Information injection-pump assembly

BOSCH

9 400 614 154

9400614154

ZEXEL

101442-0071

1014420071

ISUZU

8944143442

8944143442

Rating:

Service parts 101442-0071 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-94419-125-1

12.

Open Pre:MPa(Kqf/cm2)

13.7{140}

15.

NOZZLE SET

Include in #1:

101442-0071

as INJECTION-PUMP ASSEMBLY

Include in #2:

104740-0162

as _

Cross reference number

BOSCH

9 400 614 154

9400614154

ZEXEL

101442-0071

1014420071

ISUZU

8944143442

8944143442

Zexel num

Bosch num

Firm num

Name

101442-0071

9 400 614 154

8944143442 ISUZU

INJECTION-PUMP ASSEMBLY

4FE1 * K 14BC PE4A,5A, PE

4FE1 * K 14BC PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

1.95

1.9

2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

7.1

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

26.9

25.9

27.9

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.5+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

8

6.5

9.5

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

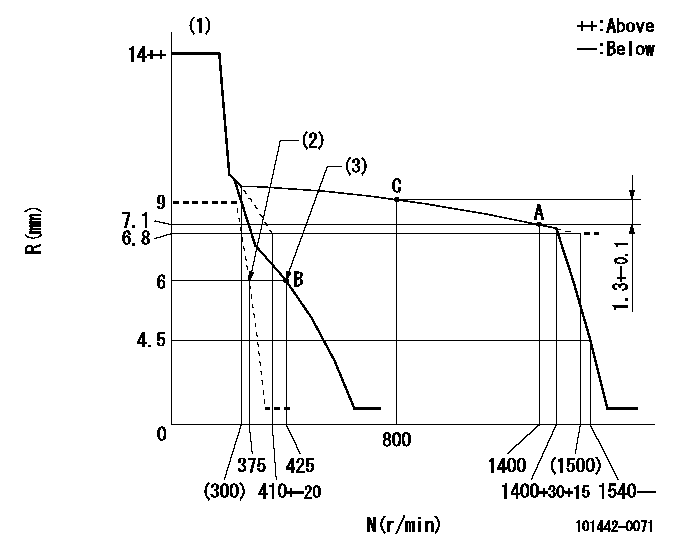

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Set idle sub-spring

(3)Main spring setting

----------

K=19

----------

----------

K=19

----------

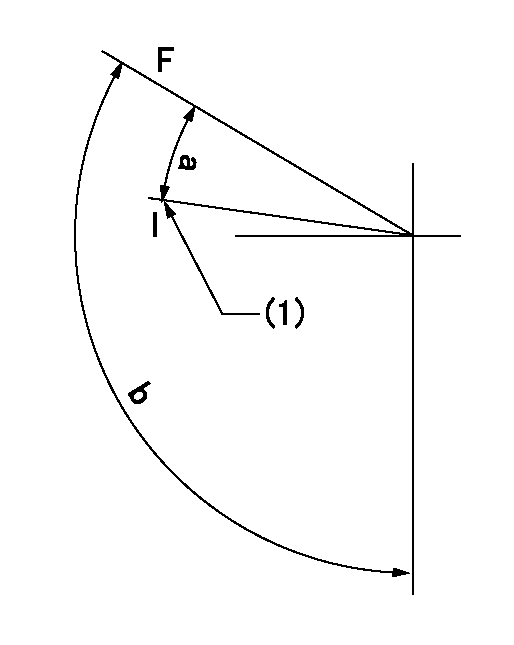

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=24deg+-5deg b=120deg+-5deg

----------

----------

a=24deg+-5deg b=120deg+-5deg

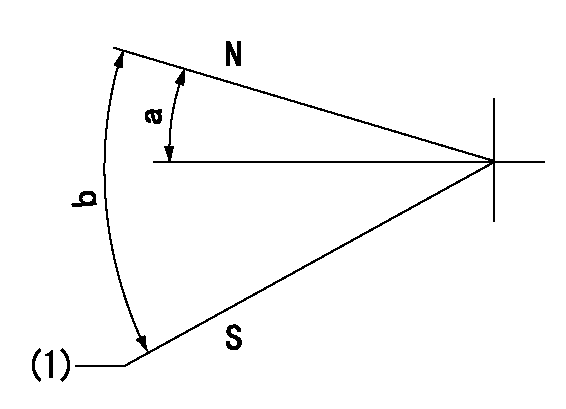

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At delivery

----------

----------

a=7.5deg+-5deg b=53deg+-5deg

----------

----------

a=7.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=17deg

----------

a=(50deg)

----------

aa=17deg

----------

a=(50deg)

Information:

Illustration 1 g00858201

(1) PCI Slot (2) Shared PCI/ISA Slot (3) DIMM Memory (4) Slot Cover (5) I/O Card Slot (6) CPU Slot (7) ScrewIn order to install the CPU board, perform the following procedure:

Remove the board from the anti-static packaging. Place the board on a ground, static free surface.

Illustration 2 g00858199

(8) Jumper JP2

The instructions for the board explain the locations of any jumpers or switches that need to be placed.Note: If you are replacing the CPU board, make a careful note of the cables that are attached to the existing CPU board. This will help you reconnect the cables to the new board.Note: The CPU board contains a video jumper setting that is specific to each version of the monitor. If jumper JP2 (8) is set incorrectly, the monitor video circuitry may be damaged.

Hold the board by the edges. Press the board firmly into the connector on the processor board.Note: Do not disturb the air flow director. The air flow director is required in order to keep the CPU cool. The air flow director should be routed behind the two add-in card slots. The air flow director should extend alongside the CPU heatsink.

Illustration 3 g00860148

(9) Board Retainer (10) Screw

Align the notch in the board retainer with the threaded hole. Install the screw. Hold the notch tightly against the screw before you tighten the screw.Note: Install the retainer tightly against the screw. If the retainer is not correctly installed, problems may occur when you insert an adjacent board.

Have questions with 101442-0071?

Group cross 101442-0071 ZEXEL

Isuzu

101442-0071

9 400 614 154

8944143442

INJECTION-PUMP ASSEMBLY

4FE1

4FE1