Information injection-pump assembly

BOSCH

9 400 612 490

9400612490

ZEXEL

101405-9100

1014059100

YANMAR

12995551050

12995551050

Rating:

Service parts 101405-9100 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 612 490

9400612490

ZEXEL

101405-9100

1014059100

YANMAR

12995551050

12995551050

Zexel num

Bosch num

Firm num

Name

9 400 612 490

12995551050 YANMAR

INJECTION-PUMP ASSEMBLY

4TNE98 * K 14BC PE4A,5A, PE

4TNE98 * K 14BC PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

61

60

62

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

11.5

10.5

12.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

11.8++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

70

80

Fixing the lever

*

Rack limit

*

Test data Ex:

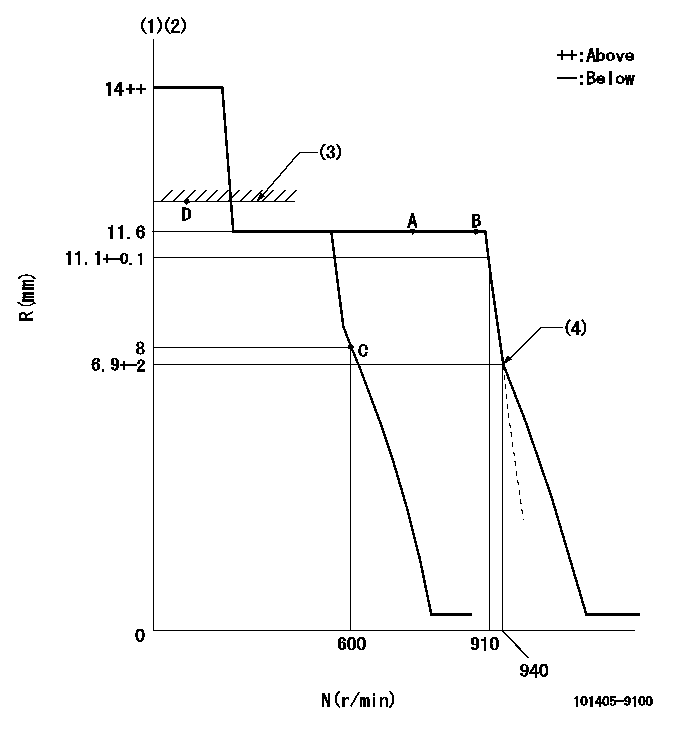

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Idle sub spring setting: L1.

----------

K=10 L1=6.9-0.5mm

----------

----------

K=10 L1=6.9-0.5mm

----------

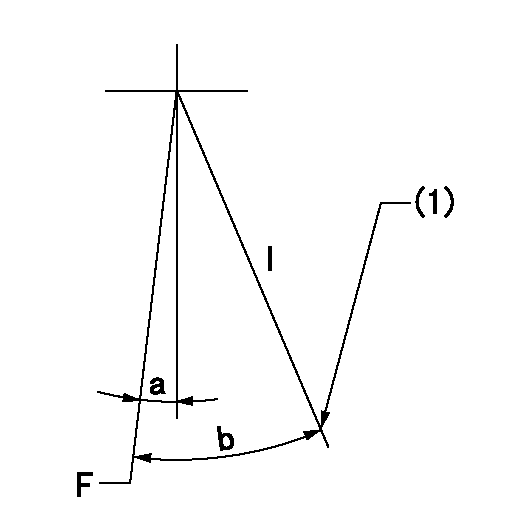

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(0deg)+-5deg b=(12deg)+-5deg

----------

----------

a=(0deg)+-5deg b=(12deg)+-5deg

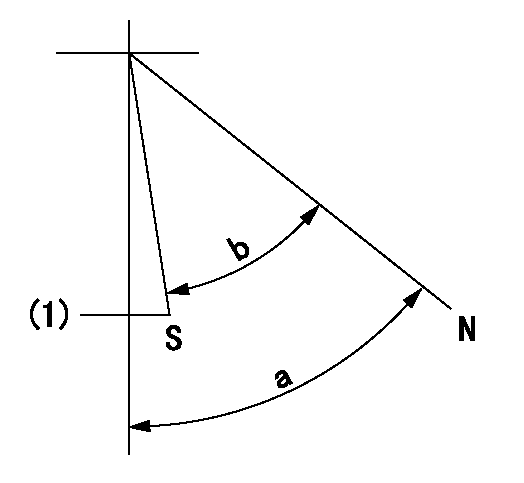

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal stop

----------

----------

a=58deg+-5deg b=53deg+-5deg

----------

----------

a=58deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Lubricant Information

Certain abbreviations follow S.A.E. J754 nomenclature and some classifications follow S.A.E. J183 abbreviations. The definitions other than Caterpillar's will be of assistance in purchasing lubricants. The recommended oil viscosities can be found in the Lubricant Viscosities chart in this publication.The grease is classified by the National Lubricating Grease Institute (NLGI) based on the ASTM D217-68 Worked Penetration characteristics which are given a defined consistency number.Engine Oil (EO)

Caterpillar has an oil formulation to provide maximum performance and life in your truck engine.* Cat Engine Oil (EO)Cat Engine Oil (EO) is a lubricant that meets the performance requirements of today' newer truck engines as well as meeting the needs of earlier built truck engines. This oil has sufficient TBN and sulfated ash level to be effective in operation.This lubricating oil also meets the industry standards for both diesel and gasoline engine requirements.* Cat Diesel Engine Oil (DEO)Cat Diesel Engine Oil (DEO) may be used for current truck engines also. DEO provides the required performance for 3406B truck engines, however, it does not meet the API CE performance.Alternate Oils

Failure to follow these recommendations for CE performance oils can cause shortened engine life due to carbon deposits or excessive wear.

