Information injection-pump assembly

BOSCH

9 400 611 315

9400611315

ZEXEL

101405-9020

1014059020

Rating:

Service parts 101405-9020 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 315

9400611315

ZEXEL

101405-9020

1014059020

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

48

47

49

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.6+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

13

12

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

60

70

Fixing the lever

*

Rack limit

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

----------

K=9 N1=1200r/min N2=800r/min

----------

----------

K=9 N1=1200r/min N2=800r/min

----------

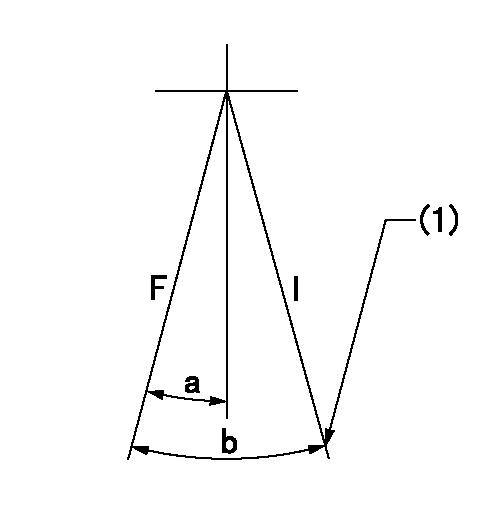

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=7deg+-5deg b=23.5deg+-5deg

----------

----------

a=7deg+-5deg b=23.5deg+-5deg

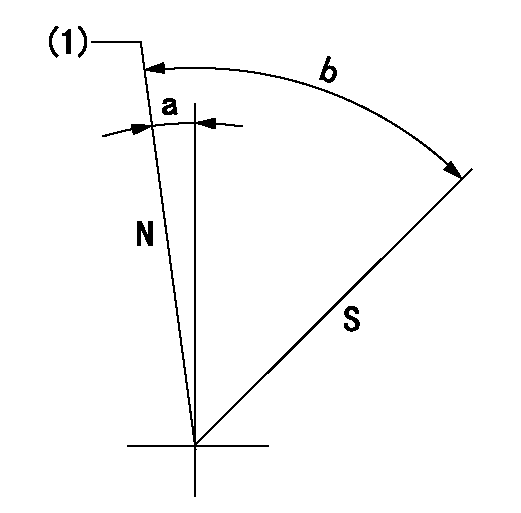

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=7deg+-5deg b=53deg+-5deg

----------

----------

a=7deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Fluid Penetration

Always use a board or cardboard when checking for a leak. Escaping fluid under pressure, even a pin-hole size leak, can penetrate body tissue, causing serious injury, and possible death.If fluid is injected into your skin, it must be treated by a doctor familiar with this type of injury immediately.Asbestos Information

Caution should be used to avoid breathing dust that may be generated when handling components containing asbestos fibers. If this dust is inhaled, it can be hazardous to your health.Components in Caterpillar products that may contain asbestos fibers are brake pads, brake band and lining assemblies, clutch plates and some gaskets.The asbestos used in these components is usually bound in a resin or sealed in some way. Normal handling is not hazardous as long as airborne dust which contains asbestos is not generated.If dust which may contain asbestos is present, there are several common sense guidelines that should be followed.* Never use compressed air for cleaning.* Avoid brushing or grinding of asbestos containing materials.* For clean up, use wet methods or a vacuum equipped with a high efficiency particulate air (HEPA) filter.* Use exhaust ventilation on permanent machining jobs.* Wear an approved respirator if there is no other way to control the dust.* Comply with applicable rules and regulations for the work place (for example in the U.S.A., OSHA requirements as set forth in 29 CFR 1910.1001).* Follow environmental rules and regulations for disposal of asbestos.* Avoid areas where asbestos particles may be in the air.Lines, Tubes And Hoses

