Information injection-pump assembly

BOSCH

9 400 612 937

9400612937

ZEXEL

101402-9971

1014029971

YANMAR

12390051000

12390051000

Rating:

Service parts 101402-9971 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 612 937

9400612937

ZEXEL

101402-9971

1014029971

YANMAR

12390051000

12390051000

Zexel num

Bosch num

Firm num

Name

101402-9971

9 400 612 937

12390051000 YANMAR

INJECTION-PUMP ASSEMBLY

4TNE106 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4TNE106 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.7

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

73.5

72.5

74.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.6+-0.5

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

13

12

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

11.6++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

100

95

105

Fixing the lever

*

Rack limit

*

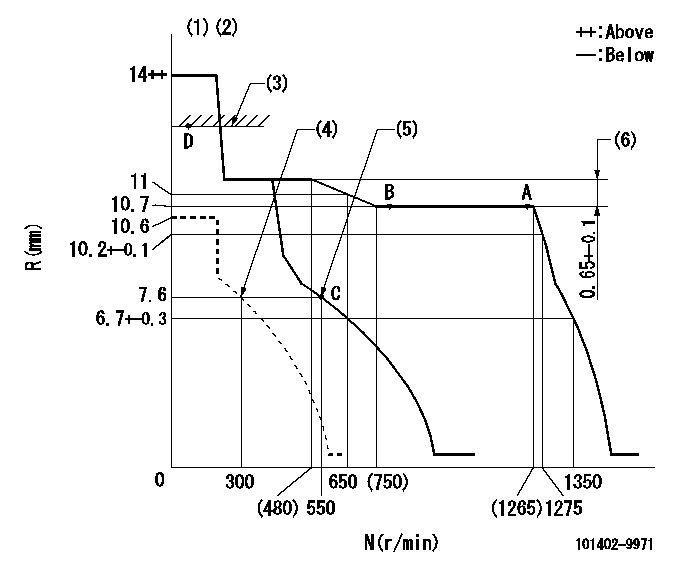

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

----------

K=12 N1=1250r/min N2=400r/min

----------

----------

K=12 N1=1250r/min N2=400r/min

----------

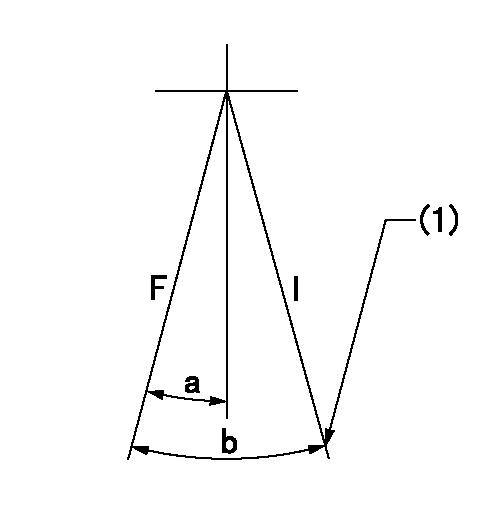

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=17deg+-5deg b=26deg+-5deg

----------

----------

a=17deg+-5deg b=26deg+-5deg

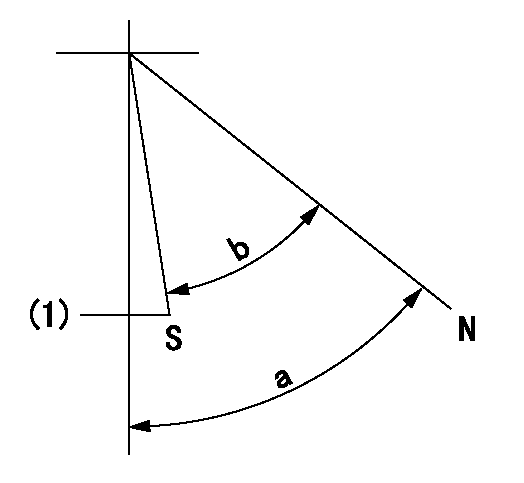

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal stop

----------

----------

a=58deg+-5deg b=53deg+-5deg

----------

----------

a=58deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Tachometer Drive

Use a short fiber grease, No. 2 Grade for most temperatures, or No. 0 or No. 1 for extremely low temperatures. Wipe surrounding area with a clean rag before removing plug. Remove plug. Install grease fitting. Apply two strokes of lubricant through the fitting. Remove grease fitting. Replace plug.Governor Control Cross Shaft Bearings (1673)

Engines Before 69D3625)

Use a short fiber grease No. 2 Grade for most temperatures, or No. 0 or No. 1 for extremely low temperatures. Apply 1 stroke of lubricant through fitting at each end of shaft.Valve Adjustment

