Information injection-pump assembly

BOSCH

9 400 611 314

9400611314

ZEXEL

101402-9840

1014029840

MITSUBISHI-HEAV

3426113030

3426113030

Rating:

Service parts 101402-9840 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 314

9400611314

ZEXEL

101402-9840

1014029840

MITSUBISHI-HEAV

3426113030

3426113030

Zexel num

Bosch num

Firm num

Name

101402-9840

9 400 611 314

3426113030 MITSUBISHI-HEAV

INJECTION-PUMP ASSEMBLY

S4K K 14BC INJECTION PUMP ASSY PE4A,5A, PE

S4K K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.1

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

76.5

75.5

77.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

5.1+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

12

10.7

13.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

65

70

Fixing the lever

*

Rack limit

*

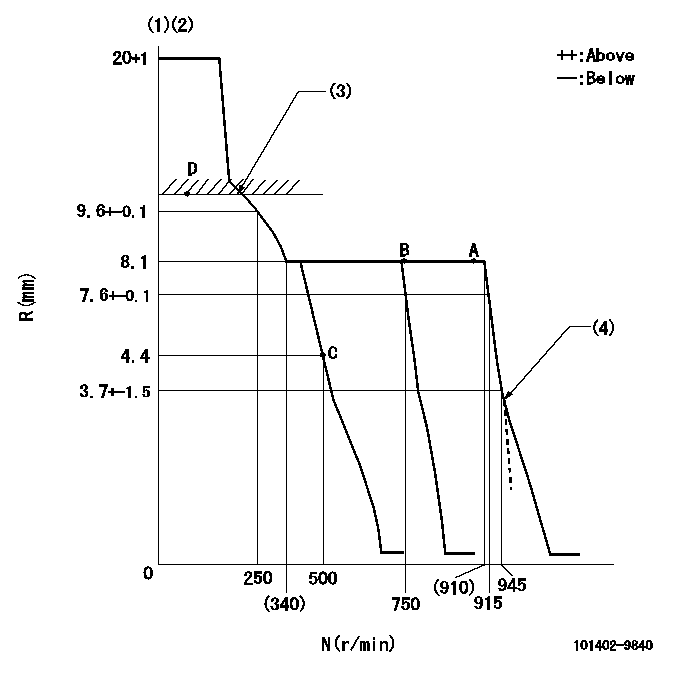

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Idle sub spring setting: L1.

----------

K=5 L1=3.4+-0.1mm

----------

----------

K=5 L1=3.4+-0.1mm

----------

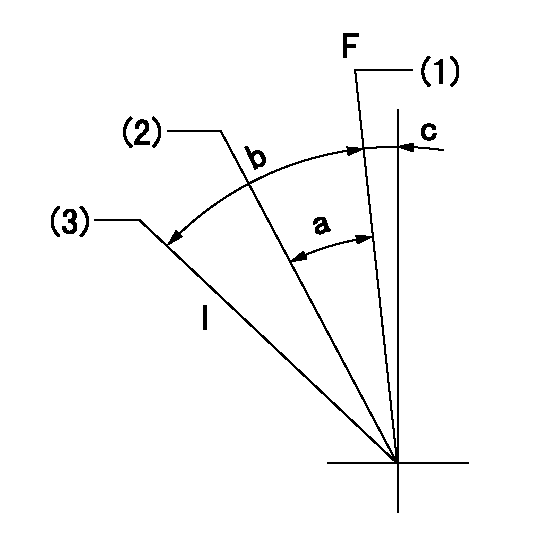

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa

(2)Set the pump speed at bb.

(3)Stopper bolt setting

----------

aa=915r/min bb=750r/min

----------

a=(5deg)+-5deg b=(14deg)+-5deg c=(4deg)+-5deg

----------

aa=915r/min bb=750r/min

----------

a=(5deg)+-5deg b=(14deg)+-5deg c=(4deg)+-5deg

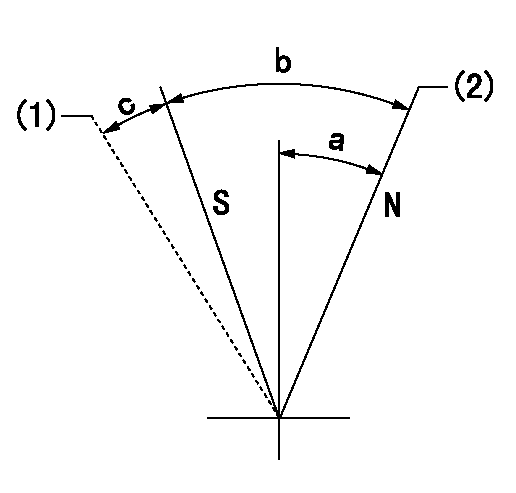

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Hold the boss against the stop side

