Information injection-pump assembly

BOSCH

9 400 611 882

9400611882

ZEXEL

101405-9000

1014059000

YANMAR

12390151001

12390151001

Rating:

Service parts 101405-9000 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 882

9400611882

ZEXEL

101405-9000

1014059000

YANMAR

12390151001

12390151001

Zexel num

Bosch num

Firm num

Name

9 400 611 882

12390151001 YANMAR

INJECTION-PUMP ASSEMBLY

4TNE106T * K 14BC PE4A,5A, PE

4TNE106T * K 14BC PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

90

89

91

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.9+-0.5

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

14.5

13.5

15.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

130

120

140

Fixing the lever

*

Rack limit

*

Test data Ex:

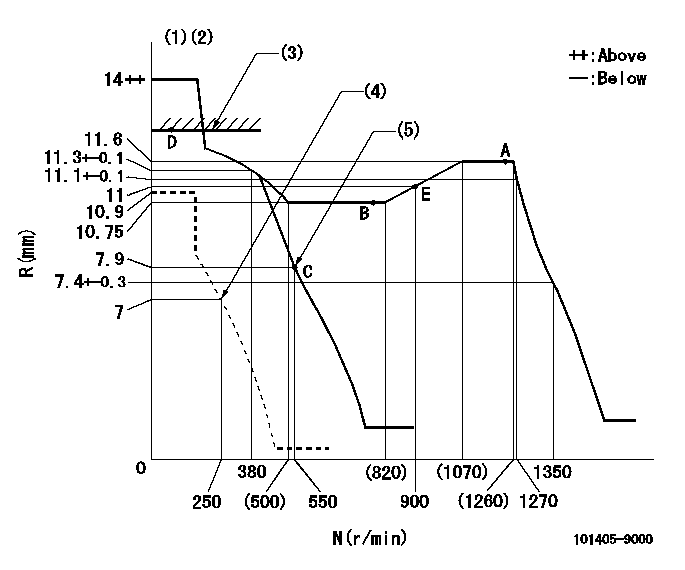

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=9

----------

----------

K=9

----------

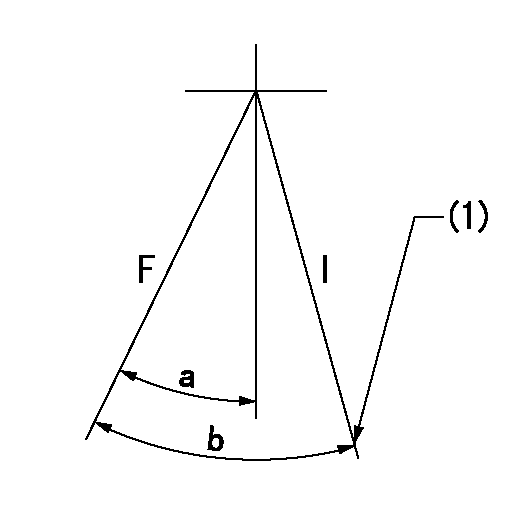

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=16deg+-5deg b=21.5deg+-5deg

----------

----------

a=16deg+-5deg b=21.5deg+-5deg

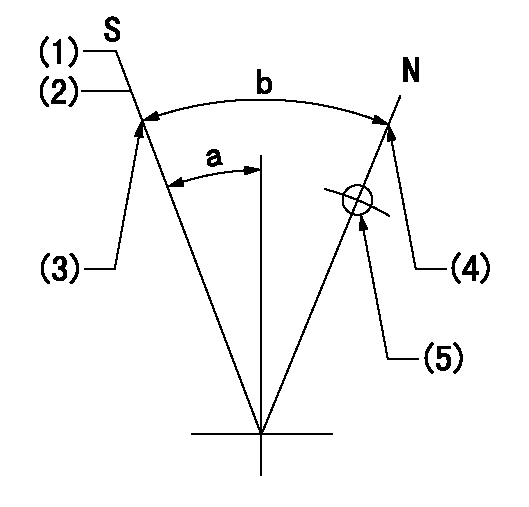

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal stop

(2)Rack position = aa, speed = bb.

(3)Stopper bolt setting

(4)Stopper bolt setting

(5)Use the pin above R = cc

----------

aa=1-0.5mm bb=0r/min cc=30mm

----------

a=13deg+-5deg b=(55deg)

----------

aa=1-0.5mm bb=0r/min cc=30mm

----------

a=13deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

3. Shake the core vigorously to eliminate any trapped debris.4. Wash the core with hot, soapy water. Rinse thoroughly with clean water.5. Dry the core with compressed air. Blow air in reverse direction of normal flow. Use all necessary safety equipment while using compressed air.6. Inspect the system to ensure cleanliness and install the core.Coolant Analysis

Obtain

There are two types of coolant analysis that can be performed. First, the concentration of supplemental coolant additives (conditioner) should be checked regularly for over or under concentration. The intervals recommended for re-charging with supplemental coolant additive should be adequate for many users, but it is a good idea to periodically check the concentration.For checking the concentration of coolant conditioner, Caterpillar offers an 8T5296 test kit.At overhaul time, a further coolant analysis may be desirable. For example, suppose considerable deposits are found in the water jacket areas on the external cooling system, yet supplemental coolant additive concentrations were carefully maintained. Chances are that the coolant water had minerals which deposited on the engine over time. One way to verify the water condition, or to be sure of new water at fill time, is to have a water analysis conducted.Full water analysis can sometimes be obtained locally by contacting your local water utility company or an agricultural agent. Private laboratories are also available. Many Caterpillar dealers and customers send water samples to:L.O.C.C. Corporation

905 Bayshore Drive

Coos Bay, Oregon 97420 U.S.A.

