Information injection-pump assembly

BOSCH

9 400 612 524

9400612524

ZEXEL

101405-9170

1014059170

YANMAR

12991551030

12991551030

Rating:

Service parts 101405-9170 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 612 524

9400612524

ZEXEL

101405-9170

1014059170

YANMAR

12991551030

12991551030

Zexel num

Bosch num

Firm num

Name

9 400 612 524

12991551030 YANMAR

INJECTION-PUMP ASSEMBLY

4TNE94 * K 14BC PE4A,5A, PE

4TNE94 * K 14BC PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

48.3

47.3

49.3

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

13

12

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

9.4++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

60

70

Fixing the lever

*

Rack limit

*

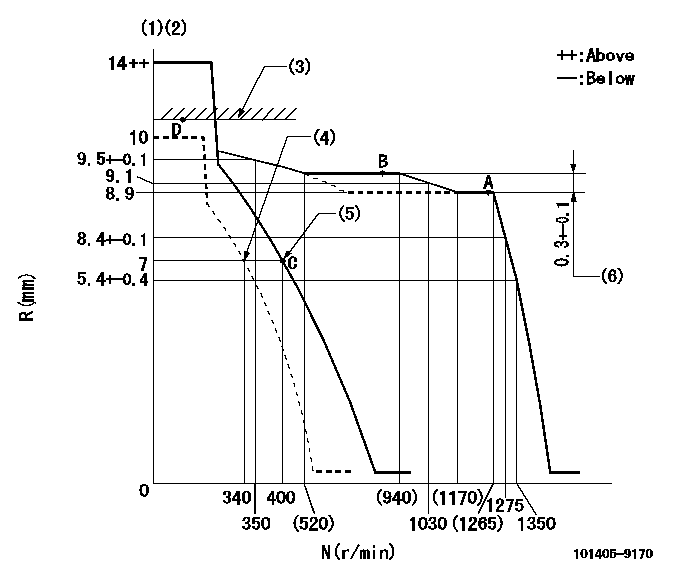

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

----------

K=8 N1=1250r/min N2=800r/min

----------

----------

K=8 N1=1250r/min N2=800r/min

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=7deg+-5deg b=26deg+-5deg

----------

----------

a=7deg+-5deg b=26deg+-5deg

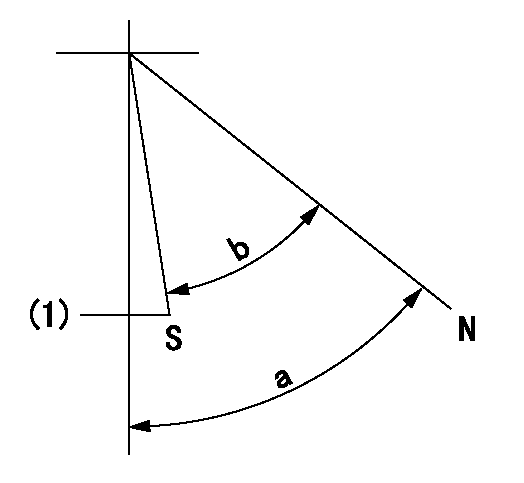

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal stop

----------

----------

a=58deg+-5deg b=53deg+-5deg

----------

----------

a=58deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Extended Warranties & Service Contracts

A wide variety of protection plans are available for Caterpillar 3306B Truck Engines. Consult your local Caterpillar Engine Service dealer for information on the plan shown below which is tailored to fit your needs.* ESC-Extended Service Coverage* OPT-Overhaul Protection for Trucks* Remanufactured Extended Coverage* TOPP-Truck Owner Protection PlanContact your local Caterpillar Engine Service dealer for more detailed information on specific programs and coverages available, or call 1-800-CALL CAT, and ask for the Engine Protection Plan Sales Manager.U.S.A. Emergency Service Only

When a problem arises concerning the sale, operation or service of your engine, it will normally be handled by the distributor or dealer in your area. The service facility nearest you can be located twenty-four hours a day by calling the appropriate phone numbers listed below.In U.S. (except Illinois, Alaska and Hawaii) Phone 1 (800) 447-4986.In the States of Illinois, Alaska and Hawaii Phone (309) 673-3252 (collect).Your satisfaction is a primary concern to Caterpillar, its distributors and their dealers. To assure your complete satisfaction, we suggest the following steps be followed should you have a problem that has not been handled to your satisfaction.Step One

Discuss your problem with a member of management from the distributorship or dealership. If your problem originates with a dealer, explain the matter to a management member of the distributorship with whom the dealer has his parts and service agreement.Step Two

When it appears that your problem cannot be readily resolved at the distributor level without additional assistance, use the above telephone numbers and ask to talk to a Field Service Coordinator.Step Three

If you are still not satisfied, present the engine matter in writing to:Caterpillar Inc.

Manager, Truck Engine Business

Peoria, Illinois 61629

When contacting the Manager, Truck Engine Business, please keep in mind that ultimately your problem will likely be resolved at the distributorship or dealership using their facilities, equipment, and personnel. Therefore, it is suggested that you follow the above steps in sequence when experiencing a problem.

A wide variety of protection plans are available for Caterpillar 3306B Truck Engines. Consult your local Caterpillar Engine Service dealer for information on the plan shown below which is tailored to fit your needs.* ESC-Extended Service Coverage* OPT-Overhaul Protection for Trucks* Remanufactured Extended Coverage* TOPP-Truck Owner Protection PlanContact your local Caterpillar Engine Service dealer for more detailed information on specific programs and coverages available, or call 1-800-CALL CAT, and ask for the Engine Protection Plan Sales Manager.U.S.A. Emergency Service Only

When a problem arises concerning the sale, operation or service of your engine, it will normally be handled by the distributor or dealer in your area. The service facility nearest you can be located twenty-four hours a day by calling the appropriate phone numbers listed below.In U.S. (except Illinois, Alaska and Hawaii) Phone 1 (800) 447-4986.In the States of Illinois, Alaska and Hawaii Phone (309) 673-3252 (collect).Your satisfaction is a primary concern to Caterpillar, its distributors and their dealers. To assure your complete satisfaction, we suggest the following steps be followed should you have a problem that has not been handled to your satisfaction.Step One

Discuss your problem with a member of management from the distributorship or dealership. If your problem originates with a dealer, explain the matter to a management member of the distributorship with whom the dealer has his parts and service agreement.Step Two

When it appears that your problem cannot be readily resolved at the distributor level without additional assistance, use the above telephone numbers and ask to talk to a Field Service Coordinator.Step Three

If you are still not satisfied, present the engine matter in writing to:Caterpillar Inc.

Manager, Truck Engine Business

Peoria, Illinois 61629

When contacting the Manager, Truck Engine Business, please keep in mind that ultimately your problem will likely be resolved at the distributorship or dealership using their facilities, equipment, and personnel. Therefore, it is suggested that you follow the above steps in sequence when experiencing a problem.