Information injection-pump assembly

ZEXEL

101402-9760

1014029760

Rating:

Cross reference number

ZEXEL

101402-9760

1014029760

Zexel num

Bosch num

Firm num

Name

101402-9760

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

87

86

88

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.1+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

8

6

10

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85

85

95

Fixing the lever

*

Rack limit

*

Test data Ex:

Governor adjustment

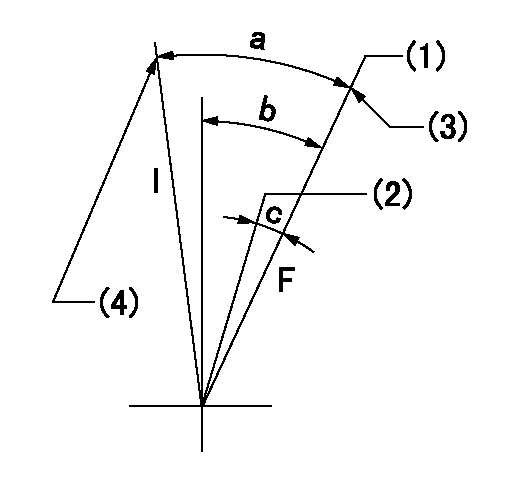

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=14

----------

----------

K=14

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)When pump speed set at bb

(3)Stopper bolt setting

(4)Stopper bolt setting

----------

aa=1825r/min bb=1525r/min

----------

a=32deg+-5deg b=27deg+-5deg c=9deg+-5deg

----------

aa=1825r/min bb=1525r/min

----------

a=32deg+-5deg b=27deg+-5deg c=9deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=12deg+-5deg b=53deg+-5deg

----------

----------

a=12deg+-5deg b=53deg+-5deg

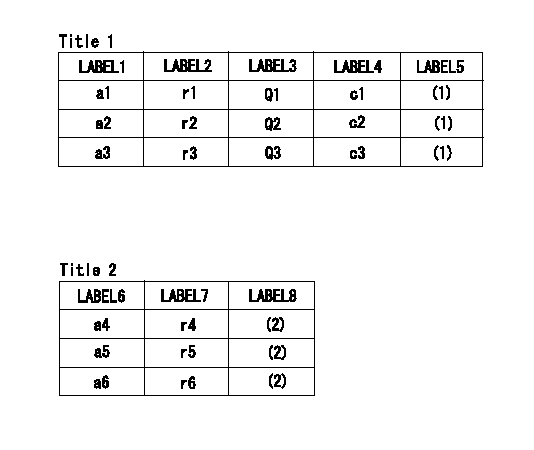

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)-

----------

----------

a1=A a2=B a3=C r1=1500r/min r2=1500r/min r3=1500r/min Q1=- Q2=87+-1mm3/st Q3=- c1=- c2=+-3.5% c3=- a4=36 a5=30 a6=- r4=1800r/min r5=1500r/min r6=-

----------

----------

a1=A a2=B a3=C r1=1500r/min r2=1500r/min r3=1500r/min Q1=- Q2=87+-1mm3/st Q3=- c1=- c2=+-3.5% c3=- a4=36 a5=30 a6=- r4=1800r/min r5=1500r/min r6=-

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'ZZ' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(100deg)

----------

aa=16deg

----------

a=(100deg)

Information:

2. Loosen the clamps on breather tube (1), and pull it back for clearance. 3. Remove bolt (2) from the cover on the side of the cylinder block. 4. Remove the three bolts that hold cover (3) to the water pump. Remove cover (3) from the water pump. 5. Remove two bolts (4), and remove bonnet (5). 6. Remove six bolts (6) that hold the water pump to the timing gear cover. Remove the water pump.7. Check the O-ring seals and gaskets, and make replacements if needed.For the installation of the water pump reverse the removal procedures.8. See Maintenance Manual for coolant refill.End By:a. remove alternator and mounting groupb. remove water temperature regulator and manifoldDisassemble & Assemble Water Pump

