Information injection-pump assembly

BOSCH

F 019 Z10 464

f019z10464

ZEXEL

101402-8330

1014028330

ISUZU

8980038750

8980038750

Rating:

Service parts 101402-8330 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-97238-978-0

12.

Open Pre:MPa(Kqf/cm2)

18.1(185)

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z10 464

f019z10464

ZEXEL

101402-8330

1014028330

ISUZU

8980038750

8980038750

Zexel num

Bosch num

Firm num

Name

F 019 Z10 464

8980038750 ISUZU

INJECTION-PUMP ASSEMBLY

4JG1-T * K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4JG1-T * K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-2

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

9

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

84

83

85

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.5+-0.5

Pump speed

r/min

575

575

575

Average injection quantity

mm3/st.

11.5

9.5

13.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

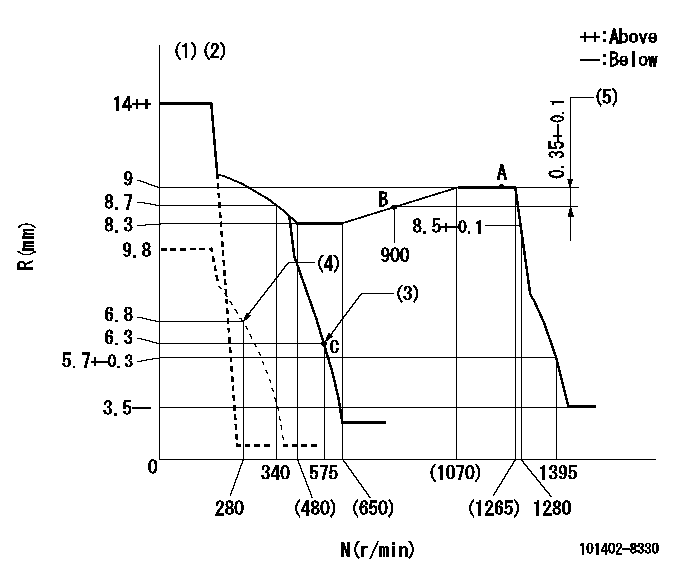

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Main spring setting

(4)Set idle sub-spring

(5)Rack difference between N = N1 and N = N2

----------

K=14 N1=1250r/min N2=900r/min

----------

----------

K=14 N1=1250r/min N2=900r/min

----------

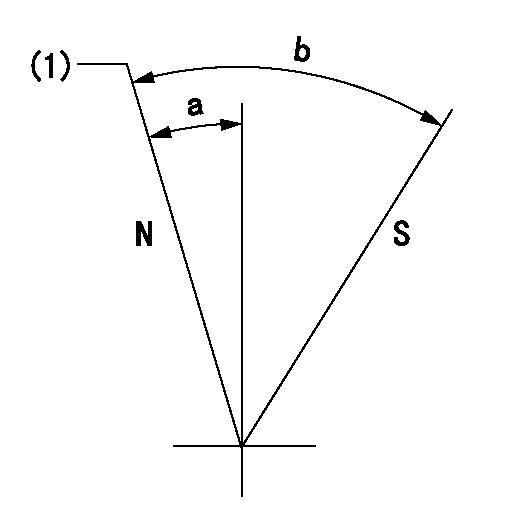

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Stopper bolt setting

----------

----------

a=14deg+-5deg b=22deg+-5deg c=31deg+-3deg

----------

----------

a=14deg+-5deg b=22deg+-5deg c=31deg+-3deg

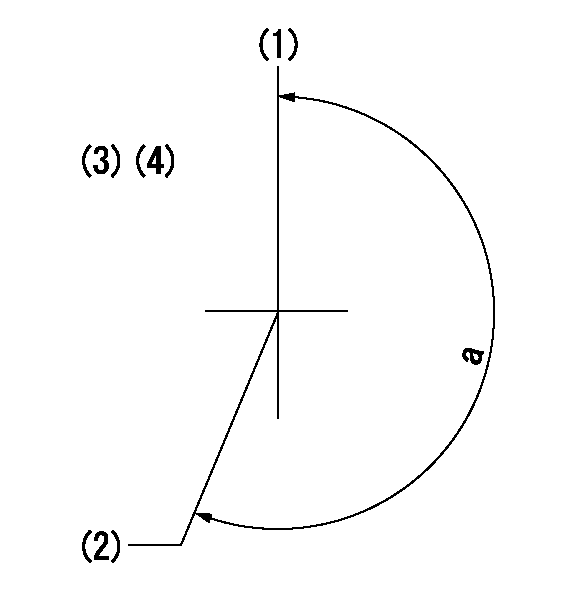

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=2.5deg+-5deg b=53deg+-5deg

----------

----------

a=2.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'W' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=6deg

----------

a=(210deg)

----------

aa=6deg

----------

a=(210deg)

Information:

1. Remove line (1) from the fuel ratio control. Remove two bolts (3), and remove solenoid (2) from the governor housing.2. Disconnect throttle linkage (4) from the lever assembly on the side of the governor housing. (A test application is shown in the photo.)3. Remove two bolts (5) from the front of the governor housing. Remove eight bolts (6), and remove governor housing (7). 4. Remove two bolts that hold fuel ratio control (8) to the governor housing. Unscrew the fuel ratio control from shaft (9) and remove it.5. Remove plug and seal (10) from the governor housing. 6. Remove two bolts (12) that hold lock (11) and flange (14) on fuel ratio control (8). Remove lock (11), flange (14), and O-ring seal (13) from the fuel ratio control.7. Check the condition of O-ring seal (13). If it is worn or damaged, make a replacement with a new part. 8. Remove ring (19) from the end of shaft (15). Remove lever assembly (18), spring (17), lever (16), spacer (21) and shaft (15) from the governor housing.9. Remove pin (20) from lever assembly (18) with a hammer and punch. Remove shaft (9) from the lever assembly. The following steps are for the installation of the fuel ratio control.10. Position shaft (9) in lever assembly (18) and install it with pin (20) using a hammer and punch.11. Install shaft (15), spacer (21), lever (16), spring (17) and lever assembly (18) in the governor housing. Install ring (19) on the end of shaft (15).12. Install O-ring seal (13) on fuel ratio control (8). Install flange (14) and lock (11) on the fuel ratio control with bolts (12).13. Install seal and plug (10) in the governor housing.14. Check the condition of the four O-ring seals on top of the governor housing where the fuel ratio control mounts. If any of the seals are worn or damaged, make a replacement with new parts.15. Screw fuel ratio control (8) onto shaft (9) approximately six turns. Install the fuel ratio control with the two bolts that hold it to the governor housing.16. Position governor housing (7), and install two bolts (5) on the front of the governor housing. Install eight bolts (6).17. Connect throttle linkage (4) to the lever assembly on the side of the governor housing.18. Install solenoid (2) with bolts (3). Install line (1) on the fuel ratio control.19. Make an adjustment to the fuel ratio control. See the topic, FUEL RATIO CONTROL ADJUSTMENT in the TESTING AND ADJUSTING section of this Module.