Information injection-pump assembly

ZEXEL

101441-9300

1014419300

NISSAN-DIESEL

1670029W06

1670029w06

Rating:

Cross reference number

ZEXEL

101441-9300

1014419300

NISSAN-DIESEL

1670029W06

1670029w06

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.15

2.1

2.2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.3

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

38.3

37.3

39.3

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

11.4

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

38

36.4

39.6

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

-

Rack position

8.7+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8

6.9

9.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

-

Rack position

-

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

38.3

37.8

38.8

Remarks

Set full load.

Set full load.

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

2.1

1.6

2.6

Timer adjustment_04

Pump speed

r/min

2100

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

Test data Ex:

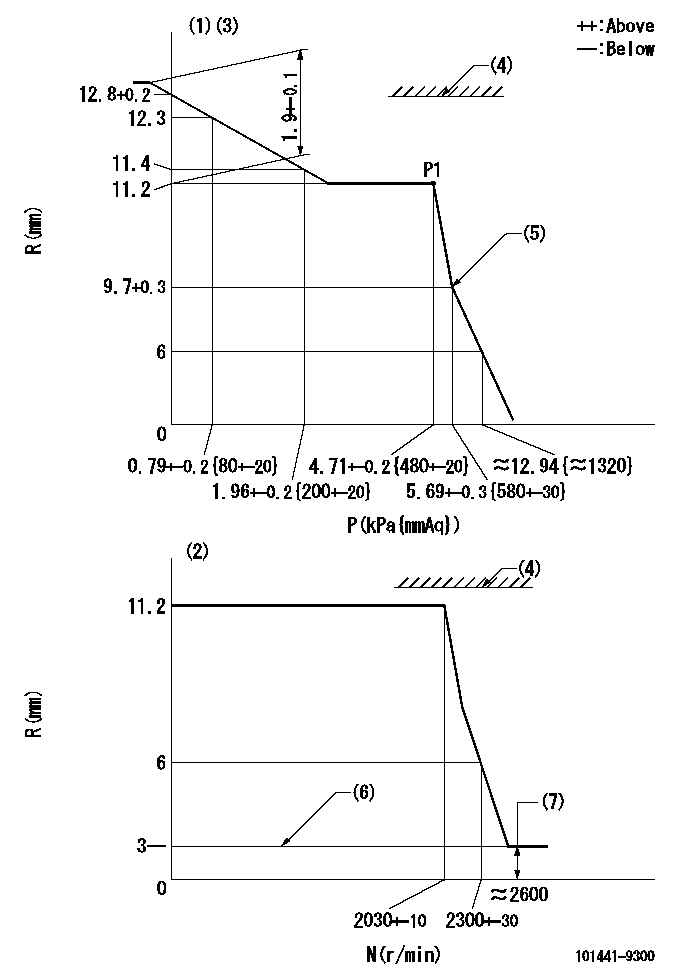

Governor adjustment

N:Pump speed

R:Rack position (mm)

P:Negative pressure

(1)Pneumatic governor

(2)Mechanical governor

(3)Acting negative pressure: P1

(4)RACK LIMIT: RAL

(5)Beginning of idle sub spring operation: L1

(6)Without stopper disk

(7)Injection quantity Q = Q1 or less

----------

RAL=14.7-0.3mm L1=9.7+0.3mm Q1=3mm3/st

----------

----------

RAL=14.7-0.3mm L1=9.7+0.3mm Q1=3mm3/st

----------

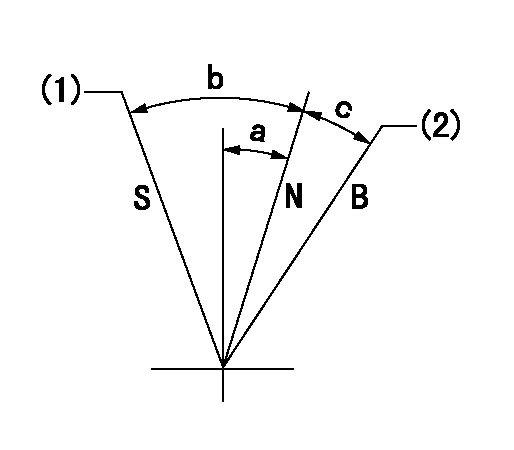

Speed control lever angle

N:Normal

B:When boosted

S:Stop

(1)Rack position = aa

(2)Rack position corresponding to bb

----------

aa=0mm bb=15mm

----------

a=1deg+-5deg b=26deg+-3deg c=3.5deg+-5deg

----------

aa=0mm bb=15mm

----------

a=1deg+-5deg b=26deg+-3deg c=3.5deg+-5deg

0000001501 ACS

(N): Speed of the pump

(P): governor's negative pressure

(Pa): aneroid compensator's negative pressure

(A) rubber boot

(B) Nut

(c) Nut

(D) Lever

1. Aneroid compensator installation

(1)Turn nut (C) to adjust gap to L1. (Remove rubber boot at adjustment.)