Start By:a. remove water pump The water pump seal can be replaced without removing the water pump from the engine.An intermittent leakage of a small amount of coolant from the hole in the water pump housing is not an indication of a water pump seal failure. This is required to provide lubrication for the seal. Replace the water pump seal only if a large amount of leakage or a constant flow of coolant is observed draining from the water pump housing. 1. Remove O-ring seal (3) from adapter (4). Remove the adapter from housing (7). Remove the O-ring seal from the outside of the adapter.2. Remove bolt (1) and washer (2). Use tooling (A) to remove impeller (6) from shaft (13).3. Remove spring and seal (5) from the shaft.4. Remove four bolts (16) from retainer (12) that hold the shaft assembly to the pump housing. Remove O-ring seal (18) from housing (7).5. Remove gear and shaft assembly (17) from the housing. Remove bolt (15), retainer (14), and retainer (12) from the shaft assembly.6. Use a press to remove shaft (13) from the gear. Remove bearing (9), spacer (10), and bearing (11) from the shaft.7. Remove lip-type seal (8) from the housing.8. Turn the housing over, and remove ceramic ring (20) and seal (19) from the housing. The following steps are for the assembly of the water pump.9. Use 6V1541 Quick Cure Primer and clean shaft (13) and the seal counter bore in the pump housing.10. Install bearing (9), spacer (10), and bearing (11) on shaft (13).11. Put retainer (12) and gear (17) on the shaft assembly. Install retainer (14) and bolt (15) on the shaft.12. Use tooling (B) to install lip-type seal (8) in housing (7). Install seal with the lip toward the inside of the housing. Put a small amount of clean engine oil on the lip of the seal.13. Install a new O-ring seal (18) on the housing.14. Put gear and shaft assembly (17) in position in the housing. Install bolts (16) that hold retainer (12) to the housing.

Clean water only is permitted for use as a lubricant for assistance at installation. Do not damage or put hands on the wear surface of the carbon ring or the ceramic ring. Install the ceramic ring with the smoothest face

Start By:a. remove water pump The water pump seal can be replaced without removing the water pump from the engine.An intermittent leakage of a small amount of coolant from the hole in the water pump housing is not an indication of a water pump seal failure. This is required to provide lubrication for the seal. Replace the water pump seal only if a large amount of leakage or a constant flow of coolant is observed draining from the water pump housing. 1. Remove O-ring seal (3) from adapter (4). Remove the adapter from housing (7). Remove the O-ring seal from the outside of the adapter.2. Remove bolt (1) and washer (2). Use tooling (A) to remove impeller (6) from shaft (13).3. Remove spring and seal (5) from the shaft.4. Remove four bolts (16) from retainer (12) that hold the shaft assembly to the pump housing. Remove O-ring seal (18) from housing (7).5. Remove gear and shaft assembly (17) from the housing. Remove bolt (15), retainer (14), and retainer (12) from the shaft assembly.6. Use a press to remove shaft (13) from the gear. Remove bearing (9), spacer (10), and bearing (11) from the shaft.7. Remove lip-type seal (8) from the housing.8. Turn the housing over, and remove ceramic ring (20) and seal (19) from the housing. The following steps are for the assembly of the water pump.9. Use 6V1541 Quick Cure Primer and clean shaft (13) and the seal counter bore in the pump housing.10. Install bearing (9), spacer (10), and bearing (11) on shaft (13).11. Put retainer (12) and gear (17) on the shaft assembly. Install retainer (14) and bolt (15) on the shaft.12. Use tooling (B) to install lip-type seal (8) in housing (7). Install seal with the lip toward the inside of the housing. Put a small amount of clean engine oil on the lip of the seal.13. Install a new O-ring seal (18) on the housing.14. Put gear and shaft assembly (17) in position in the housing. Install bolts (16) that hold retainer (12) to the housing.

Clean water only is permitted for use as a lubricant for assistance at installation. Do not damage or put hands on the wear surface of the carbon ring or the ceramic ring. Install the ceramic ring with the smoothest face

Have questions with 101402-9760?

Group cross 101402-9760 ZEXEL

Mitsubishi-Heav

Nissan-Diesel

Nissan-Diesel

Yanmar

Yanmar

101402-9760

INJECTION-PUMP ASSEMBLY