If an oil other than Cat oil is to be used, the following oil specifications provide selection guidelines: * API specifications CE, CE/SF, or CE/SGOil with these specifications may require shortened oil change periods as determined by close monitoring of oil condition with Scheduled Oil Sampling (S O S) and infrared analysis.Additional Notes

The percentage of sulfur in the fuel will affect the engine oil recommendations. For fuel sulfur effects, the Infrared Analysis and the ASTM D2896 procedure can be used to evaluate the residual neutralization properties of an engine oil. The sulfur products formation depends on the fuel sulfur content, oil formulation, crankcase blowby, engine operating conditions and ambient temperature.The Caterpillar 20 times rule for TBN versus fuel sulfur is a general requirement, but it can be modified by used oil analysis. The effectiveness of an oil formulation will depend on the additive package. A balanced additive package oil of a lower TBN can be as effective in fuel sulfur neutralization and overall performance as some oils with higher TBN values which have additives just for increased TBN. The used oil analysis can show these results.Consult the EMA Lubricating Oils Data Book, form SEBU6310 for a listing of oil brands meeting the CE requirements.For more information on oil and fuel sulfur content, refer to "Oil and Your Engine," form SEBD0640.Always consult with your Caterpillar dealer for the latest lubrication recommendations.Anti-Seize Compound (ASC)

Use 5P3931 Anti-Seize Compound (ASC) or equivalent.Cat Lubricating Grease

Caterpillar has greases for all applications.* Cat Multipurpose Lithium Grease (MPGL) (non-extreme pressure)This NLGI No. 2 grade is recommended for light duty automotive type applications where a high temperature [up to 175°C (350°F)] is required. This grease offers excellent mechanical stability, high resistance to oxidation, good rust protection and excellent breakaway torque.If this grease is not available, use a similar multipurpose grease.* Cat

Certain abbreviations follow S.A.E. J754 nomenclature and some classifications follow S.A.E. J183 abbreviations. The definitions other than Caterpillar's will be of assistance in purchasing lubricants. The recommended oil viscosities can be found in the Lubricant Viscosities chart in this publication.The grease is classified by the National Lubricating Grease Institute (NLGI) based on the ASTM D217-68 Worked Penetration characteristics which are given a defined consistency number.Engine Oil (EO)

Caterpillar has an oil formulation to provide maximum performance and life in your truck engine.* Cat Engine Oil (EO)Cat Engine Oil (EO) is a lubricant that meets the performance requirements of today' newer truck engines as well as meeting the needs of earlier built truck engines. This oil has sufficient TBN and sulfated ash level to be effective in operation.This lubricating oil also meets the industry standards for both diesel and gasoline engine requirements.* Cat Diesel Engine Oil (DEO)Cat Diesel Engine Oil (DEO) may be used for current truck engines also. DEO provides the required performance for 3406B truck engines, however, it does not meet the API CE performance.Alternate Oils

Failure to follow these recommendations for CE performance oils can cause shortened engine life due to carbon deposits or excessive wear.

If an oil other than Cat oil is to be used, the following oil specifications provide selection guidelines: * API specifications CE, CE/SF, or CE/SGOil with these specifications may require shortened oil change periods as determined by close monitoring of oil condition with Scheduled Oil Sampling (S O S) and infrared analysis.Additional Notes

The percentage of sulfur in the fuel will affect the engine oil recommendations. For fuel sulfur effects, the Infrared Analysis and the ASTM D2896 procedure can be used to evaluate the residual neutralization properties of an engine oil. The sulfur products formation depends on the fuel sulfur content, oil formulation, crankcase blowby, engine operating conditions and ambient temperature.The Caterpillar 20 times rule for TBN versus fuel sulfur is a general requirement, but it can be modified by used oil analysis. The effectiveness of an oil formulation will depend on the additive package. A balanced additive package oil of a lower TBN can be as effective in fuel sulfur neutralization and overall performance as some oils with higher TBN values which have additives just for increased TBN. The used oil analysis can show these results.Consult the EMA Lubricating Oils Data Book, form SEBU6310 for a listing of oil brands meeting the CE requirements.For more information on oil and fuel sulfur content, refer to "Oil and Your Engine," form SEBD0640.Always consult with your Caterpillar dealer for the latest lubrication recommendations.Anti-Seize Compound (ASC)

Use 5P3931 Anti-Seize Compound (ASC) or equivalent.Cat Lubricating Grease

Caterpillar has greases for all applications.* Cat Multipurpose Lithium Grease (MPGL) (non-extreme pressure)This NLGI No. 2 grade is recommended for light duty automotive type applications where a high temperature [up to 175°C (350°F)] is required. This grease offers excellent mechanical stability, high resistance to oxidation, good rust protection and excellent breakaway torque.If this grease is not available, use a similar multipurpose grease.* Cat