Information injection-pump assembly

BOSCH

9 400 614 012

9400614012

ZEXEL

101402-9390

1014029390

YANMAR

12990251400

12990251400

Rating:

Service parts 101402-9390 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

101402-9390

as INJECTION-PUMP ASSEMBLY

Include in #2:

104144-8002

as _

Cross reference number

BOSCH

9 400 614 012

9400614012

ZEXEL

101402-9390

1014029390

YANMAR

12990251400

12990251400

Zexel num

Bosch num

Firm num

Name

101402-9390

9 400 614 012

12990251400 YANMAR

INJECTION-PUMP ASSEMBLY

4TNE98 K

4TNE98 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

46.9

45.9

47.9

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

11.5

10.5

12.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

55

65

Fixing the lever

*

Rack limit

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

----------

K=16

----------

----------

K=16

----------

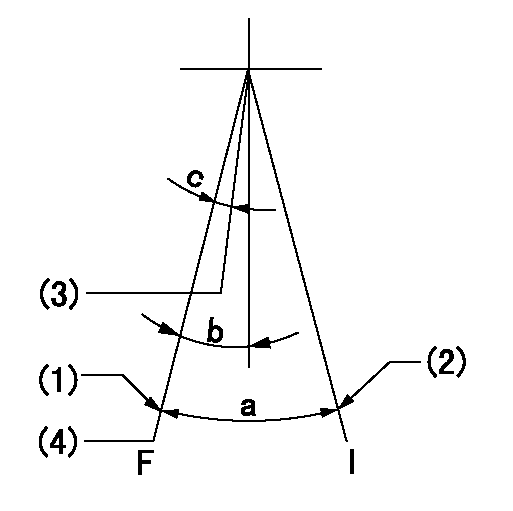

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Stopper bolt setting

(3)When pump speed set at aa

(4)Set the pump speed at bb.

----------

aa=750r/min bb=900r/min

----------

a=14deg+-5deg b=9deg+-5deg c=6deg+-5deg

----------

aa=750r/min bb=900r/min

----------

a=14deg+-5deg b=9deg+-5deg c=6deg+-5deg

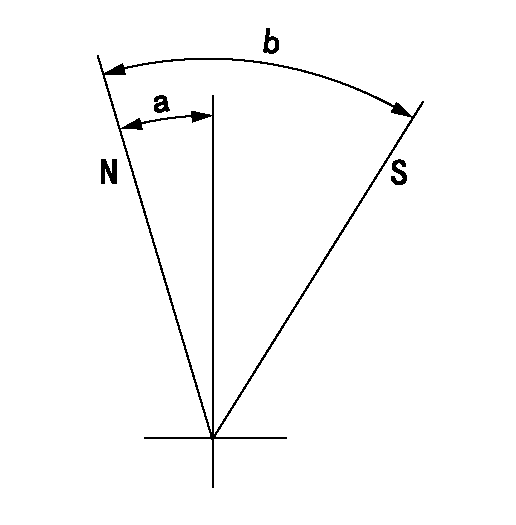

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=7deg+-5deg b=53deg+-5deg

----------

----------

a=7deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Install Tooling (E). Tighten Tooling (E) to a torque of 9 1 N m (80 9 lb in).Note: The pump will not function while Tooling (E) is installed. Running the fuel injection pump with the tooling installed will result in pump damage and system contamination.

Illustration 6 g02025176

Disconnect harness assemblies (3).

Remove nut (5) and remove the clamp assembly. Discard the clamp assembly.

Loosen nuts (4) and (7). Remove the fuel line and discard the fuel line.

Disconnect hose assembly (6).

Illustration 7 g02029098

Disconnect tube assemblies (9).

Disconnect hose assemblies (10) and (11).

Remove bolts (8).

Illustration 8 g02029093

Disconnect tube assembly (12).

Illustration 9 g02025262

Remove bolts (13) and remove fuel pump (14).Installing the Fuel Injection Pump

Note: Check the O-ring seals, the gaskets, and the seals for wear or for damage. Replace the components, if necessary.

Illustration 10 g02385860

Service replacement pump

Note: Service replacement pump is shipped pinned with warning tag (Z) installed under pinch bolt (E).

Illustration 11 g02025262

Position fuel pump (14) and install bolts (13).

Illustration 12 g02029093

Connect tube assembly (12).

Illustration 13 g02029098

Install bolts (8).

Connect tube assembly (9) and connect both hose assemblies (10) and (11).

Illustration 14 g02025176Note: During installation, make sure that the fuel line caps remain in position until the fuel line is positioned near the corresponding ports in order to prevent contamination. Ensure that the areas around the rail and fuel lines are thoroughly clean before continuing this procedure. If any parts are worn or damaged, use new parts for replacement. Cleanliness is an important factor. Ensure that no debris gets introduced into the fuel system during the installation procedure. If any parts are worn or damaged, use new parts for replacement.

Connect harness assemblies (3).

Install a new fuel line. Hand tighten nuts (4) and (7).

Position the clamp assembly and install nut (5). Hand tighten the nut. Failure to place the grommet correctly on the fuel line could result in a failed fuel line.Note: Ensure that the fuel lines are centered in the nuts prior to tightening. Do not use excessive force or bending in order to assemble the fuel lines.

Tighten nut (4) at the fuel rail to a torque of 27 3 N m (239 27 lb in).

Tighten nut (7) to a torque of 27 3 N m (239 27 lb in).

Tighten nut (5) to a torque of 12 3 N m (105 27 lb in).

Illustration 15 g02351995

Remove Tooling (E) and warning tag (Z).Note: The pump will not function while Tooling (E) is installed. Running the fuel injection pump with the tooling installed will result in pump damage and system contamination.

Illustration 16 g02351981

Install O-ring seal (2) and plug (1). Tighten the plug to a torque of 9 1 N m (80 9 lb in).

Illustration 17 g02112896

Remove all tooling. Reinstall plug (X) into the timing hole that is located in the flywheel housing.

Connect Caterpillar Electronic Technician (ET). Perform a “Fuel System Functional Test ”and a “Fuel System Verification Test”.

Have questions with 101402-9390?

Group cross 101402-9390 ZEXEL

Mitsubishi-Heav

Mitsubishi-Heav

Mitsubishi-Heav

Mitsubishi-Heav

Yanmar

Yanmar

Yanmar

Yanmar

101402-9390

9 400 614 012

12990251400

INJECTION-PUMP ASSEMBLY

4TNE98

4TNE98