Information injection-pump assembly

BOSCH

9 400 613 255

9400613255

ZEXEL

101443-9060

1014439060

NISSAN-DIESEL

16790NA004

16790na004

Rating:

Service parts 101443-9060 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1660043G03

12.

Open Pre:MPa(Kqf/cm2)

9.8{100}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 255

9400613255

ZEXEL

101443-9060

1014439060

NISSAN-DIESEL

16790NA004

16790na004

Zexel num

Bosch num

Firm num

Name

101443-9060

9 400 613 255

16790NA004 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

TD27 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

TD27 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.15

2.1

2.2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

40.1

39.1

41.1

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.9+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

8

6.9

9.1

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

C

Rack position

12++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

45

55

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

500--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

450

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1300

Advance angle

deg.

4

3.5

4.5

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

7.3

7.3

7.3

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

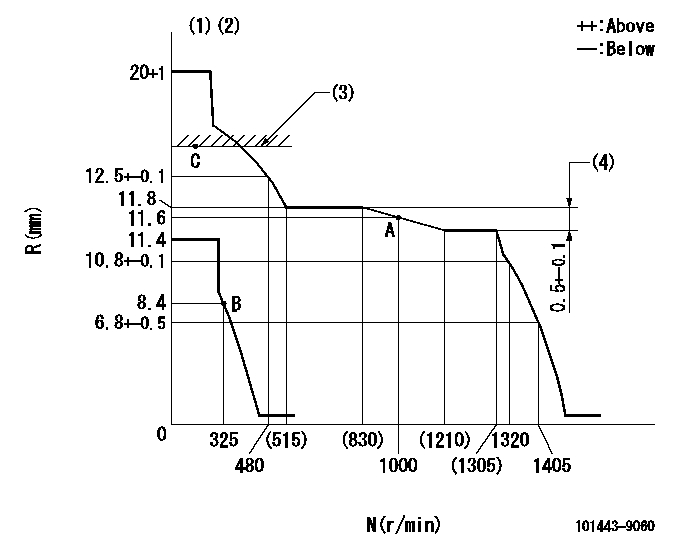

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Rack difference between N = N1 and N = N2

----------

K=15 N1=1270r/min N2=750r/min

----------

----------

K=15 N1=1270r/min N2=750r/min

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=24deg+-5deg b=16deg+-5deg

----------

----------

a=24deg+-5deg b=16deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=12deg+-5deg b=53deg+-5deg

----------

----------

a=12deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'ZZ' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(100deg)

----------

aa=16deg

----------

a=(100deg)

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

The DOC/DPF can become plugged if an NRS cooler failure occurs and coolant passes out the exhaust. Solution

If an engine has an NRS cooler failure, the DPF and DOC will need inspected for calcium deposits. In some cases calcium has partially filled the DPF and caused frequent regeneration issues, and erratic high soot loading readings.

Illustration 1 g03374496

Example of calcium deposits on DPF face

Illustration 2 g03374497

Example of calcium deposits on DPF faceThe calcium deposits will be a white and black powdery mixture on the face of the DPF and the DOC. Refer to Illustrations 1 and 2 for examples of a DPF with calcium plugging on the DPF face.Refer to Reuse And Salvage Guidelines, SEBF9223, "Inspection of Diesel Particulate Filters and Diesel Oxidation Catalysts for Tier 4 Machine and Industrial Engines" for further assistance.

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

The DOC/DPF can become plugged if an NRS cooler failure occurs and coolant passes out the exhaust. Solution

If an engine has an NRS cooler failure, the DPF and DOC will need inspected for calcium deposits. In some cases calcium has partially filled the DPF and caused frequent regeneration issues, and erratic high soot loading readings.

Illustration 1 g03374496

Example of calcium deposits on DPF face

Illustration 2 g03374497

Example of calcium deposits on DPF faceThe calcium deposits will be a white and black powdery mixture on the face of the DPF and the DOC. Refer to Illustrations 1 and 2 for examples of a DPF with calcium plugging on the DPF face.Refer to Reuse And Salvage Guidelines, SEBF9223, "Inspection of Diesel Particulate Filters and Diesel Oxidation Catalysts for Tier 4 Machine and Industrial Engines" for further assistance.

Have questions with 101443-9060?

Group cross 101443-9060 ZEXEL

Daewoo

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

101443-9060

9 400 613 255

16790NA004

INJECTION-PUMP ASSEMBLY

TD27

TD27