Information injection-pump assembly

BOSCH

9 400 611 821

9400611821

ZEXEL

101405-9040

1014059040

Rating:

Service parts 101405-9040 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 821

9400611821

ZEXEL

101405-9040

1014059040

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.2

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

66

65

67

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.6+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

13

12

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85

80

90

Fixing the lever

*

Rack limit

*

Test data Ex:

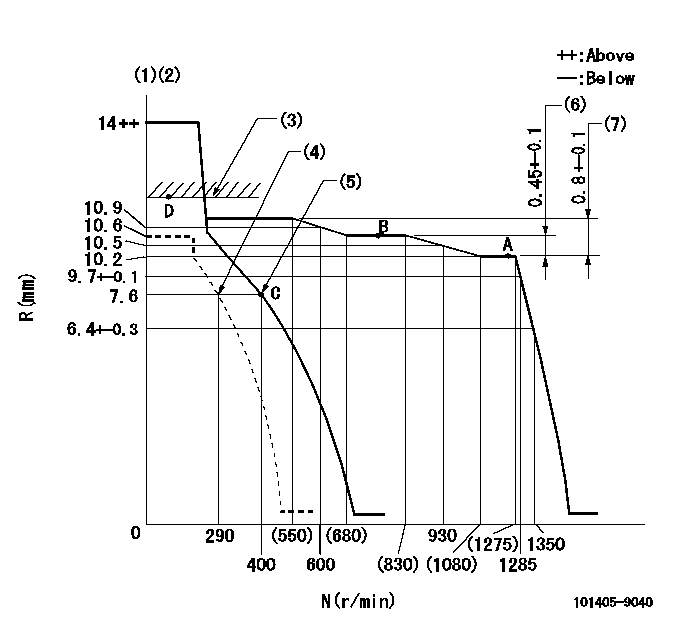

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

(7)Rack difference between N = N3 and N = N4

----------

K=12 N1=1250r/min N2=800r/min N3=1250r/min N4=450r/min

----------

----------

K=12 N1=1250r/min N2=800r/min N3=1250r/min N4=450r/min

----------

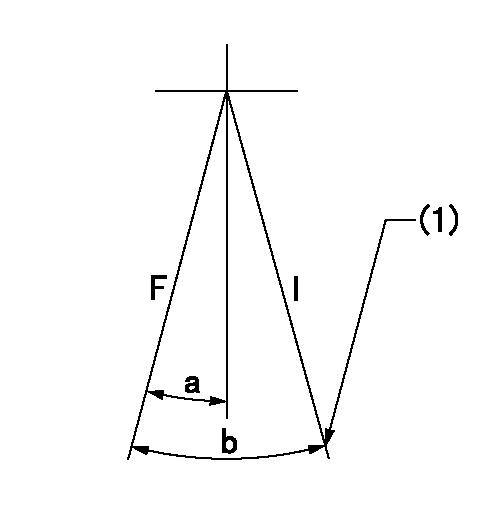

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=16deg+-5deg b=30deg+-5deg

----------

----------

a=16deg+-5deg b=30deg+-5deg

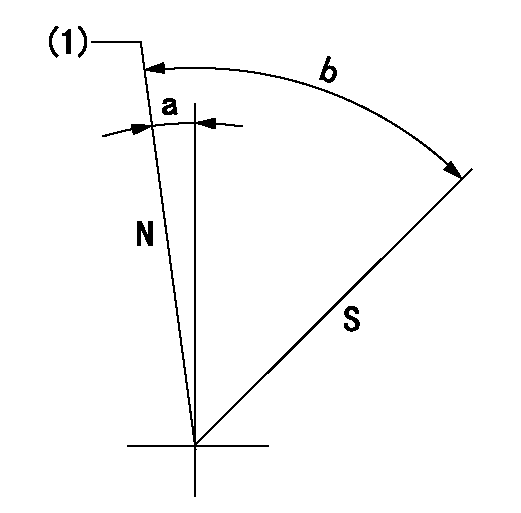

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=7deg+-5deg b=53deg+-5deg

----------

----------

a=7deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Proper operation and maintenance are key factors in obtaining the maximum life and economy of the engine. Following the directions in this manual will lower operating costs.After the engine is started and the cold idle operation is completed, the truck can be operated at low speed and low power. The engine will reach normal operating temperature faster when driven at low speed and low power demand than when idled at no load. Typically the engine should be up to operating temperature by just driving through the yard toward the open road.Engine Operation

