Information injection-pump assembly

ZEXEL

101442-0080

1014420080

ISUZU

8944369910

8944369910

Rating:

Service parts 101442-0080 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-94419-125-1

12.

Open Pre:MPa(Kqf/cm2)

13.7{140}

15.

NOZZLE SET

Include in #1:

101442-0080

as INJECTION-PUMP ASSEMBLY

Include in #2:

104740-0192

as _

Cross reference number

ZEXEL

101442-0080

1014420080

ISUZU

8944369910

8944369910

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

1.95

1.9

2

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

6.2

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

29.7

28.7

30.7

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

5.2+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

8

6.5

9.5

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

55

55

65

Fixing the lever

*

Rack limit

*

Test data Ex:

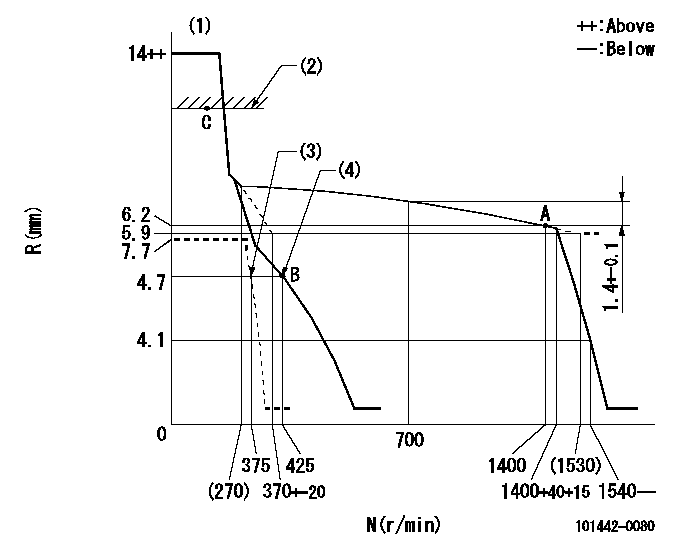

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Set idle sub-spring

(4)Main spring setting

----------

K=16

----------

----------

K=16

----------

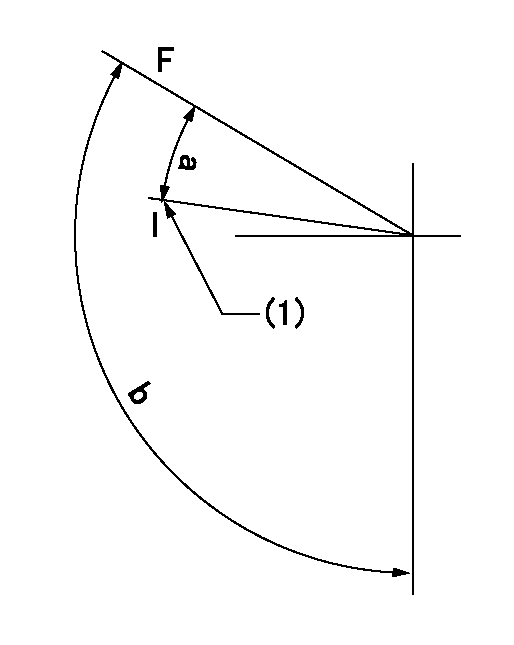

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=26deg+-5deg b=116deg+-5deg

----------

----------

a=26deg+-5deg b=116deg+-5deg

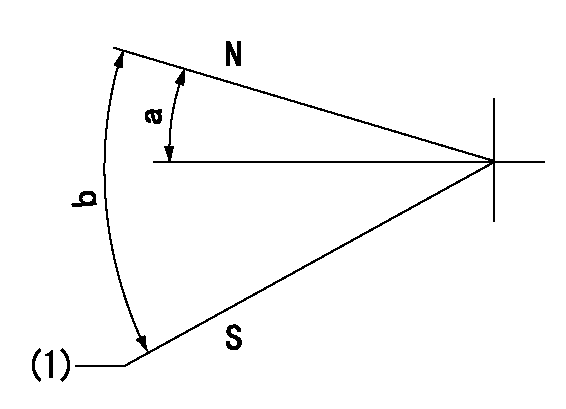

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At delivery

----------

----------

a=7.5deg+-5deg b=53deg+-5deg

----------

----------

a=7.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=17deg

----------

a=(50deg)

----------

aa=17deg

----------

a=(50deg)

Information:

Problems during boot up

The connections should be securely fastened.

