Information injection-pump assembly

BOSCH

9 400 612 358

9400612358

ZEXEL

101405-9240

1014059240

NISSAN-DIESEL

16790NA000

16790na000

Rating:

Service parts 101405-9240 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1660090105

12.

Open Pre:MPa(Kqf/cm2)

18.1(185)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 612 358

9400612358

ZEXEL

101405-9240

1014059240

NISSAN-DIESEL

16790NA000

16790na000

Zexel num

Bosch num

Firm num

Name

101405-9240

9 400 612 358

16790NA000 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

BD30T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

BD30T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

78.5

77.5

79.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

76

76

Boost pressure

mmHg

570

570

Injection quantity adjustment_02

Adjusting point

C

Rack position

8.5+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

12

10

14

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

10.8++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

70

70

80

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

900

900

900

Rack position

R1-1

Boost pressure

kPa

17.3

12

22.6

Boost pressure

mmHg

130

90

170

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Rack position

R1(10.6)

Boost pressure

kPa

66.7

64

69.4

Boost pressure

mmHg

500

480

520

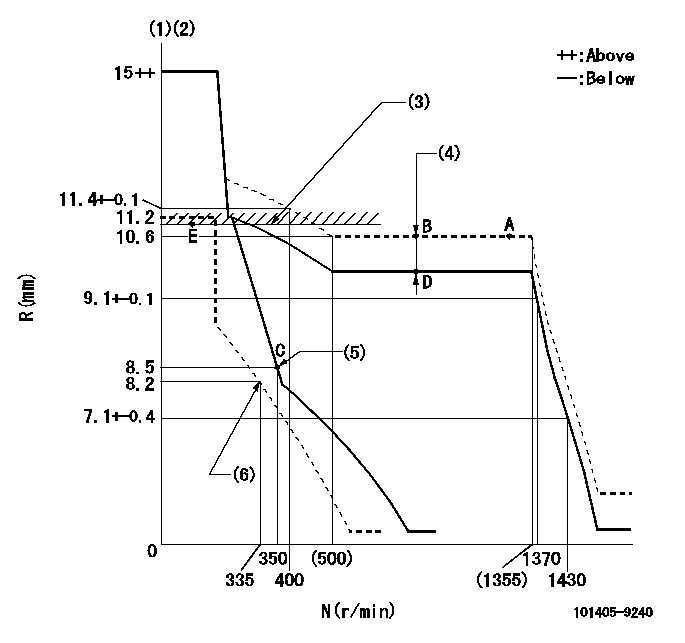

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

(5)Main spring setting

(6)Set idle sub-spring

----------

K=11 BCL=1+-0.1mm

----------

----------

K=11 BCL=1+-0.1mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=28deg+-5deg b=20deg+-5deg

----------

----------

a=28deg+-5deg b=20deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=32deg+-5deg b=50deg+-5deg

----------

----------

a=32deg+-5deg b=50deg+-5deg

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Maximum no-load speed (r/min)

LABEL9:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)At high idle rack position L

----------

L=7.1mm

----------

a1=A a2=B a3=C a4=- r1=1100r/min r2=1100r/min r3=1100r/min r4=- Q1=- Q2=78.5+-1mm3/st Q3=- Q4=- c1=- c2=+-3.5% c3=- c4=- a5=26 a6=25 a7=24 a8=23 a9=22 a10=21 a11=20 a12=19 a13=- a14=- a15=- r5=1300r/min r6=1250r/min r7=1200r/min r8=1150r/min r9=1100r/min r10=1050r/min r11=1000r/min r12=950r/min r13=- r14=- r15=- R5=1395+-32r/min R6=1340+-31r/min R7=1290+-30r/min R8=1235+-28r/min R9=1180+-27r/min R10=1130+-26r/min R11=1075+-25r/min R12=1020+-23r/min R13=- R14=- R15=-

----------

L=7.1mm

----------

a1=A a2=B a3=C a4=- r1=1100r/min r2=1100r/min r3=1100r/min r4=- Q1=- Q2=78.5+-1mm3/st Q3=- Q4=- c1=- c2=+-3.5% c3=- c4=- a5=26 a6=25 a7=24 a8=23 a9=22 a10=21 a11=20 a12=19 a13=- a14=- a15=- r5=1300r/min r6=1250r/min r7=1200r/min r8=1150r/min r9=1100r/min r10=1050r/min r11=1000r/min r12=950r/min r13=- r14=- r15=- R5=1395+-32r/min R6=1340+-31r/min R7=1290+-30r/min R8=1235+-28r/min R9=1180+-27r/min R10=1130+-26r/min R11=1075+-25r/min R12=1020+-23r/min R13=- R14=- R15=-

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'ZZ' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(100deg)

----------

aa=10deg

----------

a=(100deg)

Information:

Engine Performance

Poor vehicle performance is traditionally believed to be the result of a lack (or loss) of engine performance, when in fact the engine is only one of numerous factors that influence the overall performance of a vehicle. The previous section on fuel economy describes the factors that determine the power demand on an engine. The engine has no control over the demand made upon it by the vehicle or the operator.A vehicle that requires 225 hp (168 kW) to operate at 55 mph (88 km/h) will get worse fuel economy than a vehicle that requires only 175 hp (130 kW).These same factors also affect the amount of power available to perform additional work such as climb a grade or pass another vehicle. With a 310 hp (231 kW) engine, the first vehicle will have only 85 hp (63 kW) available to perform additional work compared to 135 hp (100 kW) on the second vehicle (mentioned above).If you feel you have a vehicle performance problem, first consider the impact of vehicle efficiency and operating characteristics (vehicle speed, design, etc.), on power demand before questioning engine performance. In the case of poor fuel economy, the engine is not likely to be the cause without the presence of excessive exhaust smoke and/or a significant loss of power.If you feel you have a valid engine performance problem, contact an authorized Caterpillar dealer for assistance. If your engine is under warranty, then the Caterpillar warranty or extended service coverage will cover the cost of resolving a valid engine performance deficiency.However, if the engine is not found at fault, all costs incurred will be the responsibility of the owner.

Adjustment of the fuel system outside Caterpillar specified limits will not improve fuel efficiency and can result in damage to the engine.

Performance Analysis Report (PAR)

PAR complements a good preventive maintenance program and Caterpillar recommends a regularly scheduled PAR analysis to monitor the condition and maintenance requirements of your engine and to ensure your engine is operating at peak efficiency.Potential problems can be identified early, thus preventing unnecessary repair costs and unscheduled downtime. Consult your Caterpillar dealer for complete information and assistance in establishing a PAR program for your engine.PAR reflects the results of various tests normally conducted by your Caterpillar dealer for the purpose of: * confirming your engine is operating efficiently and within specification.* identifying potential problems.* determining components or systems that should be adjusted, replaced, etc.Approximately 80 to 85% of your truck engine's operation and maintenance cost is the cost of the fuel. Therefore, substantial cost reductions can be achieved by keeping your engine operating at peak efficiency. The fuel economy and performance of the engine is affected by the truck specifications, how it is operated and the condition of the engine. Each plays an important part in minimizing your overall owning and operating cost.Caterpillar has an exclusive Performance Analysis Report (PAR) Program that can help you keep the engine portion of this equation up to PAR. The PAR Program uses a chassis

Poor vehicle performance is traditionally believed to be the result of a lack (or loss) of engine performance, when in fact the engine is only one of numerous factors that influence the overall performance of a vehicle. The previous section on fuel economy describes the factors that determine the power demand on an engine. The engine has no control over the demand made upon it by the vehicle or the operator.A vehicle that requires 225 hp (168 kW) to operate at 55 mph (88 km/h) will get worse fuel economy than a vehicle that requires only 175 hp (130 kW).These same factors also affect the amount of power available to perform additional work such as climb a grade or pass another vehicle. With a 310 hp (231 kW) engine, the first vehicle will have only 85 hp (63 kW) available to perform additional work compared to 135 hp (100 kW) on the second vehicle (mentioned above).If you feel you have a vehicle performance problem, first consider the impact of vehicle efficiency and operating characteristics (vehicle speed, design, etc.), on power demand before questioning engine performance. In the case of poor fuel economy, the engine is not likely to be the cause without the presence of excessive exhaust smoke and/or a significant loss of power.If you feel you have a valid engine performance problem, contact an authorized Caterpillar dealer for assistance. If your engine is under warranty, then the Caterpillar warranty or extended service coverage will cover the cost of resolving a valid engine performance deficiency.However, if the engine is not found at fault, all costs incurred will be the responsibility of the owner.

Adjustment of the fuel system outside Caterpillar specified limits will not improve fuel efficiency and can result in damage to the engine.

Performance Analysis Report (PAR)

PAR complements a good preventive maintenance program and Caterpillar recommends a regularly scheduled PAR analysis to monitor the condition and maintenance requirements of your engine and to ensure your engine is operating at peak efficiency.Potential problems can be identified early, thus preventing unnecessary repair costs and unscheduled downtime. Consult your Caterpillar dealer for complete information and assistance in establishing a PAR program for your engine.PAR reflects the results of various tests normally conducted by your Caterpillar dealer for the purpose of: * confirming your engine is operating efficiently and within specification.* identifying potential problems.* determining components or systems that should be adjusted, replaced, etc.Approximately 80 to 85% of your truck engine's operation and maintenance cost is the cost of the fuel. Therefore, substantial cost reductions can be achieved by keeping your engine operating at peak efficiency. The fuel economy and performance of the engine is affected by the truck specifications, how it is operated and the condition of the engine. Each plays an important part in minimizing your overall owning and operating cost.Caterpillar has an exclusive Performance Analysis Report (PAR) Program that can help you keep the engine portion of this equation up to PAR. The PAR Program uses a chassis

Have questions with 101405-9240?

Group cross 101405-9240 ZEXEL

Yanmar

Nissan-Diesel

101405-9240

9 400 612 358

16790NA000

INJECTION-PUMP ASSEMBLY

BD30T

BD30T