* Begin operating the engine at low load. After normal oil pressure is reached and the temperature gauge begins to move, the engine may be operated at full load.* To get the vehicle in motion, use a gear that will result in a smooth, easy start without increasing engine speed above low idle or slipping the clutch. Engage the clutch smoothly. Abrupt or jerky starts put stress on the drive train and waste fuel.* Use progressive shifting to reduce fuel consumption. Progressive shifting is using only the rpm required to make an upshift into the next gear. The amount of rpm required to make an upshift increases as the truck speed increases unless upshifts are made on upgrades. Experience with your truck will show you how much rpm is required to make upshifts under various conditions.* If the truck can be operated in a higher gear after the desired speed is reached, select the highest gear available that will pull the load. By following this recommendation, you will lower your fuel costs, since your engine will be operating at the lowest rpm required to pull the load.Uphill Operation

On upgrades, begin downshifting when the engine rpm starts to approach peak torque (1100-1200 rpm) speed. Fuel economy will be best if you let the engine lug back to around this speed before you downshift. Downshift until a gear is reached in which the engine will pull the load. Allowing the engine to lug below peak torque is permissible if the truck is cresting the top of a hill without downshifting.However, note that extended operation in a lug condition will raise exhaust temperature and cylinder pressure and can lead to reduced engine life.Downhill Operation

Do NOT allow the engine rpm to exceed 2300 rpm, engine damage can result. If equipped with an exhaust brake, do not exceed 2100 rpm.

* When operating the vehicle downhill, do not coast or put the transmission in NEUTRAL.* Select the correct gear that does not allow the engine speed (rpm) to exceed the limits above and use the engine retarder and/or brakes to limit the speed of the truck.* A simple rule to follow is to select the same gear that would be required to go up the grade. However, DO NOT allow the engine to overspeed.For more information on economical operation of this engine, refer to form LEDT5092, Driving Techniques for Maximum Fuel Economy.

* Begin operating the engine at low load. After normal oil pressure is reached and the temperature gauge begins to move, the engine may be operated at full load.* To get the vehicle in motion, use a gear that will result in a smooth, easy start without increasing engine speed above low idle or slipping the clutch. Engage the clutch smoothly. Abrupt or jerky starts put stress on the drive train and waste fuel.* Use progressive shifting to reduce fuel consumption. Progressive shifting is using only the rpm required to make an upshift into the next gear. The amount of rpm required to make an upshift increases as the truck speed increases unless upshifts are made on upgrades. Experience with your truck will show you how much rpm is required to make upshifts under various conditions.* If the truck can be operated in a higher gear after the desired speed is reached, select the highest gear available that will pull the load. By following this recommendation, you will lower your fuel costs, since your engine will be operating at the lowest rpm required to pull the load.Uphill Operation

On upgrades, begin downshifting when the engine rpm starts to approach peak torque (1100-1200 rpm) speed. Fuel economy will be best if you let the engine lug back to around this speed before you downshift. Downshift until a gear is reached in which the engine will pull the load. Allowing the engine to lug below peak torque is permissible if the truck is cresting the top of a hill without downshifting.However, note that extended operation in a lug condition will raise exhaust temperature and cylinder pressure and can lead to reduced engine life.Downhill Operation

Do NOT allow the engine rpm to exceed 2300 rpm, engine damage can result. If equipped with an exhaust brake, do not exceed 2100 rpm.

* When operating the vehicle downhill, do not coast or put the transmission in NEUTRAL.* Select the correct gear that does not allow the engine speed (rpm) to exceed the limits above and use the engine retarder and/or brakes to limit the speed of the truck.* A simple rule to follow is to select the same gear that would be required to go up the grade. However, DO NOT allow the engine to overspeed.For more information on economical operation of this engine, refer to form LEDT5092, Driving Techniques for Maximum Fuel Economy.