Information injection-pump assembly

ZEXEL

101405-9001

1014059001

Rating:

Cross reference number

ZEXEL

101405-9001

1014059001

Zexel num

Bosch num

Firm num

Name

101405-9001

INJECTION-PUMP ASSEMBLY

14BD PE4AD PE

14BD PE4AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.4

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

85

84

86

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.9+-0.5

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

14.5

13.5

15.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

11.6++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

130

120

140

Fixing the lever

*

Rack limit

*

Test data Ex:

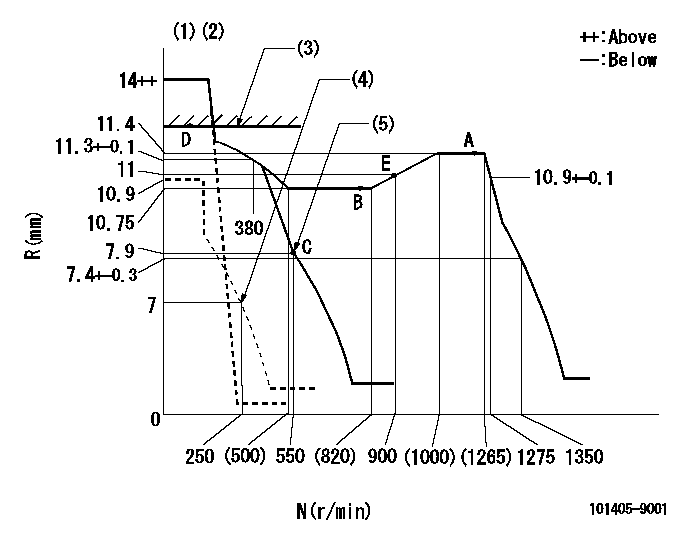

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=9

----------

----------

K=9

----------

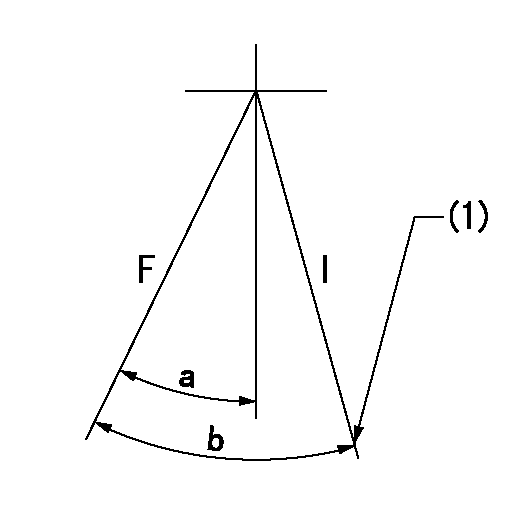

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=16deg+-5deg b=22deg+-5deg

----------

----------

a=16deg+-5deg b=22deg+-5deg

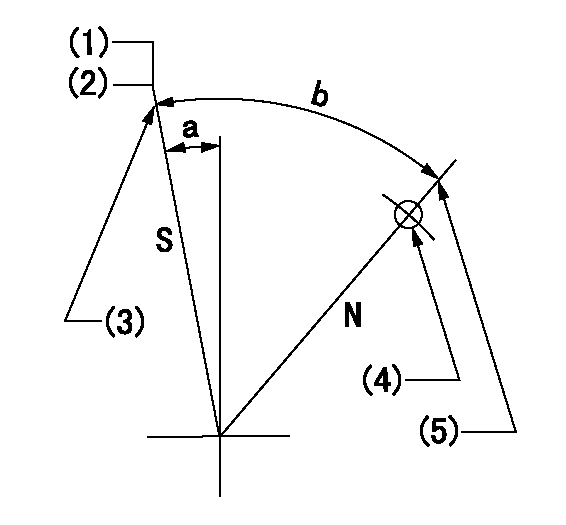

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal stop

(2)Rack position = aa, speed = bb.

(3)Stopper bolt setting

(4)Use the pin above R = cc

(5)Stopper bolt setting

----------

aa=1-0.5mm bb=0r/min cc=30mm

----------

a=13deg+-5deg b=(55deg)

----------

aa=1-0.5mm bb=0r/min cc=30mm

----------

a=13deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

6. No or poor response to throttle

Active Diagnostic Codes: Troubleshoot any active diagnostic codes. ECM: Verify that ECM has completed its start-up self-checks and is out of cold mode. Throttle Position Signal: Check electrical connectors and wiring. Supply voltage to sensor should be between 22 and 27 V DC. Rack Controls: Check electrical connectors and wiring from ECM to rack position sensor and to rack BTM. Measure the signal output to the ECM. Also check for binding of servo or rack.7. Low power/Engine speed (rpm) restricted