(2)Lock using nut (B).

(3)After installation, the lever D must move smoothly when the lever D is moved to the excess fuel side, and R = R1 or more.

----------

L1=0.1~0.5mm

----------

N=1000r/min P=2.94kPa(300mmAq) R1=R1(11.2)mm R2=(R1-0.6)mm R3=(R1-0.8)+-0.2mm R4=(R1-1.2)mm Pa1=1.23kPa(125mmHg) Pa2=1.61kPa(164mmHg) Pa3=2.29kPa(234mmHg)

----------

L1=0.1~0.5mm

----------

N=1000r/min P=2.94kPa(300mmAq) R1=R1(11.2)mm R2=(R1-0.6)mm R3=(R1-0.8)+-0.2mm R4=(R1-1.2)mm Pa1=1.23kPa(125mmHg) Pa2=1.61kPa(164mmHg) Pa3=2.29kPa(234mmHg)

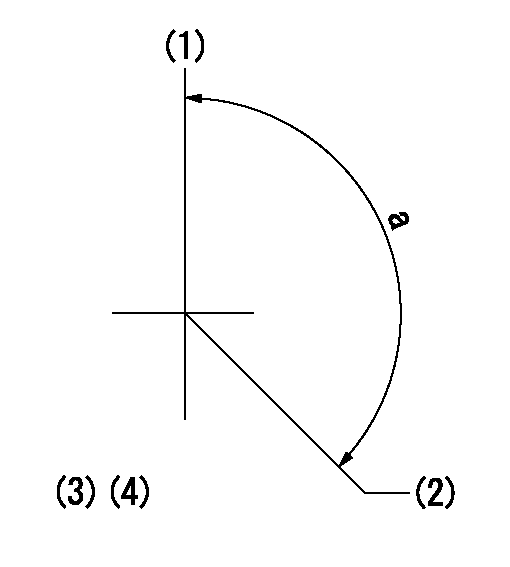

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'Y' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(140deg)

----------

aa=16deg

----------

a=(140deg)

Information:

Introduction

The problem that is identified now has a known permanent solution. Components to perform repairs are limited at this time. Review the solution below for further details. Problem

Caterpillar is aware of recent failures of the 8N-1721 Connecting Rod and the 8N-1984 Connecting Rod on certain diesel and gas applications of 3300 engines. Primary failure mode is a ventilated cylinder block due to the connecting rod crank end failure. All failures have occurred before 500 hours in service. Root cause has been identified and the team is working to resolve the issue. Solution

A "Quality Hold" is active for all new assemblies that utilize the 8N-1984 Connecting Rod and the 8N-1721 Connecting Rod manufactured between 01April 2011 and 31December 2012. The "Quality Hold" is applicable to all Morton service stock also.Cat ® Reman has identified a list of part numbers for Service kits, Piston Packs, and Rod Assembly boxes that may contain defective factory connecting rod assemblies. Dealers are advised not to use any factory new connecting rod assemblies that are found in the kits or assemblies prior to examination. Refer to Table 1.

Table 1

Service kit, Piston Pack, and Rod Assembly Part Numbers That May Contain the Defective New Connecting Rod Assemblies

