Information injection-pump assembly

BOSCH

9 400 613 181

9400613181

ZEXEL

101405-9232

1014059232

YANMAR

12991651001

12991651001

Rating:

Service parts 101405-9232 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 181

9400613181

ZEXEL

101405-9232

1014059232

YANMAR

12991651001

12991651001

Zexel num

Bosch num

Firm num

Name

101405-9232

9 400 613 181

12991651001 YANMAR

INJECTION-PUMP ASSEMBLY

4TNE94 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4TNE94 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

9

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

44.7

43.7

45.7

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.8+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

13

12

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

9.5++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

60

70

Fixing the lever

*

Rack limit

*

Test data Ex:

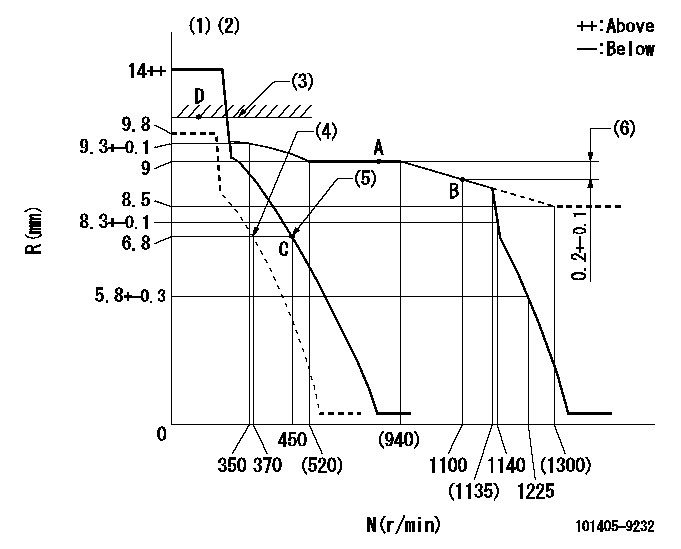

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

----------

K=10 N1=1100r/min N2=800r/min

----------

----------

K=10 N1=1100r/min N2=800r/min

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=5deg+-5deg b=22deg+-5deg

----------

----------

a=5deg+-5deg b=22deg+-5deg

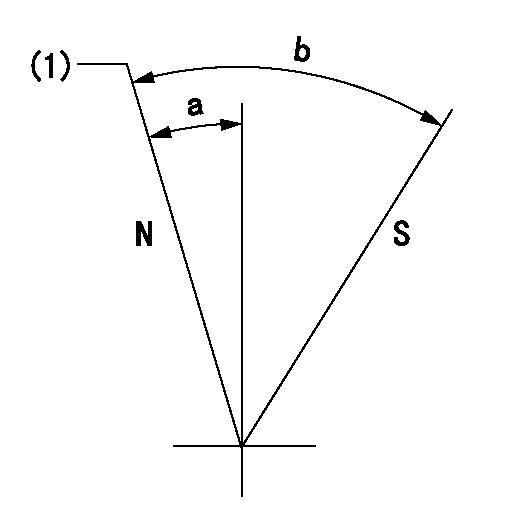

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=10deg+-5deg b=53deg+-5deg

----------

----------

a=10deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Downhill

When cresting a hill, the decision of whether to use power or not on the downside of the hill must be made. Best fuel economy results from using minimum power to get back to speed after climbing a grade. However, care must be taken not to allow the engine to overspeed. This engine should not exceed 2300 rpm. The PEEC cruise control may use full engine power to return the truck to the cruise set speed if the engine was unable to maintain the set speed while climbing a hill. The cruise control should be turned off before cresting the top of a hill and light throttle used to regain vehicle speed on a downhill to minimize fuel consumption.If equipped with an exhaust brake, the engine should not exceed maximum braking rpm. Refer to "Auxiliary Exhaust Brakes" section of this manual.Saving Fuel On Hills