Fuel Supply: Check for empty fuel tank, plugged fuel tank connections, obstructed or kinked fuel suction lines, plugged fuel filter, air in fuel system or kinked, leaking or broken fuel lines. Inlet Air System: Check for plugged air filter, aftercooler restrictions, aftercooler leaks, high inlet air temperature. Inspect all gaskets and piping for leaks. Exhaust System: Check for any restrictions. Fuel Injection Nozzle/Pump: If the engine is misfiring or engine speed (rpm) is restricted, run the engine at the speed where the problem is most pronounced. Momentarily loosen the fuel line nut on the injection pump to "cut out" that cylinder. Check each cylinder in this manner. If one is found where loosening makes no difference in irregular operation, the pump and nozzle for that cylinder should be inspected for damage, wear and proper operation. Inspect components for leaks and replace as needed. Fuel Injection Timing: See your authorized dealer. Valve Lash: Adjust valves to specified clearances. Turbocharger: Check for carbon buildup or restricted movement of turbo wheel. Replace if necessary. Auxiliary Attachments: Inspect, align, tighten and check for excessive parasitic loading. Active Diagnostic Codes: Troubleshoot any active diagnostic codes. Factory Parameters: Verify that Full Load Setting and Full Torque Setting are programmed to the values stamped on the engine information plate. Rack Controls: Check electrical connectors and wiring from ECM to rack position sensor and to rack BTM. Measure the signal output to the ECM. Also check for binding of servo or rack. Throttle Position Signal: Check electrical connectors and wiring. Supply voltage to sensor should be between 22 and 27 V DC.8. Intermittent engine shutdowns or power reduction

Fuel Supply: Check for empty fuel tank, plugged fuel tank connections, obstructed or kinked fuel suction lines, plugged fuel filter, air in fuel system or kinked, leaking or broken fuel lines. Shutoff Solenoid: Actuate the control that operates the shutoff solenoid and listen for a "clicking" sound. Power Supply to ECM: Check electrical connectors, wiring and voltage from battery to ECM. Power to ECM should measure 22 to 27 volts. Shutoff Solenoid: Check electrical connectors and wiring. Mechanically override the shutoff solenoid by attaching a lever to the fuel pump. Push lever backward to override the solenoid or forward to shutoff fuel supply. Rack Controls: Check electrical connectors and wiring from ECM to rack position sensor and to rack BTM. Measure the signal output to the ECM. Also check for binding of servo or rack. Engine Speed Signal: (Magnetic Pickup) Check electrical connectors and

Active Diagnostic Codes: Troubleshoot any active diagnostic codes. ECM: Verify that ECM has completed its start-up self-checks and is out of cold mode. Throttle Position Signal: Check electrical connectors and wiring. Supply voltage to sensor should be between 22 and 27 V DC. Rack Controls: Check electrical connectors and wiring from ECM to rack position sensor and to rack BTM. Measure the signal output to the ECM. Also check for binding of servo or rack.7. Low power/Engine speed (rpm) restricted

Fuel Supply: Check for empty fuel tank, plugged fuel tank connections, obstructed or kinked fuel suction lines, plugged fuel filter, air in fuel system or kinked, leaking or broken fuel lines. Inlet Air System: Check for plugged air filter, aftercooler restrictions, aftercooler leaks, high inlet air temperature. Inspect all gaskets and piping for leaks. Exhaust System: Check for any restrictions. Fuel Injection Nozzle/Pump: If the engine is misfiring or engine speed (rpm) is restricted, run the engine at the speed where the problem is most pronounced. Momentarily loosen the fuel line nut on the injection pump to "cut out" that cylinder. Check each cylinder in this manner. If one is found where loosening makes no difference in irregular operation, the pump and nozzle for that cylinder should be inspected for damage, wear and proper operation. Inspect components for leaks and replace as needed. Fuel Injection Timing: See your authorized dealer. Valve Lash: Adjust valves to specified clearances. Turbocharger: Check for carbon buildup or restricted movement of turbo wheel. Replace if necessary. Auxiliary Attachments: Inspect, align, tighten and check for excessive parasitic loading. Active Diagnostic Codes: Troubleshoot any active diagnostic codes. Factory Parameters: Verify that Full Load Setting and Full Torque Setting are programmed to the values stamped on the engine information plate. Rack Controls: Check electrical connectors and wiring from ECM to rack position sensor and to rack BTM. Measure the signal output to the ECM. Also check for binding of servo or rack. Throttle Position Signal: Check electrical connectors and wiring. Supply voltage to sensor should be between 22 and 27 V DC.8. Intermittent engine shutdowns or power reduction

Fuel Supply: Check for empty fuel tank, plugged fuel tank connections, obstructed or kinked fuel suction lines, plugged fuel filter, air in fuel system or kinked, leaking or broken fuel lines. Shutoff Solenoid: Actuate the control that operates the shutoff solenoid and listen for a "clicking" sound. Power Supply to ECM: Check electrical connectors, wiring and voltage from battery to ECM. Power to ECM should measure 22 to 27 volts. Shutoff Solenoid: Check electrical connectors and wiring. Mechanically override the shutoff solenoid by attaching a lever to the fuel pump. Push lever backward to override the solenoid or forward to shutoff fuel supply. Rack Controls: Check electrical connectors and wiring from ECM to rack position sensor and to rack BTM. Measure the signal output to the ECM. Also check for binding of servo or rack. Engine Speed Signal: (Magnetic Pickup) Check electrical connectors and

Have questions with 101405-9001?

Group cross 101405-9001 ZEXEL

Yanmar

101405-9001

INJECTION-PUMP ASSEMBLY