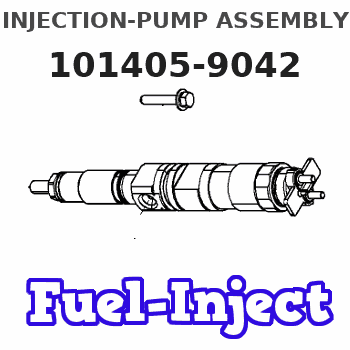

Information injection-pump assembly

BOSCH

9 400 612 821

9400612821

ZEXEL

101405-9042

1014059042

YANMAR

12995351120

12995351120

Rating:

Service parts 101405-9042 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

Zexel num

Bosch num

Firm num

Name

101405-9042

9 400 612 821

12995351120 YANMAR

INJECTION-PUMP ASSEMBLY

4TNE98 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4TNE98 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Information:

Exhaust brakes should not be used as a primary or service brake.

Auxiliary engine braking devices are approved for use on the 3406B Engine.Compression Brake

Operation (Jacobs Brake or Pacific Brake)

The Jacobs Engine Brake should not be used as a primary or service brake. Do not allow the engine to exceed 2300 rpm. However, engines equipped with a Jacobs Engine Brake should not normally be operated above 2100 rpm.

The Jacobs Engine Brake is an engine attachment that converts a diesel engine into an air compressor. Its function is to slow the vehicle and reduce brake wear.Operating Controls-Compression Brake

The Jacobs Engine Brake controls may include a dash mounted module or an ON/OFF switch and a three position switch with "Lo," "Med" and "Hi" depending on how many cylinders of braking desired.On some applications a multiposition switch is used to provide variable retarding capability. Operators should become familiar with the controls used on their vehicles. Refer to the OEM vehicle manual for the type of operating controls that your vehicle is equipped with.Since the Jacobs Engine Brake is most effective at rated engine rpm, gear selection is very important. Gearing down the vehicle, within the limits of rated engine rpm, makes the engine brake a more effective retarder. Maximum retarding occurs at higher engine rpm.For information on adjustment to Jacobs Brake slave piston lash, refer to PM Level 2-Engine Valve Lash. Refer to Jacobs Brake Troubleshooting Manual, Form SENR4251 for information regarding this auxiliary braking system.There are differences in exhaust braking devices from those with little or no leakage when activated to those with a great deal of leakage.Sliding Gate Type (Williams Blue Ox)

This type of exhaust brake allows minimal leakage and must have a relief orifice to limit the maximum exhaust manifold back pressure to 50 psi (345 kPa) at maximum engine braking rpm. Flapper Type (Pacific)

With this type of exhaust brake, there is usually leakage around the movable plate. To obtain 50 psi (345 kPa) or 70 psi (485 kPa) performance level braking, a small hole would likely be required. The maximum permissible exhaust back pressure at maximum engine braking rpm is measured at the 1/4 NPT hole in the exhaust manifold below the turbocharger.Refer to the April, 1988 "Truck Engine Application and Installation Guide," Form LEBT8121 for more information.Exhaust Brake Option-70 psi (485 kPa) (flapper or sliding gate type)

This auxiliary brake has been approved for use with 3406B Truck engines, but because of the higher exhaust back pressure of 70 psi (485 kPa), larger exhaust valve springs and associated parts must be used when installed.The recommended orifice size for this braking device is .688 in. (17.48 mm), and it applies to a maximum braking rpm of 2200 rpm. A smaller orifice and/or higher operating speed will cause excessive back pressure and may shorten valve train life.

Due to interference with the larger valve rotators, the 70 psi (485 kPa) type exhaust brake cannot be used in addition to compression type brakes to obtain additional braking capacity.

Refer to the Service Manual

Have questions with 101405-9042?

Group cross 101405-9042 ZEXEL

Yanmar

Yanmar

Yanmar

Dpico

Yanmar

101405-9042

9 400 612 821

12995351120

INJECTION-PUMP ASSEMBLY

4TNE98

4TNE98