Telephone: (503) 267-4904

NALCO Chemical Co.

Naperville Technical Center

One Nalco Center

Naperville, IL 60566

Attn: Sample Receiving

Ph. (312) 961-9500

To analyze a water sample, most laboratories need approximately 250 ml (1/2 pint) of water. Check the lab you use for details about labeling and shipping.After Failure Overhaul

If you experience a major engine failure which requires removal of the engine, there are also many After Failure Overhaul options available. An overhaul should be performed if your block or crankshaft needs to be repaired.If the block and/or crankshaft is repairable, then the cost of an overhaul should be between 40 and 50 percent of the cost of a new engine (with like exchange core).This lower cost can be attributed to Caterpillar "designed-in" features that include:* Regrindable crankshaft* Undersize bearings, if needed* Cat dealer and Caterpillar Remanufactured exchange components Dealer Exchange Components - This cost cutting service permits you to exchange worn engine components for quality Caterpillar dealer rebuilt components on an over-the-counter basis. When you need them, these parts are ready for a substantial savings in both time and money. Caterpillar Remanufactured Components - Manufacturing techniques and processes are used to restore your components to "like-new" performance capabilities and are exchanged for your existing parts. The processes used result in an end product that conforms to Caterpillar's original functional specifications.The following is a list of (R) Remanufactured components that can be found in the Parts Book and currently being offered by Caterpillar* in many countries:* Short block* Cylinder pack1* Cylinder head - bare casting* Cylinder head - assembled* Crankshaft - undersized*** Crankshaft - upgrade to new* Complete turbocharger* Turbocharger Piece Parts* Turbocharger Cartridges*

Obtain

There are two types of coolant analysis that can be performed. First, the concentration of supplemental coolant additives (conditioner) should be checked regularly for over or under concentration. The intervals recommended for re-charging with supplemental coolant additive should be adequate for many users, but it is a good idea to periodically check the concentration.For checking the concentration of coolant conditioner, Caterpillar offers an 8T5296 test kit.At overhaul time, a further coolant analysis may be desirable. For example, suppose considerable deposits are found in the water jacket areas on the external cooling system, yet supplemental coolant additive concentrations were carefully maintained. Chances are that the coolant water had minerals which deposited on the engine over time. One way to verify the water condition, or to be sure of new water at fill time, is to have a water analysis conducted.Full water analysis can sometimes be obtained locally by contacting your local water utility company or an agricultural agent. Private laboratories are also available. Many Caterpillar dealers and customers send water samples to:L.O.C.C. Corporation

905 Bayshore Drive

Coos Bay, Oregon 97420 U.S.A.

Telephone: (503) 267-4904

NALCO Chemical Co.

Naperville Technical Center

One Nalco Center

Naperville, IL 60566

Attn: Sample Receiving

Ph. (312) 961-9500

To analyze a water sample, most laboratories need approximately 250 ml (1/2 pint) of water. Check the lab you use for details about labeling and shipping.After Failure Overhaul

If you experience a major engine failure which requires removal of the engine, there are also many After Failure Overhaul options available. An overhaul should be performed if your block or crankshaft needs to be repaired.If the block and/or crankshaft is repairable, then the cost of an overhaul should be between 40 and 50 percent of the cost of a new engine (with like exchange core).This lower cost can be attributed to Caterpillar "designed-in" features that include:* Regrindable crankshaft* Undersize bearings, if needed* Cat dealer and Caterpillar Remanufactured exchange components Dealer Exchange Components - This cost cutting service permits you to exchange worn engine components for quality Caterpillar dealer rebuilt components on an over-the-counter basis. When you need them, these parts are ready for a substantial savings in both time and money. Caterpillar Remanufactured Components - Manufacturing techniques and processes are used to restore your components to "like-new" performance capabilities and are exchanged for your existing parts. The processes used result in an end product that conforms to Caterpillar's original functional specifications.The following is a list of (R) Remanufactured components that can be found in the Parts Book and currently being offered by Caterpillar* in many countries:* Short block* Cylinder pack1* Cylinder head - bare casting* Cylinder head - assembled* Crankshaft - undersized*** Crankshaft - upgrade to new* Complete turbocharger* Turbocharger Piece Parts* Turbocharger Cartridges*