Information injection-pump assembly

BOSCH

9 400 611 818

9400611818

ZEXEL

101402-9970

1014029970

Rating:

Service parts 101402-9970 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 818

9400611818

ZEXEL

101402-9970

1014029970

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.7

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

73.5

72.5

74.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.6+-0.5

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

13

12

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

100

95

105

Fixing the lever

*

Rack limit

*

Test data Ex:

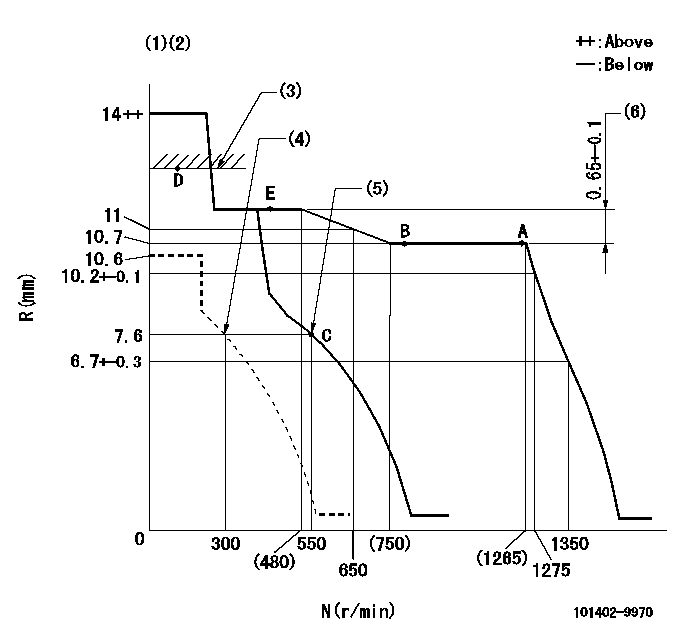

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

----------

K=12 N1=1250r/min N2=400r/min

----------

----------

K=12 N1=1250r/min N2=400r/min

----------

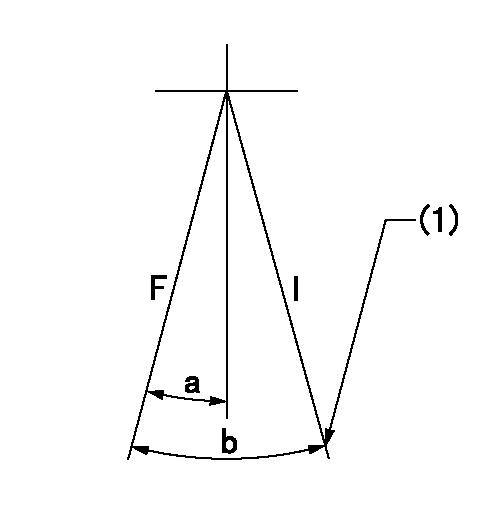

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=17deg+-5deg b=26deg+-5deg

----------

----------

a=17deg+-5deg b=26deg+-5deg

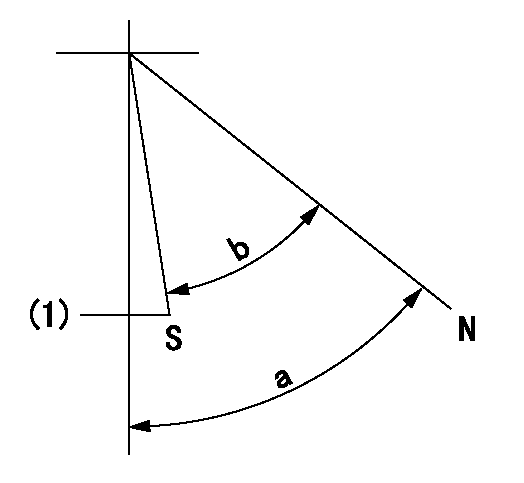

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At delivery

----------

----------

a=58deg+-5deg b=53deg+-5deg

----------

----------

a=58deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Proper operation and maintenance are key factors in determining the useful life and economy of a truck engine. Follow the directions in this guide for trouble-free, economical truck engine operation. After the engine starts, reduce engine RPM to low idle with no load.(1674 and 1693: Before normal oil pressure is reached the governor control linkage travel is limited to below half engine speed by an oil pressure actuated stop inside the governor.) Do not attempt to force the governor control linkage past the stop. When normal oil pressure is reached, operate the engine at low load for 5 minutes before applying full load.Select the lowest gear for a smooth, easy start without slipping the clutch. Rapid engine acceleration causes heavy exhaust smoke and high fuel consumption with no increase in vehicle performance. For best performance, do not skip gears when loaded.Caterpillar engines have good lugging characteristics; however, avoid operating in a lug condition for extended periods of time as it causes exhaust temperatures to rise and results in high fuel consumption. A lug condition exists when an increase in engine speed cannot be achieved with an increase in accelerator pedal position, or when engine speed decreases with the accelerator pedal in its maximum position. A lug condition can exist at any engine speed below full load speed.Continue to upshift until cruising speed is reached. Cruising speed should be between three-fourths and full governed RPM. (The governor will maintain a constant speed without accelerator pedal correction.)On upgrade, begin downshifting if engine starts to labor. Downshift until a gear is reached in which the engine will pull the load without lugging. For best performance, downshift before engine RPM falls below peak torque RPM (see page 2).On downgrade, do not coast or put transmission in neutral. Select the correct gear to keep engine speed below idle and retard the vehicle. A simple rule to follow is to select the same gear that would be used to go up the grade. Do not allow engine speed to exceed high idle.Before stopping the engine, operate at low load for 5 minutes, then at low idle for 30 seconds. (This procedure allows hot areas in the engine to cool gradually, extending the engine life.) To stop the engine, use one of the methods listed. TO STOP THE ENGINE, DO ONE OF THE FOLLOWING, DEPENDING ON TRUCK ARRANGEMENT1. Turn the key to the spring-loaded position and hold until engine stops, then release key, or2. Pull out the manual shutoff control, or3. Push in and hold stop button until engine stops, then release button, or4. Pull up on the accelerator.