Information injection-pump assembly

ZEXEL

101402-9080

1014029080

YANMAR

12643051010

12643051010

Rating:

Service parts 101402-9080 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

ZEXEL

101402-9080

1014029080

YANMAR

12643051010

12643051010

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-4-3

Pre-stroke

mm

3.8

3.75

3.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 90 89.5 90.5

Cyl.1-2 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cal 1-3 deg. 270 269.5 270.5

Cal 1-3 deg. 270 269.5 270.5

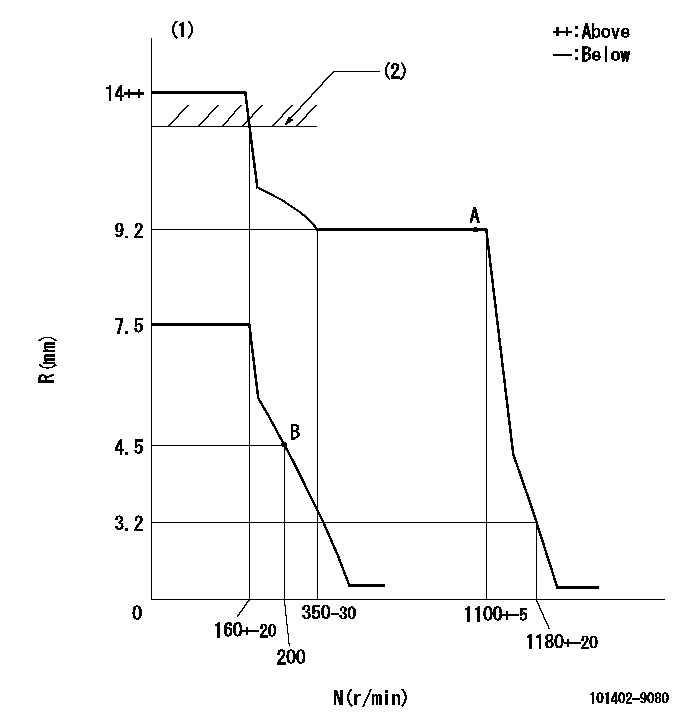

Injection quantity adjustment

Adjusting point

A

Rack position

9.2

Pump speed

r/min

1100

1100

1100

Each cylinder's injection qty

mm3/st.

128.2

126.3

130.1

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

4.5+-0.5

Pump speed

r/min

200

200

200

Each cylinder's injection qty

mm3/st.

16

15

17

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

----------

K=4 RAL=11.6+0.2mm

----------

----------

K=4 RAL=11.6+0.2mm

----------

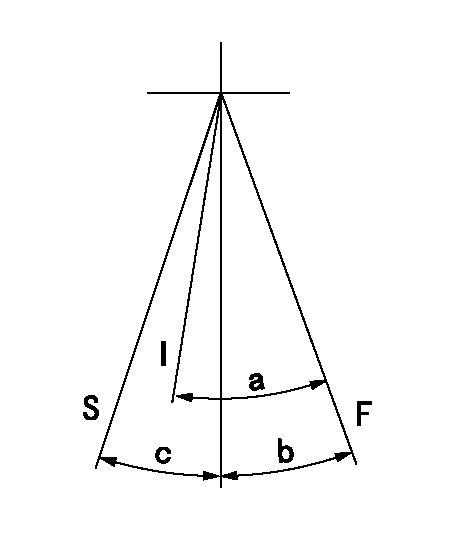

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=35deg+-5deg b=10deg+-5deg c=32deg+-3deg

----------

----------

a=35deg+-5deg b=10deg+-5deg c=32deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=(20deg) b=(53deg)

----------

----------

a=(20deg) b=(53deg)

Information:

START BY:a. remove fuel filter and base1. Drain the coolant from the engine.

Do not disconnect the air line from the compressor governor until the air pressure is zero.

2. Loosen the bleed valve and release the air pressure in the air tank. 3. Disconnect air compressor line (1) and fuel ratio control line (2) from the aftercooler housing. 4. Remove four turbocharger tube adapter to aftercooler housing bolts (3), nuts and cover. Loosen turbocharger compressor housing clamp (4), and rotate turbocharger tube (5) out of the way of the aftercooler housing. 5. Fasten tooling (A) and a hoist to aftercooler housing (6). Remove bolts (7) that hold the aftercooler housing to the cylinder head assembly. Remove the aftercooler housing from the engine. The weight is 36 kg (80 lb.).Install Aftercooler Housing

1. Install new O-ring seals (1) on the aftercooler water inlet and outlet pipes. Lubricate the O-ring seals with clean engine oil. Put new gaskets in position on the cylinder head assembly.2. Fasten tooling (A) and a hoist to aftercooler housing (2), and put the aftercooler housing in position on the water pipes and cylinder head assembly.3. Put 9S3263 Thread Lock on the threads of the bolts, and install the bolts that hold the aftercooler housing to the cylinder head assembly. 4. Rotate turbocharger tube (3) into position. Place a gasket between the aftercooler housing and adapter, and install four bolts and nuts that hold it. Tighten turbocharger clamp nut (4) to a torque of 18 3 N m (13 2 lb.ft.). Lightly hit all around the clamp with a soft faced hammer, and tighten the clamp nut again to the same torque value. 5. Connect air compressor line (5) and fuel ratio control line (6).6. Fill engine with coolant to the correct level. See the Maintenance Guide.END BY:a. install fuel filter and base

Do not disconnect the air line from the compressor governor until the air pressure is zero.

2. Loosen the bleed valve and release the air pressure in the air tank. 3. Disconnect air compressor line (1) and fuel ratio control line (2) from the aftercooler housing. 4. Remove four turbocharger tube adapter to aftercooler housing bolts (3), nuts and cover. Loosen turbocharger compressor housing clamp (4), and rotate turbocharger tube (5) out of the way of the aftercooler housing. 5. Fasten tooling (A) and a hoist to aftercooler housing (6). Remove bolts (7) that hold the aftercooler housing to the cylinder head assembly. Remove the aftercooler housing from the engine. The weight is 36 kg (80 lb.).Install Aftercooler Housing

1. Install new O-ring seals (1) on the aftercooler water inlet and outlet pipes. Lubricate the O-ring seals with clean engine oil. Put new gaskets in position on the cylinder head assembly.2. Fasten tooling (A) and a hoist to aftercooler housing (2), and put the aftercooler housing in position on the water pipes and cylinder head assembly.3. Put 9S3263 Thread Lock on the threads of the bolts, and install the bolts that hold the aftercooler housing to the cylinder head assembly. 4. Rotate turbocharger tube (3) into position. Place a gasket between the aftercooler housing and adapter, and install four bolts and nuts that hold it. Tighten turbocharger clamp nut (4) to a torque of 18 3 N m (13 2 lb.ft.). Lightly hit all around the clamp with a soft faced hammer, and tighten the clamp nut again to the same torque value. 5. Connect air compressor line (5) and fuel ratio control line (6).6. Fill engine with coolant to the correct level. See the Maintenance Guide.END BY:a. install fuel filter and base