Information injection-pump assembly

ZEXEL

101452-9150

1014529150

YANMAR

12173751011

12173751011

Rating:

Service parts 101452-9150 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

ZEXEL

101452-9150

1014529150

YANMAR

12173751011

12173751011

Zexel num

Bosch num

Firm num

Name

101452-9150

12173751011 YANMAR

INJECTION-PUMP ASSEMBLY

4T90 * K

4T90 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

1.95

1.9

2

Rack position

R=R2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

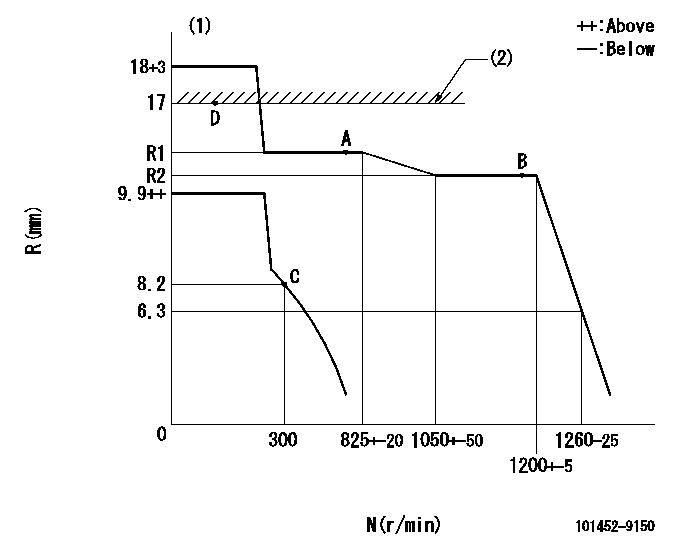

Injection quantity adjustment

Adjusting point

A

Rack position

R1

Pump speed

r/min

800

800

800

Each cylinder's injection qty

mm3/st.

38

36.5

39.5

Fixing the rack

*

Remarks

Measure rack position.

Measure rack position.

Injection quantity adjustment_02

Adjusting point

B

Rack position

R2

Pump speed

r/min

1200

1200

1200

Each cylinder's injection qty

mm3/st.

33.5

32.5

34.5

Basic

*

Fixing the rack

*

Remarks

Measure rack position.

Measure rack position.

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.2

Pump speed

r/min

300

300

300

Each cylinder's injection qty

mm3/st.

10

9

11

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

17

Pump speed

r/min

100

100

100

Each cylinder's injection qty

mm3/st.

55

55

60

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

----------

K=5

----------

----------

K=5

----------

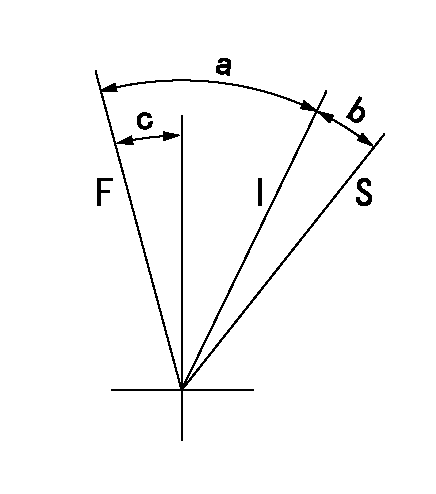

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=31.5deg+-5deg b=9deg+-3deg c=10deg+-5deg

----------

----------

a=31.5deg+-5deg b=9deg+-3deg c=10deg+-5deg

Information:

Illustration 2 g01681836

(3) CGI flex pipe

Inspect the CGI flex pipe that is installed on all Kenworth and Peterbilt chassis. Check for a previous update to the CGI flex pipe under either a Peterbilt or Kenworth Technical Information BulletinThis work should be charged to your local OEM dealer with instructions that are provided with the service letter.

Peterbilt -Field Repair Notice 408-1 or newer Clean Gas Induction (CGI) and Main Exhaust Pipe Couplings

Kenworth – Technical Information Bulletin Number 43-12 or newer

Drain and save the coolant. The saved coolant can then be reused. Draining the coolant is necessary in order to replace the ARD combustion head.

Illustration 3 g01678253

(4) CGI coolant hose and clamps that are replaced on S/N:SDP1-17026

Inspect the CGI coolant hose and clamps and replace the CGI coolant hose and clamps if it is necessary on S/N:SDP1-17026.

Only replace the hose if the hose has not already been updated. Only black colored hoses should be replaced. The replacement hose is blue or green in color. The blue or green hose does not need to be replaced.Note: There will be some coolant that is left in the line after draining.

Illustration 4 g01678273

(5) Location of fuel control valves

Replace the Pilot and Main Fuel Control Valves. The fuel control valve must not be overtorqued.Torque for the two solenoid valve groups ... 50 5 N m (37 4 lb ft)Final installation torque for the two solenoid nuts ... 20 3 N m (15 2 lb ft)

Replace the ARD combustion head and the components of the ARD utilizing the Disassembly and Assembly Manual, RENR9706 for the proper procedure.Note: Do not install the fuel lines to the ARD Combustion head at this time. These lines will be installed after flushing the fuel system. Leave the protective shipping caps in the fuel ports of the ARD combustion head.

Illustration 5 g01681795

(8) ARD flame detection temperature sensor

In addition to the replacement of the ARD combustion head, install a new ARD flame detection temperature sensor. Refer to Special Instruction, REHS3794 for proper wire routing. If a stainless steel zip tie is removed a newstainless steel zip tie should be used.

Illustration 6 g01681813

(9) CGI temperature sensor

Replace the CGI temperature sensor. Refer to the Disassembly and Assembly Manual, RENR9706 and Disassembly and Assembly Manual, RENR9705 for the proper procedures. Proper wire routing should be followed. If a stainless steel zip tie is removed a new stainless steel zip tie should be used.

Refill the cooling system with the coolant that was saved in Step 8.

Flush the ARD fuel system. Refer to Special Instruction, REHS3848 for the correct procedure.

Flash the engine with the latest software. The release date of the software must be November 2008 or a newer date.Tables that are used in order to look up software and the process for obtaining the software are provided below.

Perform a verification test of the air system and save the file.Note: Refer to Troubleshooting Guide, RENR9343, "Air System Verification Test" that is located on the Service Information System for the pass or fail criteria.

Perform a stationary regeneration. Check

Have questions with 101452-9150?

Group cross 101452-9150 ZEXEL

Yanmar

101452-9150

12173751011

INJECTION-PUMP ASSEMBLY

4T90

4T90