Do not bend or strike high pressure lines. Do not install bent or damaged lines, tubes or hoses.Repair any loose or damaged fuel and oil lines, tubes and hoses. Leaks can cause fires.Inspect all lines, tubes and hoses carefully. Do not use your bare hands to check for leaks. Tighten all connections to the recommended torque.* End fittings damaged or leaking.* Outer covering chafed or cut and wire reinforcing exposed.* Outer covering ballooning locally.* Evidence of kinking or crushing of the flexible part of the hose.* Armoring embedded in the outer cover.* End fittings displaced.Burn Prevention

Do not touch any part of an operating engine. Allow the engine to cool before any repairs are performed on the engine.Relieve all pressure in air, oil, fuel or cooling systems before any lines, fittings or related items are disconnected or removed.Coolant

To prevent personal injury, do not step up on engine to remove the filler cap, if applicable. Use an adequate ladder.At operating temperature, the engine coolant is hot and under pressure. The radiator and all lines to heaters or the engine contain hot water. When pressure is relieved rapidly, this hot water can turn into steam.Any contact with hot water or steam can cause severe burns.Check the coolant level only after the engine has been stopped and the filler cap is cool enough to remove with your bare hand.Remove the cooling system filler cap slowly to relieve pressure.Supplemental cooling system additive contains alkali. To prevent personal injury, avoid contact with the skin and

Always use a board or cardboard when checking for a leak. Escaping fluid under pressure, even a pin-hole size leak, can penetrate body tissue, causing serious injury, and possible death.If fluid is injected into your skin, it must be treated by a doctor familiar with this type of injury immediately.Asbestos Information

Caution should be used to avoid breathing dust that may be generated when handling components containing asbestos fibers. If this dust is inhaled, it can be hazardous to your health.Components in Caterpillar products that may contain asbestos fibers are brake pads, brake band and lining assemblies, clutch plates and some gaskets.The asbestos used in these components is usually bound in a resin or sealed in some way. Normal handling is not hazardous as long as airborne dust which contains asbestos is not generated.If dust which may contain asbestos is present, there are several common sense guidelines that should be followed.* Never use compressed air for cleaning.* Avoid brushing or grinding of asbestos containing materials.* For clean up, use wet methods or a vacuum equipped with a high efficiency particulate air (HEPA) filter.* Use exhaust ventilation on permanent machining jobs.* Wear an approved respirator if there is no other way to control the dust.* Comply with applicable rules and regulations for the work place (for example in the U.S.A., OSHA requirements as set forth in 29 CFR 1910.1001).* Follow environmental rules and regulations for disposal of asbestos.* Avoid areas where asbestos particles may be in the air.Lines, Tubes And Hoses

Do not bend or strike high pressure lines. Do not install bent or damaged lines, tubes or hoses.Repair any loose or damaged fuel and oil lines, tubes and hoses. Leaks can cause fires.Inspect all lines, tubes and hoses carefully. Do not use your bare hands to check for leaks. Tighten all connections to the recommended torque.* End fittings damaged or leaking.* Outer covering chafed or cut and wire reinforcing exposed.* Outer covering ballooning locally.* Evidence of kinking or crushing of the flexible part of the hose.* Armoring embedded in the outer cover.* End fittings displaced.Burn Prevention

Do not touch any part of an operating engine. Allow the engine to cool before any repairs are performed on the engine.Relieve all pressure in air, oil, fuel or cooling systems before any lines, fittings or related items are disconnected or removed.Coolant

To prevent personal injury, do not step up on engine to remove the filler cap, if applicable. Use an adequate ladder.At operating temperature, the engine coolant is hot and under pressure. The radiator and all lines to heaters or the engine contain hot water. When pressure is relieved rapidly, this hot water can turn into steam.Any contact with hot water or steam can cause severe burns.Check the coolant level only after the engine has been stopped and the filler cap is cool enough to remove with your bare hand.Remove the cooling system filler cap slowly to relieve pressure.Supplemental cooling system additive contains alkali. To prevent personal injury, avoid contact with the skin and