Information injection-pump assembly

BOSCH

9 400 614 171

9400614171

ZEXEL

101451-9511

1014519511

NISSAN-DIESEL

16700T9019

16700t9019

Rating:

Service parts 101451-9511 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1660036W00

12.

Open Pre:MPa(Kqf/cm2)

11.8(120)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 171

9400614171

ZEXEL

101451-9511

1014519511

NISSAN-DIESEL

16700T9019

16700t9019

Zexel num

Bosch num

Firm num

Name

101451-9511

9 400 614 171

16700T9019 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

ED33 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

ED33 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2

1.95

2.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.9

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

61.2

57.2

65.2

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

12.3

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

57

56

58

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

-

Rack position

7.6+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

9.8

7.5

12.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

300++

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

450

Advance angle

deg.

0.7

Timer adjustment_04

Pump speed

r/min

700

Advance angle

deg.

1

0.5

1.5

Timer adjustment_05

Pump speed

r/min

1500

Advance angle

deg.

5

4.5

5.5

Timer adjustment_06

Pump speed

r/min

1750

Advance angle

deg.

6.5

6

7

Timer adjustment_07

Pump speed

r/min

-

Advance angle

deg.

7.5

7.5

7.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

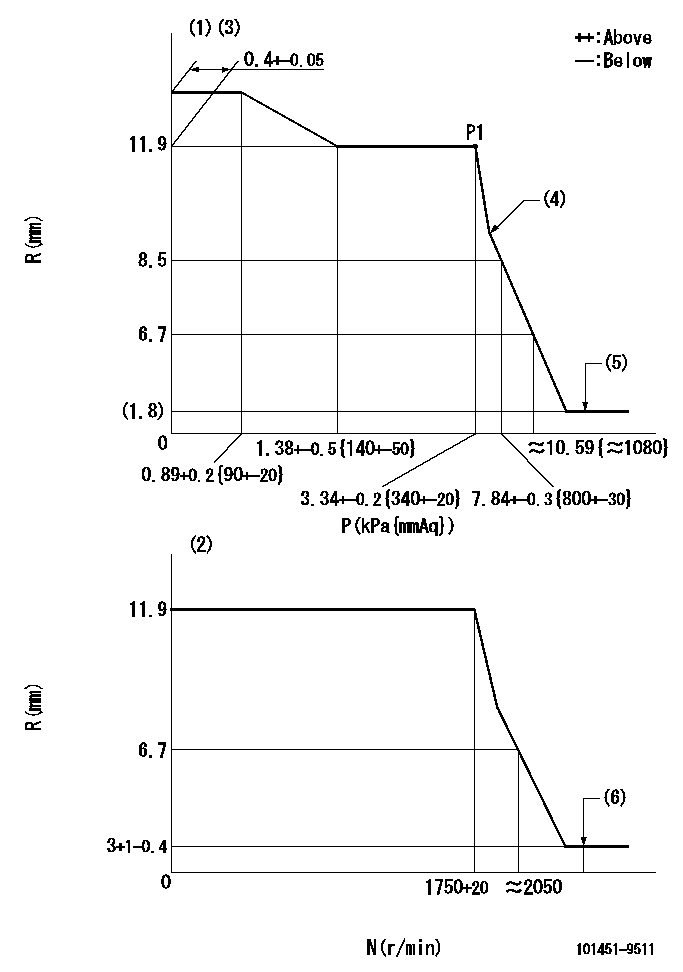

Governor adjustment

N:Pump speed

R:Rack position (mm)

P:Negative pressure

(1)Pneumatic governor

(2)Mechanical governor

(3)Acting negative pressure: P1

(4)Beginning of idle sub spring operation: L1

(5)With stopper disk.

