Information injection-pump assembly

ZEXEL

101451-9300

1014519300

NISSAN-DIESEL

16700J6504

16700j6504

Rating:

Service parts 101451-9300 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-J6500

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Cross reference number

ZEXEL

101451-9300

1014519300

NISSAN-DIESEL

16700J6504

16700j6504

Zexel num

Bosch num

Firm num

Name

101451-9300

16700J6504 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

ED33 * K

ED33 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2

1.95

2.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.2

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

55.2

54.2

56.2

Max. variation between cylinders

%

0

-2.4

2.4

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.7+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

10.6

8.3

12.9

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

-

Rack position

-

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

55.2

54.7

55.7

Remarks

Smoke setting

Smoke setting

Timer adjustment

Pump speed

r/min

300--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

450

Advance angle

deg.

0.7

Timer adjustment_04

Pump speed

r/min

700

Advance angle

deg.

1

0.5

1.5

Timer adjustment_05

Pump speed

r/min

1500

Advance angle

deg.

5

4.5

5.5

Timer adjustment_06

Pump speed

r/min

1900

Advance angle

deg.

7.5

7

8

Remarks

Finish

Finish

Test data Ex:

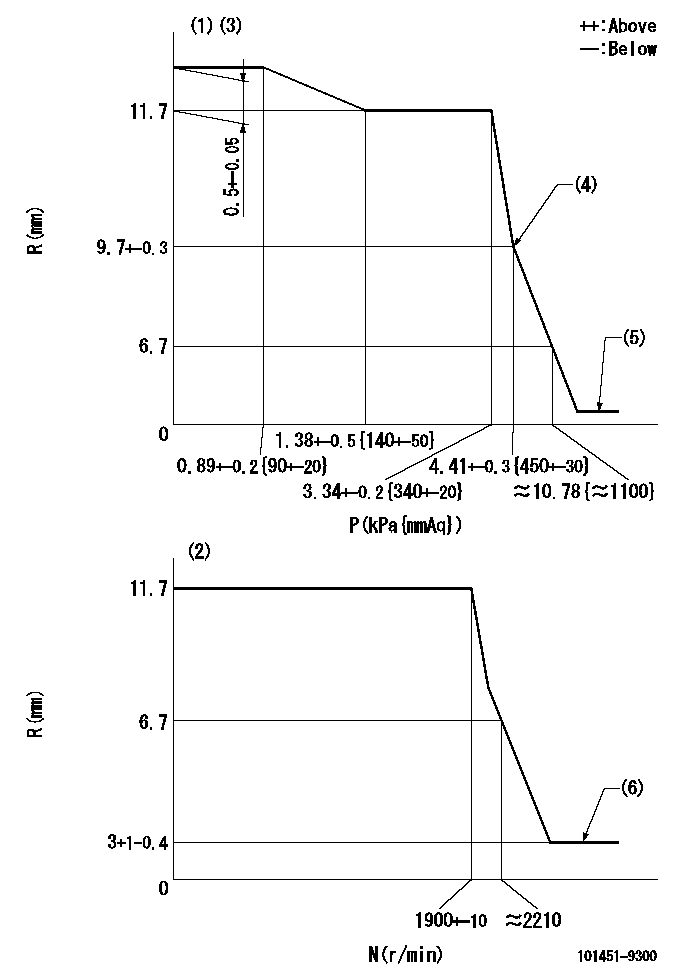

Governor adjustment

N:Pump speed

R:Rack position (mm)

P:Negative pressure

(1)Pneumatic governor

(2)Mechanical governor

(3)Acting negative pressure: P1

(4)Beginning of idle sub spring operation: L1

(5)With stop device.

