Information injection-pump assembly

ZEXEL

101451-9560

1014519560

Rating:

Cross reference number

ZEXEL

101451-9560

1014519560

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-4-3

Pre-stroke

mm

1.95

1.9

2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 90 89.5 90.5

Cyl.1-2 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cal 1-3 deg. 270 269.5 270.5

Cal 1-3 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.4

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

46.5

45.5

47.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

11.4

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

45

42

48

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

-

Rack position

7.9+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8

6.9

9.1

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Timer adjustment

Pump speed

r/min

500--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

450

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

2.1

1.6

2.6

Timer adjustment_04

Pump speed

r/min

1600

Advance angle

deg.

6.4

5.9

6.9

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

7.5

7.5

7.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

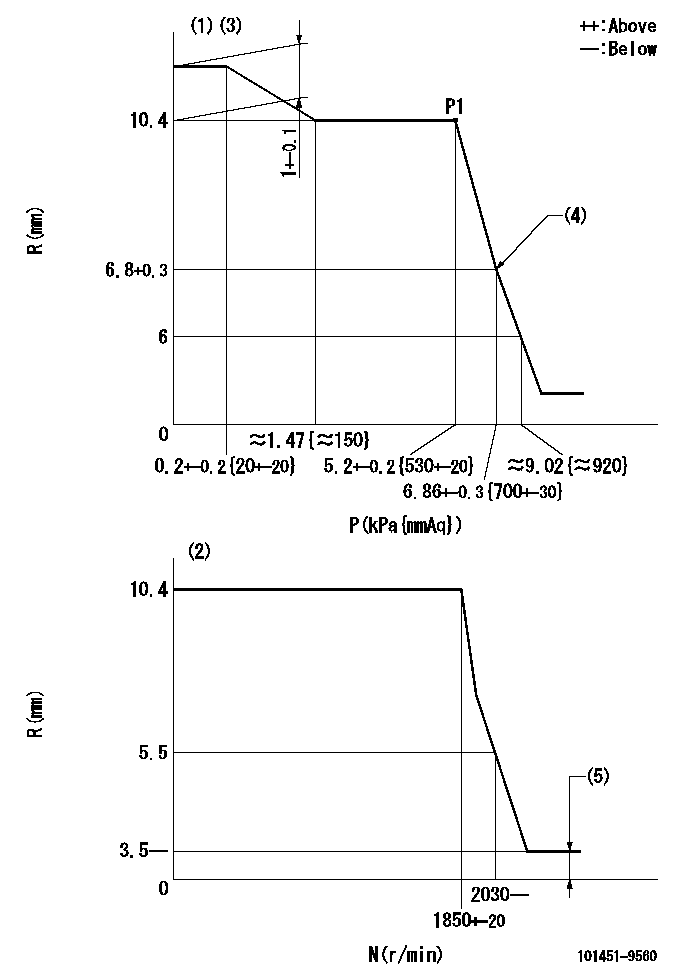

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

P:Negative pressure

(1)Pneumatic governor

(2)Mechanical governor

(3)Acting negative pressure: P1

(4)Beginning of idle sub spring operation: L1

(5)Injection quantity Q = Q1 or less

----------

L1=6.8+0.3mm Q1=3mm3/st

----------

----------

L1=6.8+0.3mm Q1=3mm3/st

----------

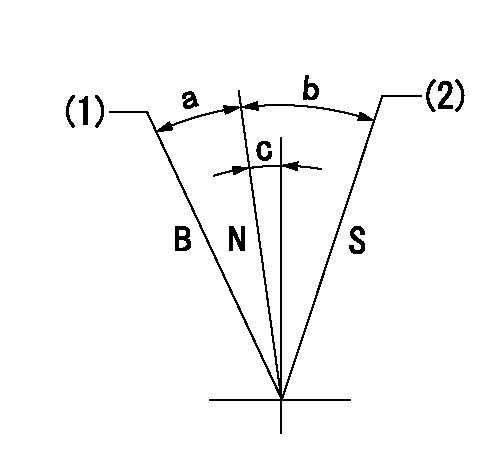

Speed control lever angle

S:Stop

B:When boosted

N:Normal

(1)Rack position = aa

(2)Rack position bb

----------

aa=18mm bb=0mm

----------

a=13deg+-5deg b=22deg+-3deg c=0deg+-5deg

----------

aa=18mm bb=0mm

----------

a=13deg+-5deg b=22deg+-3deg c=0deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Table 1

Service Tools

Part Number Part

Caterpillar Electronic Technician (ET)

6V-7070

9U-7330 Digital Multimeter

8T-3224 Needle Tip Group

7X-1710 Multimeter Probe Group

8T-8726 Adapter Cable Assembly

9U-7246 Connector Repair Kit

DT

4C-3406 Connector Repair Kit

4C-8195 Control Service Tool (Switch Box)

Illustration 1 g00774942

Connections for the Communication Adapter II and the Caterpillar Electronic Technician (ET)The components that are needed in order to use the Communication Adapter II and the Caterpillar Electronic Technician ( ET) in order to determine diagnostic codes are listed: (6) Cable (7) 171-4400 Communication Adapter II (8) Service diagnostic cable. (9) Current version of Cat ET software and an IBM-COMPATIBLE personal computerReferenceSee Special Publication, NEHS0758, "Communications Adapter II User's Manual Contains Software".Note: Caterpillar Electronic Technician (ET) is a software program that can be used on an IBM compatible personal computer. In order to use the Cat ET, order the following materials: Special Publication, JERD2124, "ET Single Use Program License", Special Publication, JEHP1026, "Information and Requirements Sheet", 7X-1425 Data Link Cable and the Data Subscription and Special Publication, JERD2142, "Data Subscription". The Special Publication, JEHP1026, "Information and Requirements Sheet" lists the required hardware and the features of the Cat ET.The Cat ET is not required in order to determine the diagnostic codes and the Cat ET is not required in order to clear the diagnostic codes. However, the process of determining the diagnostic codes is easier and faster by using the Cat ET. The Cat ET can also display information on the history of a diagnostic code and the parameter status of diagnostic codes. These features allow the Cat ET to be a useful tool for troubleshooting.The Cat ET is used to communicate to the electronic control module over the data link by connecting to the machine diagnostic connector. For more information and the locations of the connectors, see Troubleshooting, "Electrical Components and Connector Locations" and the Electrical System Schematic in your machine's Service Manual.For instructions on servicing Sure Seal connectors, see Special Instruction, SMHS7531. For instructions on servicing Deutsch connectors, see Special Instruction, SEHS9615.Use the digital multimeter for measuring resistance or for measuring voltage. For instructions about the use of the 6V-7070 Digital Multimeter, see Special Instruction, SEHS7734. The 7X-1710 Multimeter Probe measures the voltage at the connectors without disconnecting the connectors. The probe cables are pushed into the back of the connector along the wire. The 8T-8726 Adapter Cable has a breakout with 3 pins. The adapter cable is used for measurements in the sensor circuits.Note: Except for harness tests, using continuity testers such as the 8T-0500 Continuity Tester or voltage testers such as the 5P-7277 Voltage Tester is not recommended for today's Caterpillar electrical circuits.