Information injection-pump assembly

BOSCH

9 400 612 826

9400612826

ZEXEL

101405-9210

1014059210

YANMAR

12998051010

12998051010

Rating:

Service parts 101405-9210 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 612 826

9400612826

ZEXEL

101405-9210

1014059210

YANMAR

12998051010

12998051010

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.2

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

66

65

67

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.6+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

13

12

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

11.2++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85

80

90

Fixing the lever

*

Rack limit

*

Test data Ex:

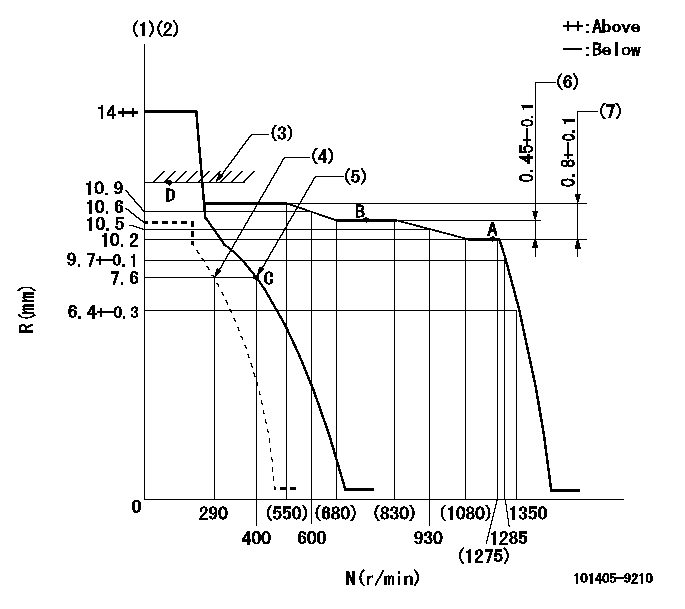

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

(7)Rack difference between N = N3 and N = N4

----------

K=12 N1=1250r/min N2=800r/min N3=1250r/min N4=450r/min

----------

----------

K=12 N1=1250r/min N2=800r/min N3=1250r/min N4=450r/min

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=16deg+-5deg b=30deg+-5deg

----------

----------

a=16deg+-5deg b=30deg+-5deg

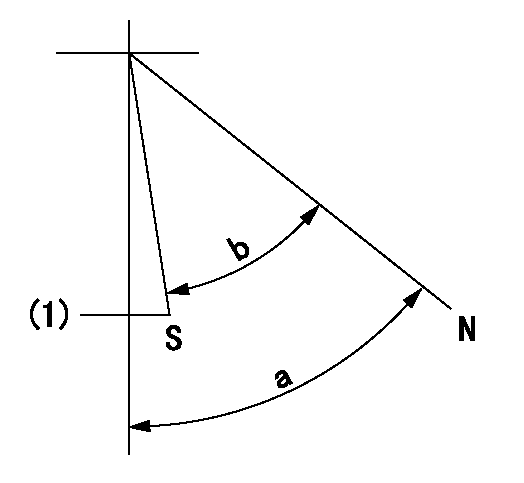

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal stop

----------

----------

a=58deg+-5deg b=53deg+-5deg

----------

----------

a=58deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

New Dipsticks With Full Range Readings

The new rear sump and front sump dipsticks are used with their respective oil pans. These oil pans are used in truck applications with set-back axles.The new dipsticks are different because they have a FULL RANGE zone versus other dipsticks that have the traditional FULL mark. These dipsticks are used for truck applications with various angles and slants of engine installation (angle = front to back tilt, slant = sideways tilt).Calibration

Use the following procedure to calibrate FULL RANGE dipsticks. A convenient time to calibrate the dipstick is at the first oil change.Refer to the PM Level 1 of the Maintenance Management Schedule of this publication for the proper oil change interval.To verify the "ADD" mark and establish the actual "FULL" mark, use the following procedure: Truck must be parked on a level surface.1. Operate the engine until it reaches normal operating temperature.2. Stop the engine. Drain the oil and change the oil filter.3. Fill the crankcase with 32 U.S. quarts (30.3 liters) of oil. Brakesaver models require 36 quarts (34 L). Remote mounted or auxiliary filters require additional oil. For all information pertaining to auxiliary oil filters, refer to the OEM or manufacturer's instructions.4. Allow the oil to drain back to the sump for a minimum of five minutes.5. Remove the dipstick. The oil level should be at the ADD mark. If it is not, mark the actual level on the dipstick. This is now the correct ADD mark.6. Add an additional 4 U.S. quarts (3.8 liters) of oil to the sump. Allow enough time for the oil to drain into the sump. Again, check the level on the dipstick.7. This is the correct FULL mark in the FULL RANGE zone on the dipstick. If it is not, mark the new FULL level on the dipstick. Remote mounted or auxiliary filters require additional oil also. For all information pertaining to auxiliary oil filters, refer to the OEM or manufacturer's instructions.8. Start the engine and operate until it reaches normal operating temperature. Stop the engine.9. Allow the oil to drain back to the sump for a minimum of 10 minutes.10. Remove the dipstick. The oil level should be near the FULL mark. If it is not, add oil until the level reaches the FULL mark on the dipstick.This procedure is correct for use with either the non-spacer plate oil pan or the spacer plate oil pan. Sump capacities and oil levels are the same for each oil pan.Any FULL RANGE dipstick for the 3406B Truck engine can be calibrated using this procedure.

The new rear sump and front sump dipsticks are used with their respective oil pans. These oil pans are used in truck applications with set-back axles.The new dipsticks are different because they have a FULL RANGE zone versus other dipsticks that have the traditional FULL mark. These dipsticks are used for truck applications with various angles and slants of engine installation (angle = front to back tilt, slant = sideways tilt).Calibration

Use the following procedure to calibrate FULL RANGE dipsticks. A convenient time to calibrate the dipstick is at the first oil change.Refer to the PM Level 1 of the Maintenance Management Schedule of this publication for the proper oil change interval.To verify the "ADD" mark and establish the actual "FULL" mark, use the following procedure: Truck must be parked on a level surface.1. Operate the engine until it reaches normal operating temperature.2. Stop the engine. Drain the oil and change the oil filter.3. Fill the crankcase with 32 U.S. quarts (30.3 liters) of oil. Brakesaver models require 36 quarts (34 L). Remote mounted or auxiliary filters require additional oil. For all information pertaining to auxiliary oil filters, refer to the OEM or manufacturer's instructions.4. Allow the oil to drain back to the sump for a minimum of five minutes.5. Remove the dipstick. The oil level should be at the ADD mark. If it is not, mark the actual level on the dipstick. This is now the correct ADD mark.6. Add an additional 4 U.S. quarts (3.8 liters) of oil to the sump. Allow enough time for the oil to drain into the sump. Again, check the level on the dipstick.7. This is the correct FULL mark in the FULL RANGE zone on the dipstick. If it is not, mark the new FULL level on the dipstick. Remote mounted or auxiliary filters require additional oil also. For all information pertaining to auxiliary oil filters, refer to the OEM or manufacturer's instructions.8. Start the engine and operate until it reaches normal operating temperature. Stop the engine.9. Allow the oil to drain back to the sump for a minimum of 10 minutes.10. Remove the dipstick. The oil level should be near the FULL mark. If it is not, add oil until the level reaches the FULL mark on the dipstick.This procedure is correct for use with either the non-spacer plate oil pan or the spacer plate oil pan. Sump capacities and oil levels are the same for each oil pan.Any FULL RANGE dipstick for the 3406B Truck engine can be calibrated using this procedure.