8N-1721 20R-1439 20R-1474

0R-1696 20R-1428 20R-1660

0R-1697 0R-9206 20R-1442

0R-3043 20R-1462 20R-1482

10R-3637 20R-1455 20R-1483

10R-9259 20R-1477 20R-1451

0R-1694 20R-1472 20R-1450

0R-4284 20R-1448 20R-1445

0R-1695 20R-1446 20R-1443

0R-4635 20R-1468 20R-1426

0R-4488 20R-1466 20R-1423

0R-4506 20R-1441 0R-2078

0R-3044 20R-1437 0R-3258

0R-2080 20R-1435 20R-1665

0R-3259 20R-1434 20R-1663

0R-3612 20R-1429 20R-1675

0R-3610 20R-1424 0R-3661

10R-6152 0R-2557 0R-1692

20R-1673 0R-2079 0R-1693

20R-1664 20R-1341 0R-3660

0R-4949 0R-2555 0R-3662

0R-9205 0R-3613 20R-1127

0R-2556 0R-4956 8N-1984

0R-3706 0R-2554

10R-1851 0R-4948

10R-1636 10R-0889

10R-1840 0R-3611

0R-2077 10R-7253

20R-1454 0R-7444 When an engine failure occurs due to the connecting rod assembly, dealers are asked to contact the Dealer Solution Network (DSN) Tier 2 core engine service engineer at Mossville Engine Center (MEC) to expedite support to the customer.To support field repairs and rebuilds, dealers are advised to inspect the manufacture date on any 3304, G3304, 3306, or G3306 engine with the 8N-1984 Connecting Rod , the 8N-1721 Connecting Rod , the 0R-0914 Connecting Rod , and the 0R-0915 Connecting Rod , used to perform repairs. If the manufacture date is within the suspect date range, do not use the part. Parts stocking service letters will be released soon to address suspect material in dealer inventories. Markings on the Suspect 8N-1984 Connecting Rod and the 8N-1721 Connecting Rod

Illustration 1 g03342875

(1

The problem that is identified now has a known permanent solution. Components to perform repairs are limited at this time. Review the solution below for further details. Problem

Caterpillar is aware of recent failures of the 8N-1721 Connecting Rod and the 8N-1984 Connecting Rod on certain diesel and gas applications of 3300 engines. Primary failure mode is a ventilated cylinder block due to the connecting rod crank end failure. All failures have occurred before 500 hours in service. Root cause has been identified and the team is working to resolve the issue. Solution

A "Quality Hold" is active for all new assemblies that utilize the 8N-1984 Connecting Rod and the 8N-1721 Connecting Rod manufactured between 01April 2011 and 31December 2012. The "Quality Hold" is applicable to all Morton service stock also.Cat ® Reman has identified a list of part numbers for Service kits, Piston Packs, and Rod Assembly boxes that may contain defective factory connecting rod assemblies. Dealers are advised not to use any factory new connecting rod assemblies that are found in the kits or assemblies prior to examination. Refer to Table 1.

Table 1

Service kit, Piston Pack, and Rod Assembly Part Numbers That May Contain the Defective New Connecting Rod Assemblies

8N-1721 20R-1439 20R-1474

0R-1696 20R-1428 20R-1660

0R-1697 0R-9206 20R-1442

0R-3043 20R-1462 20R-1482

10R-3637 20R-1455 20R-1483

10R-9259 20R-1477 20R-1451

0R-1694 20R-1472 20R-1450

0R-4284 20R-1448 20R-1445

0R-1695 20R-1446 20R-1443

0R-4635 20R-1468 20R-1426

0R-4488 20R-1466 20R-1423

0R-4506 20R-1441 0R-2078

0R-3044 20R-1437 0R-3258

0R-2080 20R-1435 20R-1665

0R-3259 20R-1434 20R-1663

0R-3612 20R-1429 20R-1675

0R-3610 20R-1424 0R-3661

10R-6152 0R-2557 0R-1692

20R-1673 0R-2079 0R-1693

20R-1664 20R-1341 0R-3660

0R-4949 0R-2555 0R-3662

0R-9205 0R-3613 20R-1127

0R-2556 0R-4956 8N-1984

0R-3706 0R-2554

10R-1851 0R-4948

10R-1636 10R-0889

10R-1840 0R-3611

0R-2077 10R-7253

20R-1454 0R-7444 When an engine failure occurs due to the connecting rod assembly, dealers are asked to contact the Dealer Solution Network (DSN) Tier 2 core engine service engineer at Mossville Engine Center (MEC) to expedite support to the customer.To support field repairs and rebuilds, dealers are advised to inspect the manufacture date on any 3304, G3304, 3306, or G3306 engine with the 8N-1984 Connecting Rod , the 8N-1721 Connecting Rod , the 0R-0914 Connecting Rod , and the 0R-0915 Connecting Rod , used to perform repairs. If the manufacture date is within the suspect date range, do not use the part. Parts stocking service letters will be released soon to address suspect material in dealer inventories. Markings on the Suspect 8N-1984 Connecting Rod and the 8N-1721 Connecting Rod

Illustration 1 g03342875

(1