The device drivers should be installed correctly.

The jumpers on add-in boards should be positioned correctly.

Format the hard drive and set up the monitor in the BIOS.

Ensure that the DIMM is properly installed. The DIMM may need to be reinstalled in order to ensure a good connection.

The EIDE cable from the hard drive should be properly connected.

Check if the system will start with a floppy disk.

The BIOS should be properly configured. Refer to Specifications, "Basic Input Output System".Problems after start-up

Check for loose connections. Check that all ISA/PCI cards are connected securely. Check that the DIMM is fully installed.

Check the system for overheating. Check the diagnostics indicator on the display of the front panel. Check that the chassis fan is working and that the filter is clean.

The monitor has a protected power supply that is regulated. A transient voltage in the power line or peripheral cable may cause the system to lock up. A transient voltage may cause a flashing display. The monitor may restart unexpectedly. You should exit the application if this occurs. Then, restart the application.

Check the EIDE cable from the hard drive for a proper connection.

Check if the system will start with a floppy disk.

Clean the CMOS by removing and reinstalling the battery. The battery is located on the backplane. The BIOS setup will then need to be run. Refer to Specifications, "Basic Input Output System".

The software package may need to be reinstalled.Incorrect characters are displayed or distorted

The display contrast control and the display brightness control may need to be properly adjusted. The setup functions are found in the operating system that contains the video driver.

If you use the integrated display, disconnect the chassis from the bezel. Check the connection to the display.The hard drive active indicator does not come on when the hard drive is being accessed

Check the EIDE cable connections to the drive.

Check that the BIOS setup is configured properly. The drive should be enabled.

Check the connections on the I/O board.

Restart the monitor.The power on indicator does not light

Check the power.

Check the front panel connector on the processor board.

Check the connections on the I/O board.

The connections should be securely fastened.

The device drivers should be installed correctly.

The jumpers on add-in boards should be positioned correctly.

Format the hard drive and set up the monitor in the BIOS.

Ensure that the DIMM is properly installed. The DIMM may need to be reinstalled in order to ensure a good connection.

The EIDE cable from the hard drive should be properly connected.

Check if the system will start with a floppy disk.

The BIOS should be properly configured. Refer to Specifications, "Basic Input Output System".Problems after start-up

Check for loose connections. Check that all ISA/PCI cards are connected securely. Check that the DIMM is fully installed.

Check the system for overheating. Check the diagnostics indicator on the display of the front panel. Check that the chassis fan is working and that the filter is clean.

The monitor has a protected power supply that is regulated. A transient voltage in the power line or peripheral cable may cause the system to lock up. A transient voltage may cause a flashing display. The monitor may restart unexpectedly. You should exit the application if this occurs. Then, restart the application.

Check the EIDE cable from the hard drive for a proper connection.

Check if the system will start with a floppy disk.

Clean the CMOS by removing and reinstalling the battery. The battery is located on the backplane. The BIOS setup will then need to be run. Refer to Specifications, "Basic Input Output System".

The software package may need to be reinstalled.Incorrect characters are displayed or distorted

The display contrast control and the display brightness control may need to be properly adjusted. The setup functions are found in the operating system that contains the video driver.

If you use the integrated display, disconnect the chassis from the bezel. Check the connection to the display.The hard drive active indicator does not come on when the hard drive is being accessed

Check the EIDE cable connections to the drive.

Check that the BIOS setup is configured properly. The drive should be enabled.

Check the connections on the I/O board.

Restart the monitor.The power on indicator does not light

Check the power.

Check the front panel connector on the processor board.

Check the connections on the I/O board.