(2)Normal

----------

----------

a=26.5deg+-5deg b=53deg+-5deg c=(11deg)

----------

----------

a=26.5deg+-5deg b=53deg+-5deg c=(11deg)

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

1. Install tooling (A) on the BrakeSaver housing and rotor. Tooling (A) holds the BrakeSaver housing and rotor assembly together at installation. This prevents damage to the rotor rings and seals.2. Install a 3/8 in. - 16 NC forged eyebolt in the top of the BrakeSaver housing, and fasten a hoist to it.3. Install two 5/8 in. - 18 guide bolts (9) in the crankshaft as shown. Make sure dowel (8) is in alignment with the dowel hole in the rotor assembly, and put BrakeSaver housing (7) in position in the flywheel housing.4. Install the three bolts that hold the BrakeSaver housing to the flywheel housing. Remove tooling (A) and guide pins (9). 5. Connect the oil line to fitting (5).6. Inspect the O-ring seals for damage, and make replacements if needed. Install O-ring seals (10) and (11). Put clean engine oil on the O-ring seals.7. Install manifold (12) into the BrakeSaver control valve, and install the four bolts that hold the manifold to the BrakeSaver housing. 8. Connect BrakeSaver lubrication oil line (1) to the fitting in the BrakeSaver housing.End By:a. install flywheel (BrakeSaver)Disassemble BrakeSaver

Start By:a. remove BrakeSaver1. Remove tooling (A) from the BrakeSaver housing and rotor. Tooling (A) prevents damage to the rotor seals and rings during removal of the BrakeSaver housing. 2. Remove bolts (1) from gear plate (2). Remove the plate. 3. Put alignment marks on stator (3) and housing (4) for assembly purposes. Remove bolts (5) and the stator. 4. Turn the stator over, and remove spiral ring (6). 5. Turn the stator over again. Remove sleeve assembly (9). Remove O-ring seal (7) and lip-type seal (8) from the sleeve. 6. Remove O-ring seal (11) and the six smaller O-ring seals from the oil holes on the housing.7. Remove rotor assembly (12).8. Remove seal ring (10) from both sides of the rotor. 9. Remove carrier (13) and wear sleeve (14) with tooling (B) from both sides of the rotor. 10. Remove spiral ring (15). Turn the housing over, and remove sleeve assembly (17). Remove the lip-type seal and O-ring seal (16) from the sleeve.Assemble BrakeSaver

1. Inspect the O-ring seals for damage, and make replacements if needed. Put clean engine oil on the O-ring seals. 2. Install O-ring seal (16) on sleeve (17).3. Install the sleeve in the BrakeSaver housing. Make

Start By:a. remove BrakeSaver1. Remove tooling (A) from the BrakeSaver housing and rotor. Tooling (A) prevents damage to the rotor seals and rings during removal of the BrakeSaver housing. 2. Remove bolts (1) from gear plate (2). Remove the plate. 3. Put alignment marks on stator (3) and housing (4) for assembly purposes. Remove bolts (5) and the stator. 4. Turn the stator over, and remove spiral ring (6). 5. Turn the stator over again. Remove sleeve assembly (9). Remove O-ring seal (7) and lip-type seal (8) from the sleeve. 6. Remove O-ring seal (11) and the six smaller O-ring seals from the oil holes on the housing.7. Remove rotor assembly (12).8. Remove seal ring (10) from both sides of the rotor. 9. Remove carrier (13) and wear sleeve (14) with tooling (B) from both sides of the rotor. 10. Remove spiral ring (15). Turn the housing over, and remove sleeve assembly (17). Remove the lip-type seal and O-ring seal (16) from the sleeve.Assemble BrakeSaver

1. Inspect the O-ring seals for damage, and make replacements if needed. Put clean engine oil on the O-ring seals. 2. Install O-ring seal (16) on sleeve (17).3. Install the sleeve in the BrakeSaver housing. Make

Have questions with 101402-9840?

Group cross 101402-9840 ZEXEL

Yanmar

Mitsubishi-Heav

101402-9840

9 400 611 314

3426113030

INJECTION-PUMP ASSEMBLY

S4K

S4K