Information injection-pump assembly

BOSCH

9 400 610 076

9400610076

ZEXEL

101441-9430

1014419430

NISSAN-DIESEL

1670039G00

1670039g00

Rating:

Service parts 101441-9430 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-36W00

12.

Open Pre:MPa(Kqf/cm2)

9.8{100}

15.

NOZZLE SET

Include in #1:

101441-9430

as INJECTION-PUMP ASSEMBLY

Include in #2:

105866-4241

as _

Cross reference number

BOSCH

9 400 610 076

9400610076

ZEXEL

101441-9430

1014419430

NISSAN-DIESEL

1670039G00

1670039g00

Zexel num

Bosch num

Firm num

Name

101441-9430

9 400 610 076

1670039G00 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

SD25 * K 14BC INJECTION PUMP ASSY PE4A,5A, PE

SD25 * K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.15

2.1

2.2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.3

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

41

40

42

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.2+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8

6.9

9.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

800

Advance angle

deg.

0.6

0.1

1.1

Timer adjustment_04

Pump speed

r/min

1200

Advance angle

deg.

2

1.5

2.5

Timer adjustment_05

Pump speed

r/min

1800

Advance angle

deg.

5

4.5

5.5

Timer adjustment_06

Pump speed

r/min

2000

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

Test data Ex:

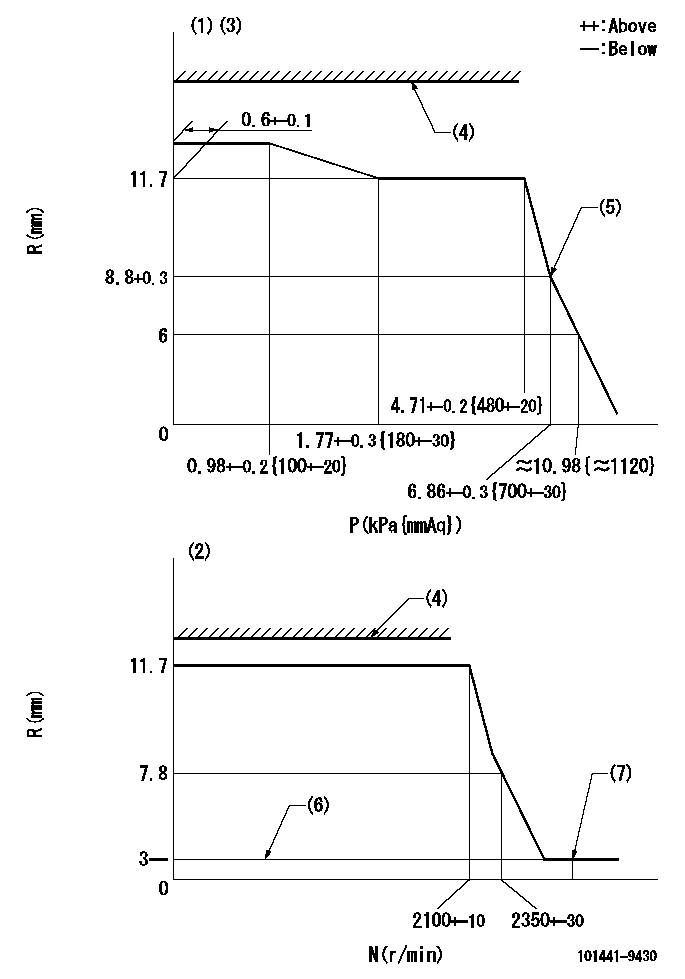

Governor adjustment

N:Pump speed

R:Rack position (mm)

P:Negative pressure

(1)Pneumatic governor

(2)Mechanical governor

(3)Acting negative pressure: P1

(4)RACK LIMIT: RAL

(5)Beginning of idle sub spring operation: L1

(6)Without stopper disk

(7)Injection quantity Q = Q1 or less (at N = N1)

----------

P1=2.94+-0.2kPa(300+-20mmAq) RAL=14.7-0.3mm L1=8.8+0.3mm Q1=3mm3/st N1=(2600)r/min

----------

----------

P1=2.94+-0.2kPa(300+-20mmAq) RAL=14.7-0.3mm L1=8.8+0.3mm Q1=3mm3/st N1=(2600)r/min

