Information injection-pump assembly

BOSCH

9 400 619 710

9400619710

ZEXEL

101402-8300

1014028300

ISUZU

8973586960

8973586960

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump 8-97358-696-0 for Isuzu Engine 4JG1 4JG1T

100% Apollo part number:8-97358-696-0 || application: for Isuzu Engine 4JG1 4JG1T

100% Apollo part number:8-97358-696-0 || application: for Isuzu Engine 4JG1 4JG1T

ZGZJYBL Fuel Injection Pump For Isuzu 4JG1 4JG1T Engine 9400619710 8-97358-696-0

ZGZJYBL Item Name:Fuel Injection Pump || Item Number:8-97358-696-0, 8973586960, 9400619710, 101402-8300, 1014028300 || Application:Fit for Isuzu Engine: 4JG1, 4JG1T, A8-4JG1T, DD-4JG1 || Attention: If you are unsure if the product is suitable for your machine model. In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please carefully check the product image and part number to ensure that it is the product you want. || Tip: If you need any other parts, please contact us - we are a professional sales team and have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

ZGZJYBL Item Name:Fuel Injection Pump || Item Number:8-97358-696-0, 8973586960, 9400619710, 101402-8300, 1014028300 || Application:Fit for Isuzu Engine: 4JG1, 4JG1T, A8-4JG1T, DD-4JG1 || Attention: If you are unsure if the product is suitable for your machine model. In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please carefully check the product image and part number to ensure that it is the product you want. || Tip: If you need any other parts, please contact us - we are a professional sales team and have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

Service parts 101402-8300 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-97358-697-0

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 619 710

9400619710

ZEXEL

101402-8300

1014028300

ISUZU

8973586960

8973586960

Zexel num

Bosch num

Firm num

Name

101402-8300

9 400 619 710

8973586960 ISUZU

INJECTION-PUMP ASSEMBLY

4JG1-T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4JG1-T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-2

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

7.9

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

46.8

45.8

47.8

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.2+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

11.5

9.5

13.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

9.2++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

110

105

115

Fixing the lever

*

Rack limit

*

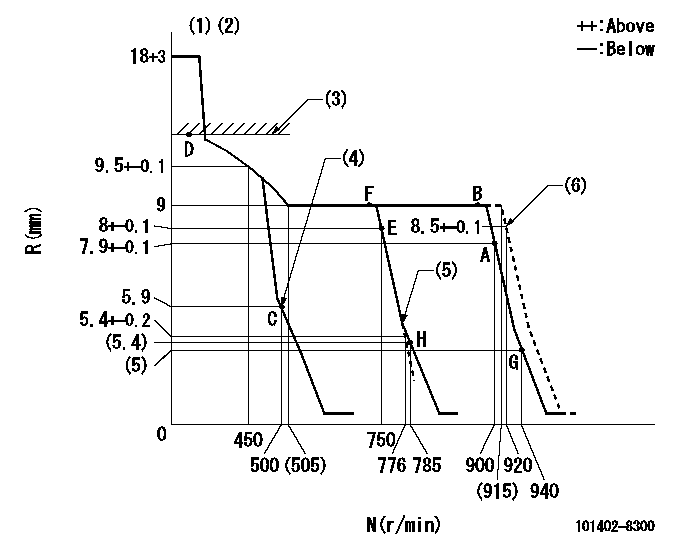

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Main spring setting

(5)Idle sub spring setting: L1.

(6)Set at delivery

----------

K=8 L1=6.2+-0.1mm

----------

----------

K=8 L1=6.2+-0.1mm

----------

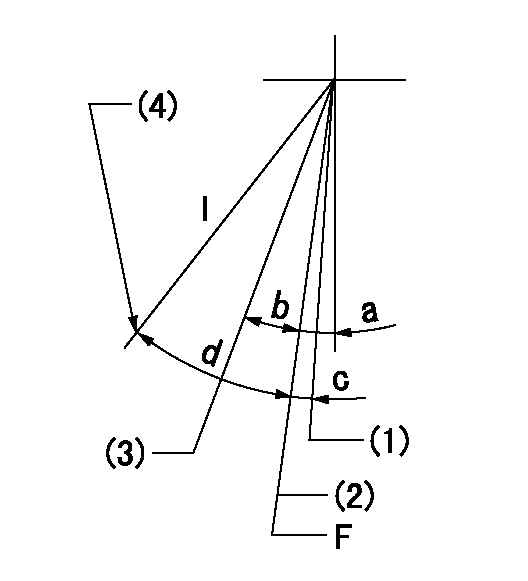

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)When pump speed set at bb

(3)When speed is set at cc.

