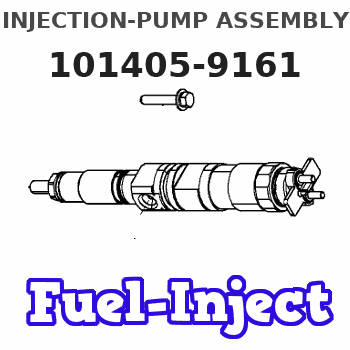

Information injection-pump assembly

BOSCH

9 400 614 063

9400614063

ZEXEL

101405-9161

1014059161

YANMAR

12995551061

12995551061

Rating:

Service parts 101405-9161 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

Zexel num

Bosch num

Firm num

Name

101405-9161

9 400 614 063

12995551061 YANMAR

INJECTION-PUMP ASSEMBLY

4TNE98 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4TNE98 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Information:

Maintenance Recommendations

Caterpillar Inc. truck engines are certified by the United States Environmental Protection Agency (EPA) to comply with smoke and gaseous emission standards prescribed by Federal laws at the time of manufacture.Efficiency of emission control and engine performance depends on adherence to proper operation and maintenance recommendations AND use of recommended fuels and lubricating oils. It is recommended that major adjustments and repair be made by your authorized Caterpillar dealer.Various chemical fuel additives claiming to reduce visible smoke are available commercially. Although additives have been used by individuals to solve some isolated smoke problems in the field, they are not recommended for general use. Federal smoke regulations require that engines be certified without smoke depressants.The corrective steps taken immediately on discovery of worn parts, which may affect emission levels, will help assure proper operation of emission control systems. The use of genuine Caterpillar parts is recommended. Suppliers of non-Caterpillar parts must assure the owner that the use of such parts will not adversely affect emission levels.Regular maintenance intervals, along with special emphasis on the following items, are necessary to keep exhaust emissions within acceptable limits for the useful life of the engine. Refer to the Maintenance Management Schedule and Maintenance Section of this manual for details. If the engine is operating under severe conditions, adjust the maintenance schedule accordingly. See your authorized Caterpillar dealer to help analyze your specific application, operating environment and maintenance schedule adjustments.The following is an explanation of maintenance for emission-related components. See the Maintenance Management Schedule for the specific interval for the following items. FUEL INJECTION NOZZLES - Damaged fuel nozzles will normally cause the engine to misfire, run rough and smoke. Test and replace if necessary as recommended in the Maintenance Management Schedule. Fuel nozzles can be tested by an authorized Caterpillar truck engine dealer. TURBOCHARGER - Check for any unusual sound or vibration in the turbocharger. Inspect inlet and exhaust piping and connections. Check bearing condition and perform maintenance as described in the Maintenance Management Schedule.Owner is encouraged to keep adequate maintenance records, but the absence of such, in and of itself, will not invalidate the warranty.The vehicle owner may perform routine maintenance, repairs and other non warranty work or have it done at any repair facility. Such non warranty work need not be performed at a designated warranty station in order for the warranty to remain in force.Customer Assistance

Caterpillar Inc. aims to ensure that the Emission Control Systems warranty is properly administered. In the event that you do not receive the warranty service to which you believe you are entitled under the Emission Control Systems Warranty, call or write:Caterpillar Inc.

Manager, Truck Engine Business

Peoria, Illinois 61629

Ph. (309) 578-6288

Authorized dealers are recommended for major maintenance and repair work as they are staffed with trained personnel, proper tools and are aware of the latest maintenance methods and procedures. Owners and others who desire to perform their own work should purchase a Service Manual and obtain current service information from their Caterpillar dealer.For information regarding

Caterpillar Inc. truck engines are certified by the United States Environmental Protection Agency (EPA) to comply with smoke and gaseous emission standards prescribed by Federal laws at the time of manufacture.Efficiency of emission control and engine performance depends on adherence to proper operation and maintenance recommendations AND use of recommended fuels and lubricating oils. It is recommended that major adjustments and repair be made by your authorized Caterpillar dealer.Various chemical fuel additives claiming to reduce visible smoke are available commercially. Although additives have been used by individuals to solve some isolated smoke problems in the field, they are not recommended for general use. Federal smoke regulations require that engines be certified without smoke depressants.The corrective steps taken immediately on discovery of worn parts, which may affect emission levels, will help assure proper operation of emission control systems. The use of genuine Caterpillar parts is recommended. Suppliers of non-Caterpillar parts must assure the owner that the use of such parts will not adversely affect emission levels.Regular maintenance intervals, along with special emphasis on the following items, are necessary to keep exhaust emissions within acceptable limits for the useful life of the engine. Refer to the Maintenance Management Schedule and Maintenance Section of this manual for details. If the engine is operating under severe conditions, adjust the maintenance schedule accordingly. See your authorized Caterpillar dealer to help analyze your specific application, operating environment and maintenance schedule adjustments.The following is an explanation of maintenance for emission-related components. See the Maintenance Management Schedule for the specific interval for the following items. FUEL INJECTION NOZZLES - Damaged fuel nozzles will normally cause the engine to misfire, run rough and smoke. Test and replace if necessary as recommended in the Maintenance Management Schedule. Fuel nozzles can be tested by an authorized Caterpillar truck engine dealer. TURBOCHARGER - Check for any unusual sound or vibration in the turbocharger. Inspect inlet and exhaust piping and connections. Check bearing condition and perform maintenance as described in the Maintenance Management Schedule.Owner is encouraged to keep adequate maintenance records, but the absence of such, in and of itself, will not invalidate the warranty.The vehicle owner may perform routine maintenance, repairs and other non warranty work or have it done at any repair facility. Such non warranty work need not be performed at a designated warranty station in order for the warranty to remain in force.Customer Assistance

Caterpillar Inc. aims to ensure that the Emission Control Systems warranty is properly administered. In the event that you do not receive the warranty service to which you believe you are entitled under the Emission Control Systems Warranty, call or write:Caterpillar Inc.

Manager, Truck Engine Business

Peoria, Illinois 61629

Ph. (309) 578-6288

Authorized dealers are recommended for major maintenance and repair work as they are staffed with trained personnel, proper tools and are aware of the latest maintenance methods and procedures. Owners and others who desire to perform their own work should purchase a Service Manual and obtain current service information from their Caterpillar dealer.For information regarding

Have questions with 101405-9161?

Group cross 101405-9161 ZEXEL

Yanmar

Mitsubishi-Heav

Mitsubishi-Heav

Mitsubishi-Heav

Mitsubishi-Heav

Mitsubishi-Heav

Yanmar

101405-9161

9 400 614 063

12995551061

INJECTION-PUMP ASSEMBLY

4TNE98

4TNE98