----------

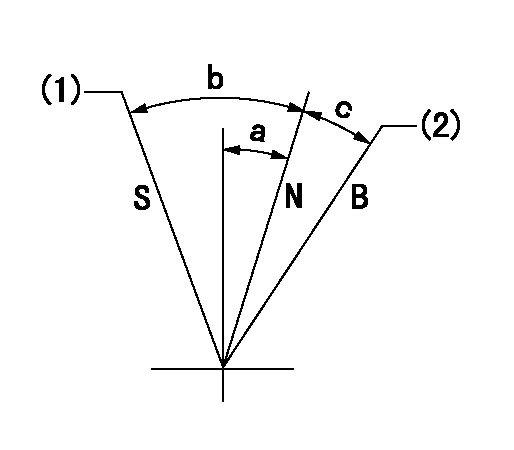

Speed control lever angle

B:When boosted

N:Normal

S:Stop

(1)Rack position = aa

(2)Rack position corresponding to cc

----------

aa=0mm bb=15mm

----------

a=1deg+-5deg b=24deg+-3deg c=5deg+-5deg

----------

aa=0mm bb=15mm

----------

a=1deg+-5deg b=24deg+-3deg c=5deg+-5deg

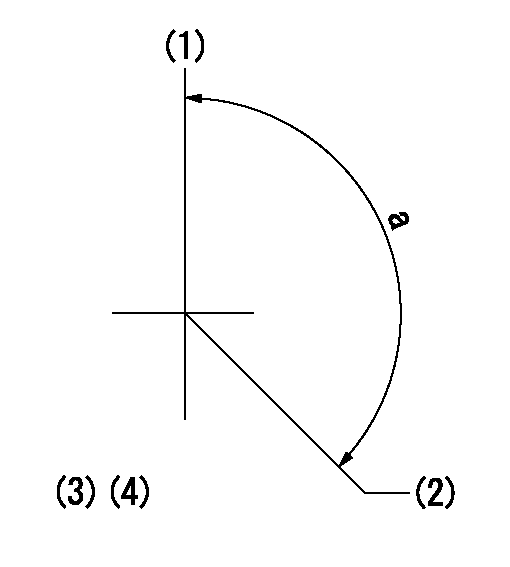

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'Y' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(140deg)

----------

aa=18deg

----------

a=(140deg)

Information:

Illustration 17 g03389921

Illustration 18 g03389931

Read the warning and select "Accept" to continue.

Illustration 19 g03389947

Once the reset is completed, a log of the reset is captured and visible as a new row of information in the Diesel Oxidation Catalyst Replacement screen. Selective Catalytic Reduction (SCR) Maintenance on Tier 4 Final Products

Note: Refer to Table 5 for the existing SCR catalyst part number being serviced along with the corresponding new service kit, and the clamp part number required for reassembly.

Table 5

SCR Part Number Service Kit Part Number Required Clamp Part Number

447-8145 N/A 346-0335

447-8143 N/A 346-0335

447-8141 N/A 346-0335

447-8149 N/A 346-0335

447-8147 N/A 346-0335

447-8163 N/A 346-0335

447-8151 N/A 346-0335

375-0989 N/A 346-0335

447-8165 N/A 346-0335

447-8153 N/A 346-0335

447-8161 N/A 346-0335

447-8159 N/A 346-0335

447-8157 N/A 346-0335

447-8169 N/A 346-0335

447-8173 N/A 346-0335

447-8171 N/A 346-0335

447-8167 N/A 346-0335

447-8175 N/A 346-0335 The Aftertreatment SCR Catalyst Replacement procedure must be performed when the SCR Catalyst has been replaced. This is necessary to ensure that the engine meets emissions requirements. Follow the procedure below to reset the SCR Catalyst model in the aftertreatment software.

Connect to Cat® ET.

Illustration 20 g03390636

Connect to "Engine #1 Aftertreatment Controller".

Illustration 21 g03740190

Select "Service" from the top menu and select "Service Procedures".

Illustration 22 g03740205

Select "Aftertreatment #1 SCR Catalyst Replacement" and select "Start".

Illustration 23 g03740210

Select "Reset".

Illustration 24 g03740216

You must read the warning and select "Accept" to continue.

Enter the factory passwords to continue.

Illustration 25 g03740230

Once the reset is completed, a log of the reset is captured and visible as a new row of information in the "Aftertreatment #1 SCR Catalyst Replacement" screen.

Have questions with 101441-9430?

Group cross 101441-9430 ZEXEL

Nissan-Diesel

101441-9430

9 400 610 076

1670039G00

INJECTION-PUMP ASSEMBLY

SD25

SD25