(4)Stopper bolt setting

----------

aa=920r/min bb=900r/min cc=750r/min

----------

a=3deg+-5deg b=5deg+-5deg c=(1deg) d=15deg+-5deg

----------

aa=920r/min bb=900r/min cc=750r/min

----------

a=3deg+-5deg b=5deg+-5deg c=(1deg) d=15deg+-5deg

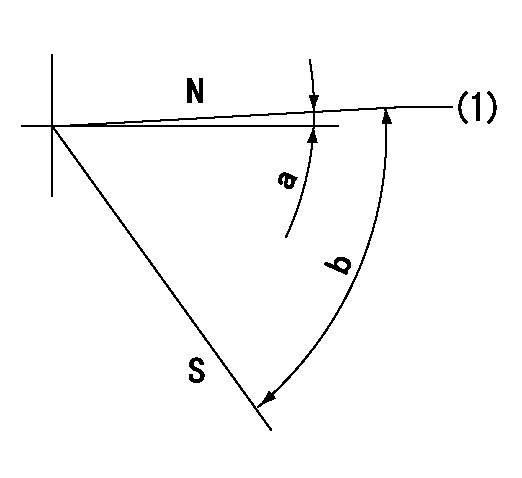

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=3.5deg+-5deg b=53deg+-5deg

----------

----------

a=3.5deg+-5deg b=53deg+-5deg

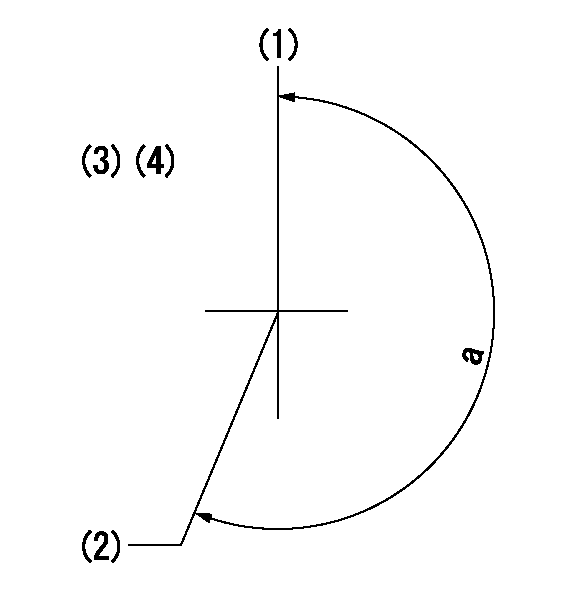

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'W' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=5deg

----------

a=(210deg)

----------

aa=5deg

----------

a=(210deg)

Information:

START BY:a. remove valve coversb. remove fuel injection lines 1. Use tool (A) and a 5P328 crowfoot wrench (7/8") to loosen the fuel injection line nut at the nozzle end.

Do not let the tops of the fuel nozzles turn when the fuel lines are loosened. The nozzles will be damaged if the top of the nozzles turn in the body.

2. Use tool (B) to loosen the nut at the fuel injection line adapter end. Remove inner fuel injection lines (1). Install plugs in the fuel injection nozzles. 3. Remove the nut that holds the adapters to the cylinder head assembly. Remove fuel injection line adapters (2).Install Fuel Injection Line Adapters

1. Check the condition of O-ring seal (1) on fuel injection line adapter (2) for damage. Make a replacement if necessary.2. Lubricate O-ring seal (1) with clean engine oil. Install fuel injection line adapter (2). Tighten the retaining nut to a torque of 13.6 2.7 N m (10 2 lb.ft.). 3. Check the condition of the O-ring seal on inner fuel line (3) for damage, and make a replacement if necessary. Install inner fuel line (3).

Do not let the tops of the fuel nozzles turn when the fuel lines are tightened. The nozzles will be damaged if the top of the nozzles turn in the body.

4. Use tooling (A) to tighten the inner fuel line nuts to a torque of 40 7 N m (30 5 lb.ft.).END BY:a. install fuel injection linesb. install valve covers

Do not let the tops of the fuel nozzles turn when the fuel lines are loosened. The nozzles will be damaged if the top of the nozzles turn in the body.

2. Use tool (B) to loosen the nut at the fuel injection line adapter end. Remove inner fuel injection lines (1). Install plugs in the fuel injection nozzles. 3. Remove the nut that holds the adapters to the cylinder head assembly. Remove fuel injection line adapters (2).Install Fuel Injection Line Adapters

1. Check the condition of O-ring seal (1) on fuel injection line adapter (2) for damage. Make a replacement if necessary.2. Lubricate O-ring seal (1) with clean engine oil. Install fuel injection line adapter (2). Tighten the retaining nut to a torque of 13.6 2.7 N m (10 2 lb.ft.). 3. Check the condition of the O-ring seal on inner fuel line (3) for damage, and make a replacement if necessary. Install inner fuel line (3).

Do not let the tops of the fuel nozzles turn when the fuel lines are tightened. The nozzles will be damaged if the top of the nozzles turn in the body.

4. Use tooling (A) to tighten the inner fuel line nuts to a torque of 40 7 N m (30 5 lb.ft.).END BY:a. install fuel injection linesb. install valve covers

Have questions with 101402-8300?

Group cross 101402-8300 ZEXEL

Isuzu

101402-8300

9 400 619 710

8973586960

INJECTION-PUMP ASSEMBLY

4JG1-T

4JG1-T