(6)Injection quantity Q = Q1 or less

----------

L1=11.5+-0.3mm Q1=3mm3/st

----------

----------

L1=11.5+-0.3mm Q1=3mm3/st

----------

0000001101

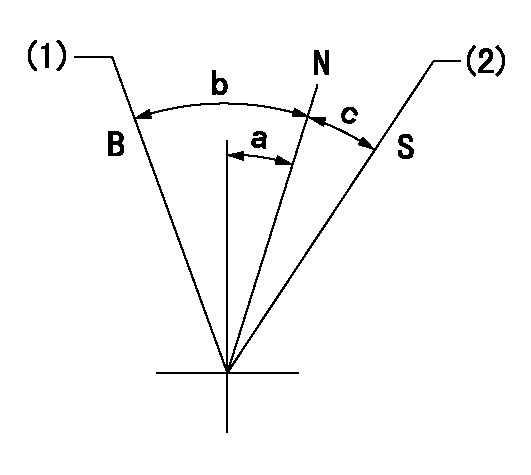

S:Stop

N:Normal

B:When boosted

(1)Rack position = aa

(2)Rack position bb

----------

aa=17.5mm bb=(1.8)mm

----------

a=7.5deg+-5deg b=10.5deg+-5deg c=21.5deg+-3deg

----------

aa=17.5mm bb=(1.8)mm

----------

a=7.5deg+-5deg b=10.5deg+-5deg c=21.5deg+-3deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'K' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(50deg)

----------

aa=12deg

----------

a=(50deg)

Information:

Table 1

Required Tools

Tool Part Number Part Description Qty

A 380-5200 Tool Kit 1

B 366-7782 Attenuator 1 Testing Procedure

Perform a "Manual Diesel Particulate Filter Regeneration" using the electronic service tool. If the "Manual Diesel Particulate Filter Regeneration" procedure follows the removal of excess oil from the exhaust system, proceed to Step 2.

Follow the procedure that is detailed by Step 1.b through to Step 1.m to clean oil from the exhaust system.

Remove excess oil from all pipes with a clean cloth.

Remove the DPF from the bracket for the clean emission module. Refer to Disassembly and Assembly, "Diesel Particulate Filter - Remove" for the correct procedure.

Use a suitable supporting device, position the DPF in a vertical position. Ensure that the inlet side of the DPF faces in a DOWNWARDS position.

Let the DPF drain overnight. The oil will collect inside the inlet face of the DPF. Position a suitable container under the inlet face of the DPF. Incline the inlet face of the DPF to drain the oil into the container.

If amount drained from DPF equals less than 1 L (0.26 US gal), proceed to Step 1.g. If amount is greater than 1 L (0.26 US gal), then the DPF should be replaced.

Remove excess oil from the inlet and outlet of the DPF with a clean cloth.

Install the DPF from the bracket for the clean emission module. Refer to Disassembly and Assembly, "Diesel Particulate Filter - Install" for the correct procedure.

Start the engine. Operate the engine a 100 percent throttle for a MINIMUM of 20 minutes. Do not operate the application under load at this time period.

After 20 minutes, use the electronic service tool to perform the "DPF Desulphation Procedure". The "DPF Desulphation Procedure" will last 60 minutes.

Once the "DPF Desulphation Procedure" has been completed, observe the soot load. If the soot load is at a value less than 80 percent, then the application can be returned to service.

Check the application for any signs of visible black smoke coming from the exhaust stack after the cleaning procedure has been completed. This could indicate a cracked DPF that will need to be replaced.Note: Black soot residue on the surface of the inside of the exhaust stack does not necessarily indicate a cracked DPF therefore should not be used in determining a problem with the DPF.

If white smoke does not dissipate, contact the Technical Communicator at a Caterpillar dealer. For further assistance, the Technical Communicator can confer with the Dealer Solutions Network.

After the manual DPF regeneration is complete, operate the engine at 1800 rpm for a MINIMUM of 20 minutes to stabilize the DPF temperatures.Note: The engine must maintain a steady speed for the entire duration of the test.

Hot engine components can cause injury from burns. Before performing maintenance on the engine, allow the engine and the components to cool.

Illustration 1 g02597531

Typical example (1) DPF Outlet Cap (2) Filter Paper (3) Hose Assembly (4) Air Pump

Illustration

Have questions with 101451-9511?

Group cross 101451-9511 ZEXEL

Nissan-Diesel

101451-9511

9 400 614 171

16700T9019

INJECTION-PUMP ASSEMBLY

ED33

ED33