Information injection-pump assembly

BOSCH

9 400 614 182

9400614182

ZEXEL

101452-3123

1014523123

KOMATSU

6204721422

6204721422

Rating:

Service parts 101452-3123 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6202-12-3100

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 182

9400614182

ZEXEL

101452-3123

1014523123

KOMATSU

6204721422

6204721422

Zexel num

Bosch num

Firm num

Name

101452-3123

9 400 614 182

6204721422 KOMATSU

INJECTION-PUMP ASSEMBLY

4D95L K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4D95L K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEF967d}

1404 Test oil ISO4113 or {SAEF967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-4-3

Pre-stroke

mm

1.5

1.45

1.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 90 89.5 90.5

Cyl.1-2 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cal 1-3 deg. 270 269.5 270.5

Cal 1-3 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

12

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

45.8

44.8

46.8

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.3+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

11

10

12

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

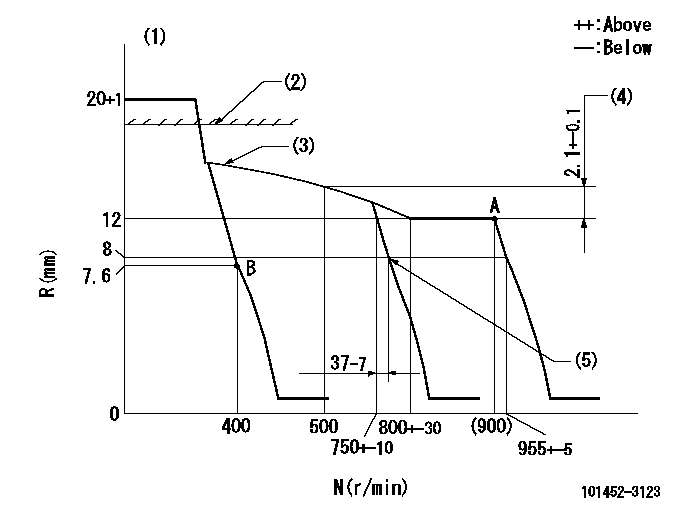

Governor adjustment

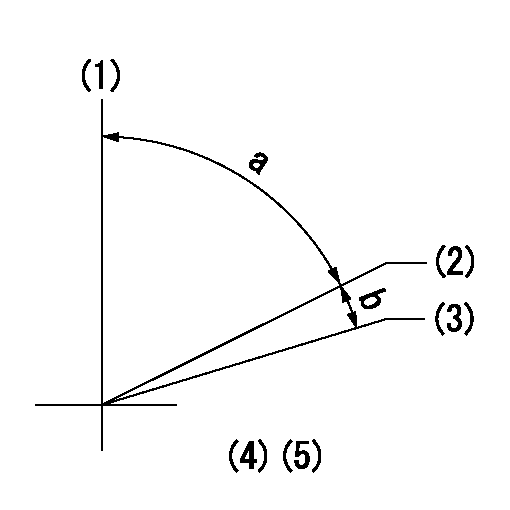

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK CAP: R1

(3)The torque control spring must does not have a set force.

(4)Rack difference between N = N1 and N = N2

(5)Idle sub spring setting: L1.

----------

K=10 R1=(17.5)mm N1=900r/min N2=500r/min L1=8-0.5mm

----------

----------

K=10 R1=(17.5)mm N1=900r/min N2=500r/min L1=8-0.5mm

----------

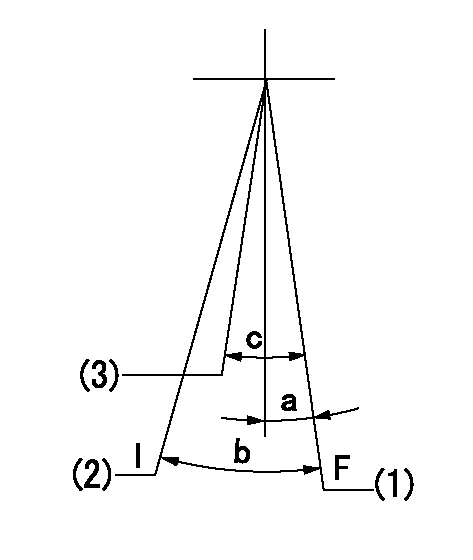

Speed control lever angle

F:Full speed

I:Idle

(1)Set the speed at aa, set the stopper bolt

(2)Stopper bolt setting

(3)Set the pump speed at bb.

----------

aa=955r/min bb=750r/min

----------

a=(1deg)+-5deg b=(23deg)+-5deg c=(6deg)+-5deg

----------

aa=955r/min bb=750r/min

----------

a=(1deg)+-5deg b=(23deg)+-5deg c=(6deg)+-5deg

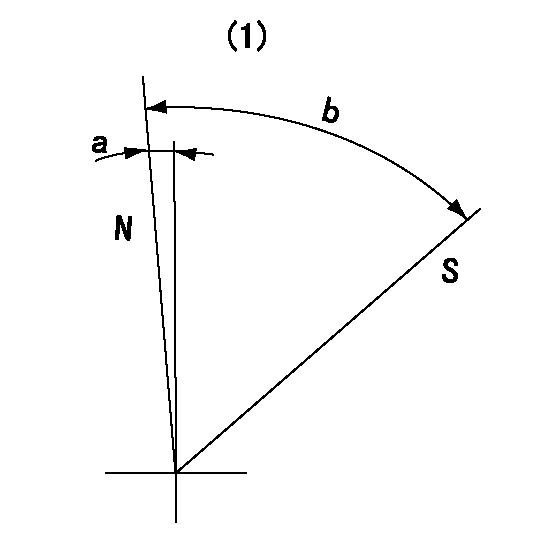

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

----------

----------

a=4deg+-5deg b=53deg+-5deg

----------

----------

a=4deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of key groove at No 1 cylinder's beginning of injection

(3)Stamp aligning marks on the pump housing flange.

