Information injection-pump assembly

BOSCH

9 400 611 230

9400611230

ZEXEL

101402-9950

1014029950

Rating:

Service parts 101402-9950 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 230

9400611230

ZEXEL

101402-9950

1014029950

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.7

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

71

70

72

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.6+-0.5

Pump speed

r/min

940

940

940

Average injection quantity

mm3/st.

9

8

10

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

70

80

Fixing the lever

*

Rack limit

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

----------

K=12

----------

----------

K=12

----------

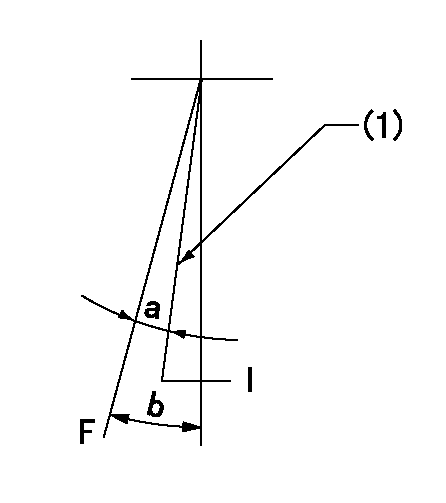

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(1deg)+-5deg b=(1deg)+-5deg

----------

----------

a=(1deg)+-5deg b=(1deg)+-5deg

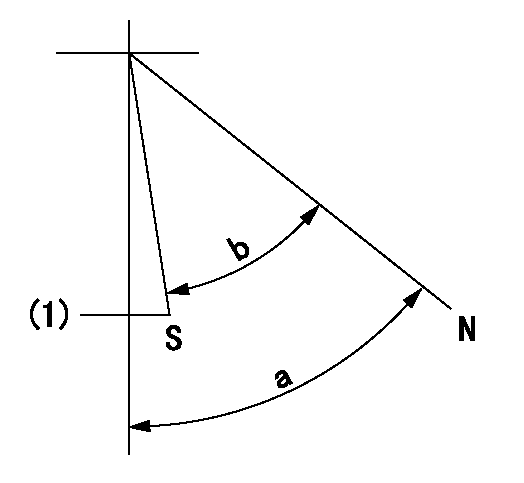

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal stop

----------

----------

a=58deg+-5deg b=53deg+-5deg

----------

----------

a=58deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

INSTALLING ENGINE TURNING TOOLBoth the inlet and exhaust valves will be closed on compression stroke. First check the bridge adjustment and then the valve lash adjustment. Bridge Adjustment

Check the bridge adjustment screw and locknut for tightness. If the adjusting screw and locknut are tight, proceed with the valve lash adjustment. If the bridge adjusting screw can be turned with a screwdriver without holding the locknut, the bridge requires adjustment. The bridge adjustment must be made before the valve lash is checked for proper clearance.Make bridge adjustment as follows:1. Back off adjusting screw several turns (counterclockwise) making sure it is not in contact with the valve stem.2. Firmly press straight down on the rocker arm above point of contact with bridge.

ADJUSTING BRIDGE3. Turn the adjusting screw clockwise until contact is made with the valve stem, then turn the adjusting screw an additional 30° or 1/12 turn (1/2 the distance between the two points on the locknut).4. Hold the adjusting screw in this position and tighten the locknut to 20 lb. ft. (27.2 N m).

TIGHTENING ADJUSTING SCREW LOCKNUTValve Lash Adjustment

To prevent possible injury, do not use the starter motor to turn the flywheel.Hot engine components can cause burns. Allow additional time for the engine to cool before measuring valve clearance.

Measure the valve lash with the engine stopped. To obtain an accurate measurement, allow at least 20 minutes for the valves to cool to cylinder head and block temperature.

If the valve clearance is within 0.08 mm (.003 in) of the nominal clearance given, adjustment is not required. If the clearance is not within these limits, set the clearance as given in the chart. After checking the bridge adjustment, make the valve lash adjustment.1. With No. 1 piston at TDC on compression, check valve lash between the bridge and rocker arm. See chart for cylinder and valve adjusting sequence.2. To adjust, loosen valve adjusting locknut and turn adjusting screw to allow feeler gauge to pass between top of bridge and the valve rocker arm. Set the inlet valve lash at .015" (0.38 mm) and exhaust valve lash at .030" (0.76 mm). 3. After proper adjustment, tighten the adjusting screw locknut to 22 lb. ft. (29.9 N m) and recheck lash clearance. 4. Turn flywheel 360° in direction of engine rotation. Align flywheel timing bolt with the timing hole in the flywheel. 3408-No. 6 Cylinder will be at TDC on compression stroke (all valves closed)3412-No. 11 Cylinder will be at TDC on compression stroke (all valves closed).5. Check lash and adjust as necessary on all remaining valves, see valve adjusting sequence chart.6. Tighten locknut and recheck lash clearance.7. Remove engine turning tool and install timing access cover, timing bolt and plug.Check Valve Rotation: After checking valve lash and before the valve covers are installed, check the valves for rotation.1. Mark a line on each valve retainer.2. Start the engine and run at low idle.3. Watch the line mark on each valve retainer. Each valve retainer should turn slightly each time the valve