(6)Injection quantity Q = Q1 or less

----------

L1=9.7+-0.3mm Q1=3mm3/st

----------

----------

L1=9.7+-0.3mm Q1=3mm3/st

----------

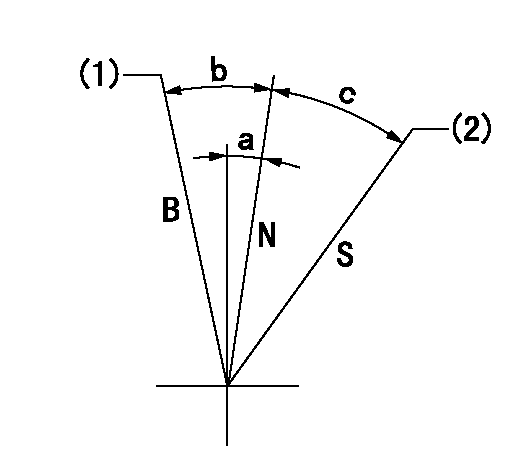

Speed control lever angle

B:When boosted

N:Normal

S:Stop

(1)Rack position = aa

(2)Rack position bb

----------

aa=16mm bb=(1.8)mm

----------

a=7.5deg+-5deg b=7deg+-5deg c=21.5deg+-3deg

----------

aa=16mm bb=(1.8)mm

----------

a=7.5deg+-5deg b=7deg+-5deg c=21.5deg+-3deg

0000001501 ACS

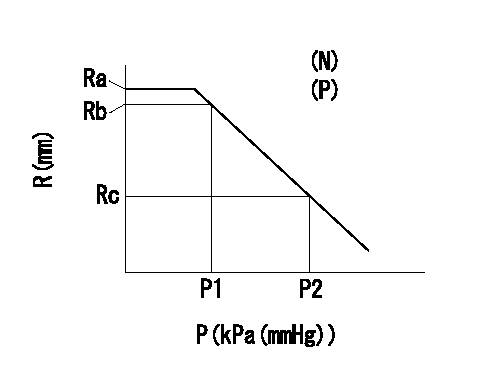

(N): Speed of the pump

(P): governor's negative pressure

(R) Rack position (mm)

Aneroid compensator adjustment

(1)Screw in the aneroid compensator body to obtain the performance shown in the graph above.

----------

----------

N=1000r/min P=0.69kPa(70mmAq) Ra=R1(12.2-0.05)mm Rb=R1-0.05mm Rc=11.6+-0.2mm P1=8-5.3kPa(60-40mmHg) P2=16.7kPa(125mmHg)

----------

----------

N=1000r/min P=0.69kPa(70mmAq) Ra=R1(12.2-0.05)mm Rb=R1-0.05mm Rc=11.6+-0.2mm P1=8-5.3kPa(60-40mmHg) P2=16.7kPa(125mmHg)

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '0' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(50deg)

----------

aa=12deg

----------

a=(50deg)

Information:

If the procedure did not correct the issue, contact your Cat dealer Technical Communicator (TC). For further assistance, your TC can confer with the Dealer Solutions Network (DSN).E1156(1) - Filter intake pressure greater than 10 kPa (1.50 psi) for more than 10 seconds. Refer to Table14 for troubleshooting.E1156(2) - Filter intake pressure greater than 15 kPa (2.25 psi) for more than 10 seconds. Refer to Table14 for troubleshooting.A faulty sensor may cause this diagnostic code. First determine that the sensor is not faulty.

Table 14

Troubleshooting Test Steps Values Results

1. Check for Associated Diagnostic Codes.

A. Establish communication between the Cat® Electronic Technician (ET) and the engine Electronic Control Module (ECM).

B. Troubleshoot any associated diagnostic codes that are present before continuing with this procedure.

Associated Diagnostic Codes

Result: An associated diagnostic code is not present.

Proceed to Test Step 2.

Result: An associated diagnostic code is active or logged.

1. Troubleshoot the associated diagnostic code before continuing with this procedure.

2. Service Maintenance.

A. Determine the most recent cleaning of the Wall Flow Filter (WFF).

Cleaning Interval

Result: The WFF was cleaned within the last 1000 hours.

Proceed to Test Step 3.

Result: The WFF was not cleaned within the last 1000 hours.

Proceed to Test Step 4.

3. Check for Contamination.

A. Reset all active codes and clear all logged codes.

B. Remove the WFF.

C. Check for contamination on the face of the WFF.

Contamination

Result: There is no sign of oil, fuel, or coolant on the WFF.

Proceed to Test Step 4.

Result: There is oil, fuel, or coolant on the WFF.

1. Diagnose the cause of the contamination.

2. The engine must be run with no load at 1400 rpm for at least 15 minutes, or until there is no white smoke.

3. If white smoke continues, or if the diagnostic code remains active, proceed to Test Step 5.

4. Clean the WFF.

A. Clean the WFF. Refer to "Wall Flow Diesel Particulate Filter - Clean".

B. Reset all active codes and clear all logged codes.

Clean was successful

Result: Cleaning the WFF was successful.

