Information injection-pump assembly

ZEXEL

101402-9440

1014029440

Rating:

Service parts 101402-9440 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

ZEXEL

101402-9440

1014029440

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

37.4

36.4

38.4

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

D

Rack position

8+-0.5

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

11.5

10.5

12.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

60

70

Fixing the lever

*

Rack limit

*

Test data Ex:

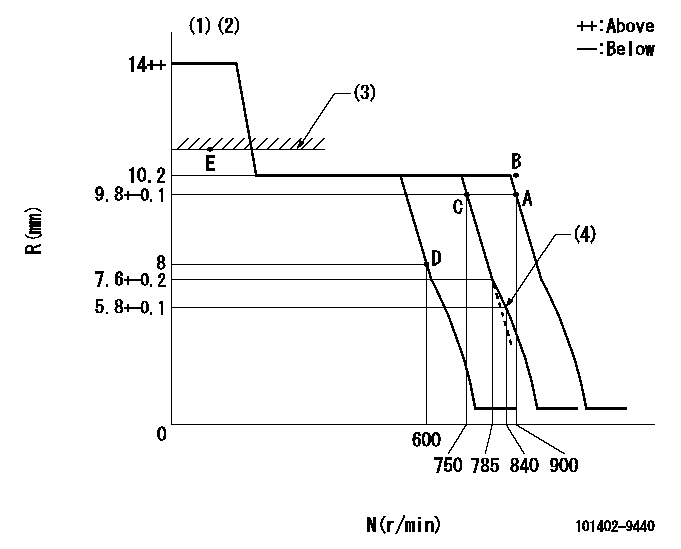

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

----------

K=11

----------

----------

K=11

----------

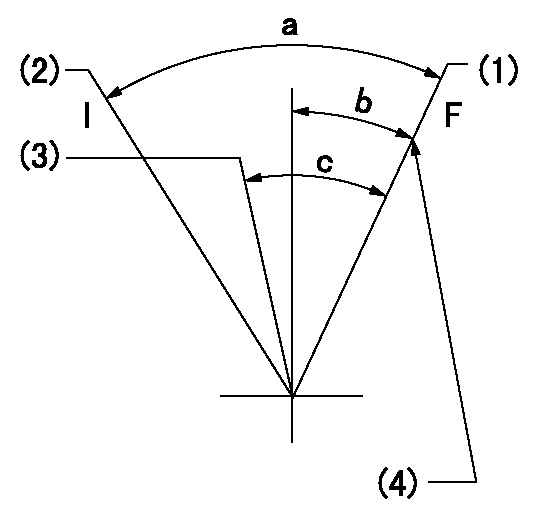

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa

(2)Stopper bolt setting

(3)When pump speed set at bb

(4)Stopper bolt setting

----------

aa=900r/min bb=750r/min

----------

a=11deg+-5deg b=2deg+-5deg c=5deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=11deg+-5deg b=2deg+-5deg c=5deg+-5deg

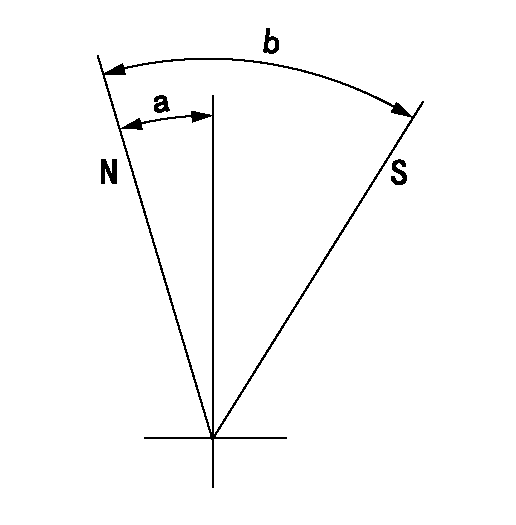

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=7deg+-5deg b=53deg+-5deg

----------

----------

a=7deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Illustration 2 g03507406

Typical example of the 456-6048 DPF TOOL GP

Use the following procedure to measure the amount of ash in the DPF:

Use a wire with the maximum diameter of 1.04140 mm (0.041 inch) or the 456-6048 DPF TOOL GP. Hold the wire or tool so that the end of the wire is just inside the cell approximately 6.35000 mm (0.25 inch).

Drop the wire into the cell of the DPF.

Mark the wire at the top of the cell where the wire exits from the DPF.

Measure the depth that the wire dropped by measuring from the mark to the bottom tip of the wire.

Record the measurement.

Illustration 3 g03021156

Top view of DPF

View of locations for recording measurements

(1) Weld line

Perform Steps 7.b through 7.e for all locations. Refer to Illustration 3 for the proper location for recording measurements.

Average the measurements and refer to Table 3 for the acceptable measurements.

Table 3

Filter Assembly Part Number New Service Kit Part Number Reman Service Kit Part Number - Upgrade to New Reman Service Kit Part Number - Cat Factory Cleaned Measured Wire Depth Requires Cleaning Acceptable Cleaned Measured Wire Depth

358-3658 358-3659 20R-0696 20R-5620 Less than 178 mm (7 inch) Greater than 279 mm (11 inch)

358-3661 358-3662 20R-0697 20R-5621 Less than 203 mm (8 inch) Greater than 305 mm (12 inch)

358-3663 358-3664 20R-0698 20R-5622 Less than 203 mm (8 inch) Greater than 305 mm (12 inch)

358-3666 358-3667 20R-0699 20R-5623 Less than 254 mm (10 inch) Greater than 343 mm (13.5 inch)

358-3668 358-3669 20R-0700 20R-5624 Less than 279 mm (11 inch) Greater than 394 mm (15.5 inch)

The DPF is ready to be returned to service. DPF Ash Service

Purpose

The engine ash model must be reset whenever the filter is cleaned or replaced. Reseting the ash model places the DPF ash volume back to the "Clean State". The resetting will allow the regeneration of the DPF to function properly. Cat ET Location

Connect to Cat ET.

Illustration 4 g02477962

Select "Service" from the top menu and highlight "Service Procedures".

Illustration 5 g02477961

From the "Service Procedures" menu, highlight "DPF Ash Service". Select "Start".

Illustration 6 g02495621

Illustration 7 g02477958

Select "Ash Service Reset" to start the test procedure.

Illustration 8 g02477960

Choose the correct replacement type of diesel particulate filter in the menu that appears. The types of replacements for the diesel particulate filter are the following:

"Field cleaned" A filter that has been cleaned and reapplied

"New" - A new filter replacement

"Remanufactured" - A remanufactured filter replacement

Illustration 9 g02495643

Illustration 10 g02478024

Once the reset is completed, a log of the reset is captured and visible as a new row of information in the DPF ash service screen.

Perform a "Manual DPF Regeneration" with Cat ET to reset the soot level