1673C

Make valve adjustment with engine stopped and cold. Remove the flywheel timing cover and rotate flywheel in direction of engine rotation until "TC 1-6 cyl" mark aligns with timing pointer. Remove valve cover and observe position of valves to determine if No. 1 or No. 6 piston is on compression stroke. Both the inlet and exhaust valves will be closed on compression stroke.1. With No. 1 piston at TDC on compression, check lash on exhaust valves for cylinders 1, 3 and 5, and inlet valves for cylinders 1, 2 and 4.2. To adjust, loosen valve adjusting locknut and turn adjusting screw to allow feeler gauge to pass between top of valve stem and the valve rocker arm.3. Set lash at .015" (0.38 mm) for inlet and .025" (0.63 mm) for exhaust valves.4. Tighten adjusting screw locknut and check lash clearance.5. Turn flywheel 360° in direction of engine rotation. Align flywheel timing mark with pointer. No. 6 cylinder will be at TDC compression stroke (valves closed).6. Check lash on exhaust valves for cylinders 2, 4 and 6, and inlet valves for cylinders 3, 5 and 6. Adjust valves if necessary.1674

Make valve lash adjustment with engine stopped. TDC of the No. 1 piston on the compression stroke is the reference point. The No. 1 piston will be at TDC when the No. 1 and No. 6 flywheel timing mark aligns with the timing pointer. Compression stroke is when all the No. 1 piston valves are closed.1. With No. 1 piston at TDC compression stroke, adjust lash on 1, 3 and 5 exhaust and 1, 2 and 4 inlet valves.2. Turn adjusting screw counterclockwise 2 clicks or more to provide clearance between rocker assembly and valve.3. Turn adjusting screw clockwise to obtain zero lash. There should be no free rocker movement or adjusting screw button lateral movement. The adjusting screw button can still be rotated by finger pressure even when it is in contact with valve stem and clearance is zero. Turning the adjusting screw clockwise beyond this point will force the valve off its seat, and final lash setting will be incorrect.4. To adjust, turn adjustment screw counterclockwise 10 clicks (.020") (0.51 mm) for the exhaust valves and 4 clicks (.008") (0.20 mm) for the inlet valves. (One click is equal to .002") (0.05 mm).5. Turn crankshaft 360° clockwise, (direction of normal rotation) viewing from front. Align flywheel timing mark with timing pointer. a) Adjust 2, 4 and 6 exhaust

Use a short fiber grease, No. 2 Grade for most temperatures, or No. 0 or No. 1 for extremely low temperatures. Wipe surrounding area with a clean rag before removing plug. Remove plug. Install grease fitting. Apply two strokes of lubricant through the fitting. Remove grease fitting. Replace plug.Governor Control Cross Shaft Bearings (1673)

Engines Before 69D3625)

Use a short fiber grease No. 2 Grade for most temperatures, or No. 0 or No. 1 for extremely low temperatures. Apply 1 stroke of lubricant through fitting at each end of shaft.Valve Adjustment

1673C

Make valve adjustment with engine stopped and cold. Remove the flywheel timing cover and rotate flywheel in direction of engine rotation until "TC 1-6 cyl" mark aligns with timing pointer. Remove valve cover and observe position of valves to determine if No. 1 or No. 6 piston is on compression stroke. Both the inlet and exhaust valves will be closed on compression stroke.1. With No. 1 piston at TDC on compression, check lash on exhaust valves for cylinders 1, 3 and 5, and inlet valves for cylinders 1, 2 and 4.2. To adjust, loosen valve adjusting locknut and turn adjusting screw to allow feeler gauge to pass between top of valve stem and the valve rocker arm.3. Set lash at .015" (0.38 mm) for inlet and .025" (0.63 mm) for exhaust valves.4. Tighten adjusting screw locknut and check lash clearance.5. Turn flywheel 360° in direction of engine rotation. Align flywheel timing mark with pointer. No. 6 cylinder will be at TDC compression stroke (valves closed).6. Check lash on exhaust valves for cylinders 2, 4 and 6, and inlet valves for cylinders 3, 5 and 6. Adjust valves if necessary.1674

Make valve lash adjustment with engine stopped. TDC of the No. 1 piston on the compression stroke is the reference point. The No. 1 piston will be at TDC when the No. 1 and No. 6 flywheel timing mark aligns with the timing pointer. Compression stroke is when all the No. 1 piston valves are closed.1. With No. 1 piston at TDC compression stroke, adjust lash on 1, 3 and 5 exhaust and 1, 2 and 4 inlet valves.2. Turn adjusting screw counterclockwise 2 clicks or more to provide clearance between rocker assembly and valve.3. Turn adjusting screw clockwise to obtain zero lash. There should be no free rocker movement or adjusting screw button lateral movement. The adjusting screw button can still be rotated by finger pressure even when it is in contact with valve stem and clearance is zero. Turning the adjusting screw clockwise beyond this point will force the valve off its seat, and final lash setting will be incorrect.4. To adjust, turn adjustment screw counterclockwise 10 clicks (.020") (0.51 mm) for the exhaust valves and 4 clicks (.008") (0.20 mm) for the inlet valves. (One click is equal to .002") (0.05 mm).5. Turn crankshaft 360° clockwise, (direction of normal rotation) viewing from front. Align flywheel timing mark with timing pointer. a) Adjust 2, 4 and 6 exhaust

Have questions with 101402-9971?

Group cross 101402-9971 ZEXEL

Daewoo

Daewoo

Yanmar

Mitsubishi-Heav

Yanmar

Yanmar

Yanmar

Yanmar

101402-9971

9 400 612 937

12390051000

INJECTION-PUMP ASSEMBLY

4TNE106

4TNE106