicable troubleshooting steps and record the results in Table 3.

Table 1

DEF Contamination

Step Instruction Completed Result Units

1 Perform the test procedure for DEF contamination. Refer to Systems Operation, Testing and Adjusting, Diesel Exhaust Fluid Quality - Test.

2 Compensator measurements. Refer to Special Instruction, M0096185, "Diesel Exhaust Fluid (DEF) Pump Diesel Contamination Test on Certain C4.4 Engines".

Diameter (A) mm

Length (B) mm

3 If contamination is present, confirm that DEF system has been flushed. Refer to Systems Operation, Testing and Adjusting, Diesel Exhaust Fluid Tank - Flush

Table 2

DEF Concentration

Step Instruction Completed Result Units

1 Perform the test procedure for DEF concentration. Refer to Systems Operation, Testing and Adjusting, Diesel Exhaust Fluid Quality - Test. %

2 If the DEF concentration is out of specification, confirm that the DEF tank has been drained and filled with the correct specification of DEF. Refer to Operation and Maintenance Manual, Diesel Exhaust Fluid - Fill.

Table 3

DEF Troubleshooting

Step Instruction Completed Result Units

1 Latest engine and Dosing Control Unit (DCU) software has been installed. Refer to Troubleshooting, ECM Software - Install.

2 DEF lines have been checked for restrictions.

3 DEF pump has been checked for restrictions.

4 DEF injector has been checked for restrictions.

5 DEF lines have been inspected for leaks.

6 Confirm the DEF pressure. Refer to Troubleshooting, DEF Pressure Does Not Respond. kPa

7 DEF dosing system accuracy test has been performed. Refer to Troubleshooting, Aftertreatment SCR System Dosing - Test.

8 DEF pump filter replaced.

9 "Aftertreatment System Functional Test" performed. Refer to Troubleshooting, Service Tool Features.

Have questions with 101461-0150?

Group cross 101461-0150 ZEXEL

Isuzu

101461-0150

5156008702

INJECTION-PUMP ASSEMBLY

4BA1

4BA1