(4)-

----------

----------

a=46deg18min+-3deg b=13deg42min+-30min

----------

----------

a=46deg18min+-3deg b=13deg42min+-30min

Information:

Introduction

Do not perform any procedure in this Special Instruction until you read this information and you understand this information.Affected Engines

This Special Instruction provides the proper instructions on accessing the timing hole for high pressure fuel pumps on C7 Engines. The procedure is for the C7 Engines that are in General Motors and Blue Bird chassis. The timing hole may need to be accessed after the high pressure fuel injection pump is replaced in order to time the new high pressure pump.Disassembly Procedure

Illustration 1 g01458243

(1) Clean Gas Induction (CGI) Cooler (2) Aftertreatment Regeneration Device (ARD) Housing Bracket (3) Timing Hole Plug (4) Aftertreatment Regeneration Device (ARD) Housing

Illustration 2 g01458244

(5) Mounting bolts for the bracket for the ARD housing

Remove the two mounting bolts (5) from the bracket for the housing for the ARD. Use a 18 millimeter socket in order to loosen the mounting bolts. Make sure that the socket can flex. Also use a 12 inch socket extension in order to loosen the mounting bolts. After the bolts have been broken loose the bolts must be turned by hand in order to finish removing the bolts.

Illustration 3 g01458245

(6) Exhaust clamp for the ARD

Loosen the exhaust clamp (6) for the ARD. Slide the exhaust clamp down the exhaust pipe. Do not remove the clamp completely. This may cause the clamp to become bent. This may cause the clamp to not fit properly.

Illustration 4 g01458247

(7) Timing hole for the high pressure fuel pump

Move the housing bracket for the ARD to the side. This will provide enough clearance in order to remove the plug from the timing hole.The timing hole can be used to check the timing for the fuel injection pump. If the fuel injection pump needs to be timed properly then refer to Disassembly and Assembly, RENR9707, "Fuel Injection Pump - Install" for the proper installation procedure to ensure the the fuel injection pump will be timed properly.Assembly Procedure

Illustration 5 g01458476

(3) Timing hole plug

Reinstall the timing hole plug (3) back into the timing hole.

Illustration 6 g01458245

(6) Exhaust clamp for the ARD

Reinstall the exhaust clamp (6) for the ARD.

Illustration 7 g01458244

(5) Mounting bolts for the housing bracket for the ARD

Move the bracket for the ARD into the original position. Reinstall the mounting bolts (5) for the mounting bracket for the ARD.

Do not perform any procedure in this Special Instruction until you read this information and you understand this information.Affected Engines

This Special Instruction provides the proper instructions on accessing the timing hole for high pressure fuel pumps on C7 Engines. The procedure is for the C7 Engines that are in General Motors and Blue Bird chassis. The timing hole may need to be accessed after the high pressure fuel injection pump is replaced in order to time the new high pressure pump.Disassembly Procedure

Illustration 1 g01458243

(1) Clean Gas Induction (CGI) Cooler (2) Aftertreatment Regeneration Device (ARD) Housing Bracket (3) Timing Hole Plug (4) Aftertreatment Regeneration Device (ARD) Housing

Illustration 2 g01458244

(5) Mounting bolts for the bracket for the ARD housing

Remove the two mounting bolts (5) from the bracket for the housing for the ARD. Use a 18 millimeter socket in order to loosen the mounting bolts. Make sure that the socket can flex. Also use a 12 inch socket extension in order to loosen the mounting bolts. After the bolts have been broken loose the bolts must be turned by hand in order to finish removing the bolts.

Illustration 3 g01458245

(6) Exhaust clamp for the ARD

Loosen the exhaust clamp (6) for the ARD. Slide the exhaust clamp down the exhaust pipe. Do not remove the clamp completely. This may cause the clamp to become bent. This may cause the clamp to not fit properly.

Illustration 4 g01458247

(7) Timing hole for the high pressure fuel pump

Move the housing bracket for the ARD to the side. This will provide enough clearance in order to remove the plug from the timing hole.The timing hole can be used to check the timing for the fuel injection pump. If the fuel injection pump needs to be timed properly then refer to Disassembly and Assembly, RENR9707, "Fuel Injection Pump - Install" for the proper installation procedure to ensure the the fuel injection pump will be timed properly.Assembly Procedure

Illustration 5 g01458476

(3) Timing hole plug

Reinstall the timing hole plug (3) back into the timing hole.

Illustration 6 g01458245

(6) Exhaust clamp for the ARD

Reinstall the exhaust clamp (6) for the ARD.

Illustration 7 g01458244

(5) Mounting bolts for the housing bracket for the ARD

Move the bracket for the ARD into the original position. Reinstall the mounting bolts (5) for the mounting bracket for the ARD.

Have questions with 101452-3123?

Group cross 101452-3123 ZEXEL

Komatsu

Komatsu

Komatsu

101452-3123

9 400 614 182

6204721422

INJECTION-PUMP ASSEMBLY

4D95L

4D95L