Rolling hills provide a great opportunity to reduce fuel. Avoid downshifting on small hills. If a hill can be topped without downshifting, even if the engine lugs to the peak torque rpm (1100 - 1200), the truck should not be downshifted.On long grades that require one or more downshifts, let the PEEC engine lug back to the peak torque rpm. If road speed stabilizes with the engine running at or above peak torque rpm, remain in that gear. When going down hill, use gravity instead of engine power to regain vehicle speed.Long steep down grades should be anticipated. Vehicle speed should be reduced before cresting the top of a hill and proceeding down a long steep grade. The way to achieve maximum fuel efficiency, is to minimize the amount of braking that is used to maintain a safe vehicle speed.The engine's ability to hold the truck back increases with engine speed. A gear should be selected that runs the engine near the high engine rpm limit for long steep hills when braking is required.Speed reductions and future stops should be anticipated ahead of time to save fuel. Downshifts should be avoided and the amount of braking minimized to improve fuel consumption.Cruising Speed

It's a simple fact that the faster a vehicle is driven the more fuel it will consume. A few miles per hour (km/h) can make a significant difference in fuel economy.Increasing cruising speed from 55 to 65 mph (88 to 104 km/h) will increase fuel consumption of a typical class 8 truck approximately 1.0 mpg (0.4 km/L). A practice of driving faster to increase stop time makes those stops very expensive.Cruising is the most common operating condition for most trucks and therefore, provides the greatest opportunity to benefit from operation in the most fuel efficient rpm range of the engine. A significant improvement in fuel economy can be realized by operating the truck in a gear that will keep the engine between 1400 and 1600 rpm.The PEEC can be programmed to limit vehicle speed and encourage operation in the highest gear during a cruising condition for optimum fuel economy.Cruise Control (CC)

The PEEC engine can

When cresting a hill, the decision of whether to use power or not on the downside of the hill must be made. Best fuel economy results from using minimum power to get back to speed after climbing a grade. However, care must be taken not to allow the engine to overspeed. This engine should not exceed 2300 rpm. The PEEC cruise control may use full engine power to return the truck to the cruise set speed if the engine was unable to maintain the set speed while climbing a hill. The cruise control should be turned off before cresting the top of a hill and light throttle used to regain vehicle speed on a downhill to minimize fuel consumption.If equipped with an exhaust brake, the engine should not exceed maximum braking rpm. Refer to "Auxiliary Exhaust Brakes" section of this manual.Saving Fuel On Hills

Rolling hills provide a great opportunity to reduce fuel. Avoid downshifting on small hills. If a hill can be topped without downshifting, even if the engine lugs to the peak torque rpm (1100 - 1200), the truck should not be downshifted.On long grades that require one or more downshifts, let the PEEC engine lug back to the peak torque rpm. If road speed stabilizes with the engine running at or above peak torque rpm, remain in that gear. When going down hill, use gravity instead of engine power to regain vehicle speed.Long steep down grades should be anticipated. Vehicle speed should be reduced before cresting the top of a hill and proceeding down a long steep grade. The way to achieve maximum fuel efficiency, is to minimize the amount of braking that is used to maintain a safe vehicle speed.The engine's ability to hold the truck back increases with engine speed. A gear should be selected that runs the engine near the high engine rpm limit for long steep hills when braking is required.Speed reductions and future stops should be anticipated ahead of time to save fuel. Downshifts should be avoided and the amount of braking minimized to improve fuel consumption.Cruising Speed

It's a simple fact that the faster a vehicle is driven the more fuel it will consume. A few miles per hour (km/h) can make a significant difference in fuel economy.Increasing cruising speed from 55 to 65 mph (88 to 104 km/h) will increase fuel consumption of a typical class 8 truck approximately 1.0 mpg (0.4 km/L). A practice of driving faster to increase stop time makes those stops very expensive.Cruising is the most common operating condition for most trucks and therefore, provides the greatest opportunity to benefit from operation in the most fuel efficient rpm range of the engine. A significant improvement in fuel economy can be realized by operating the truck in a gear that will keep the engine between 1400 and 1600 rpm.The PEEC can be programmed to limit vehicle speed and encourage operation in the highest gear during a cruising condition for optimum fuel economy.Cruise Control (CC)

The PEEC engine can

Have questions with 101405-9232?

Group cross 101405-9232 ZEXEL

Yanmar

101405-9232

9 400 613 181

12991651001

INJECTION-PUMP ASSEMBLY

4TNE94

4TNE94