Return the machine to service.

Result: Cleaning the WFF was not successful.

1. Troubleshoot any diagnostic codes that are present, if no codes are present, proceed to Test Step 6.

5. Replace the WFF.

Replacement was successful

Result: Replacing the WFF was successful.

Return the machine to service.

If the procedure did not correct the issue, contact your Cat dealer Technical Communicator (TC). For further assistance, your TC can confer with the Dealer Solutions Network (DSN).Exhaust Temperature Is High

Certain operating conditions may cause the exhaust temperature to increase to a level that may damage engine components.Probable Causes

Boost Leak

Engine operating conditions

High altitude

Obstructed aftercooler

Table 15

Troubleshooting Test Steps Values Results

1. Check for Boost Leakage.

A. Apply a light load to the engine and check for boost leakage.

Boost Leaks

Result: Boost leakage was found.

Repair: Repair the leaks. Return the machine to service.

Result: Boost leakage was not found.

Proceed to Test Step 2.

2. Check the Engine Operating Conditions.

A. Check the histogram to determine if the high exhaust temperature was due to normal operation.

When possible, interview the operator. Determine if the engine is being operated under heavy load. Ensure that the engine is being operated at the

Table 14

Troubleshooting Test Steps Values Results

1. Check for Associated Diagnostic Codes.

A. Establish communication between the Cat® Electronic Technician (ET) and the engine Electronic Control Module (ECM).

B. Troubleshoot any associated diagnostic codes that are present before continuing with this procedure.

Associated Diagnostic Codes

Result: An associated diagnostic code is not present.

Proceed to Test Step 2.

Result: An associated diagnostic code is active or logged.

1. Troubleshoot the associated diagnostic code before continuing with this procedure.

2. Service Maintenance.

A. Determine the most recent cleaning of the Wall Flow Filter (WFF).

Cleaning Interval

Result: The WFF was cleaned within the last 1000 hours.

Proceed to Test Step 3.

Result: The WFF was not cleaned within the last 1000 hours.

Proceed to Test Step 4.

3. Check for Contamination.

A. Reset all active codes and clear all logged codes.

B. Remove the WFF.

C. Check for contamination on the face of the WFF.

Contamination

Result: There is no sign of oil, fuel, or coolant on the WFF.

Proceed to Test Step 4.

Result: There is oil, fuel, or coolant on the WFF.

1. Diagnose the cause of the contamination.

2. The engine must be run with no load at 1400 rpm for at least 15 minutes, or until there is no white smoke.

3. If white smoke continues, or if the diagnostic code remains active, proceed to Test Step 5.

4. Clean the WFF.

A. Clean the WFF. Refer to "Wall Flow Diesel Particulate Filter - Clean".

B. Reset all active codes and clear all logged codes.

Clean was successful

Result: Cleaning the WFF was successful.

Return the machine to service.

Result: Cleaning the WFF was not successful.

1. Troubleshoot any diagnostic codes that are present, if no codes are present, proceed to Test Step 6.

5. Replace the WFF.

Replacement was successful

Result: Replacing the WFF was successful.

Return the machine to service.

If the procedure did not correct the issue, contact your Cat dealer Technical Communicator (TC). For further assistance, your TC can confer with the Dealer Solutions Network (DSN).Exhaust Temperature Is High

Certain operating conditions may cause the exhaust temperature to increase to a level that may damage engine components.Probable Causes

Boost Leak

Engine operating conditions

High altitude

Obstructed aftercooler

Table 15

Troubleshooting Test Steps Values Results

1. Check for Boost Leakage.

A. Apply a light load to the engine and check for boost leakage.

Boost Leaks

Result: Boost leakage was found.

Repair: Repair the leaks. Return the machine to service.

Result: Boost leakage was not found.

Proceed to Test Step 2.

2. Check the Engine Operating Conditions.

A. Check the histogram to determine if the high exhaust temperature was due to normal operation.

When possible, interview the operator. Determine if the engine is being operated under heavy load. Ensure that the engine is being operated at the

Have questions with 101451-9300?

Group cross 101451-9300 ZEXEL

Nissan-Diesel

101451-9300

16700J6504

INJECTION-PUMP ASSEMBLY

ED33

ED33