Information injection-pump assembly

BOSCH

9 400 619 485

9400619485

ZEXEL

101402-8290

1014028290

ISUZU

8973710430

8973710430

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Car fuel pump assembly, Injection Pump For 4BG1T 8-97371043-0 101402-8290 101041-8900 Compatible For ISUZU(Silver)

ZTUVUNVA The design of the oil outlet is exquisite and reasonable, which avoids carbon deposition at the oil outlet and effectively prolongs the service life. || Reduce fuel consumption, improve jitter and accelerate smoothly. || The oil meter is accurate, which can solve the problems of abnormal oil consumption, misfire and no power. || Solve problems such as abnormal fuel meter data. || Sufficient oil return flow ensures stable pressure and sufficient cooling of the fuel system.

ZTUVUNVA The design of the oil outlet is exquisite and reasonable, which avoids carbon deposition at the oil outlet and effectively prolongs the service life. || Reduce fuel consumption, improve jitter and accelerate smoothly. || The oil meter is accurate, which can solve the problems of abnormal oil consumption, misfire and no power. || Solve problems such as abnormal fuel meter data. || Sufficient oil return flow ensures stable pressure and sufficient cooling of the fuel system.

Car fuel pump assembly, Injection Pump For 4BG1T 8-97371043-0 101402-8290 101041-8900 Compatible For ISUZU(Black)

ZTUVUNVA The design of the oil outlet is exquisite and reasonable, which avoids carbon deposition at the oil outlet and effectively prolongs the service life. || Reduce fuel consumption, improve jitter and accelerate smoothly. || The oil meter is accurate, which can solve the problems of abnormal oil consumption, misfire and no power. || Solve problems such as abnormal fuel meter data. || Sufficient oil return flow ensures stable pressure and sufficient cooling of the fuel system.

ZTUVUNVA The design of the oil outlet is exquisite and reasonable, which avoids carbon deposition at the oil outlet and effectively prolongs the service life. || Reduce fuel consumption, improve jitter and accelerate smoothly. || The oil meter is accurate, which can solve the problems of abnormal oil consumption, misfire and no power. || Solve problems such as abnormal fuel meter data. || Sufficient oil return flow ensures stable pressure and sufficient cooling of the fuel system.

Compatible with Isuzu Engine 4HF1 4BG1T Fits Fuel Injection Pump 101402-8290 8-97371043-0 101041-8900

EWAIDI Part Number: 101402-8290 8-97371043-0 101041-8900 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || The 4BG1T diesel engine is a durable, high-performance model with low emissions. Featuring a 4.0 liter displacement and turbocharged technology, it offers superb fuel efficiency and reliability. Ideal for powering generators, construction equipment, and agricultural machinery, this engine is a cost-effective choice for demanding tasks. Its compact design and easy maintenance make it popular worldwide. || Suitable for use with Isuzu engines 4HF1 and 4BG1T. || Included in the package are one piece of Fuel Injection Pump with the following part numbers: 101402-8290, 8-97371043-0, and 101041-8900.

EWAIDI Part Number: 101402-8290 8-97371043-0 101041-8900 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || The 4BG1T diesel engine is a durable, high-performance model with low emissions. Featuring a 4.0 liter displacement and turbocharged technology, it offers superb fuel efficiency and reliability. Ideal for powering generators, construction equipment, and agricultural machinery, this engine is a cost-effective choice for demanding tasks. Its compact design and easy maintenance make it popular worldwide. || Suitable for use with Isuzu engines 4HF1 and 4BG1T. || Included in the package are one piece of Fuel Injection Pump with the following part numbers: 101402-8290, 8-97371043-0, and 101041-8900.

You can express buy:

USD 1041.61

29-06-2025

29-06-2025

4BG1T 4BG1 Fuel inje ction pump 8-97371043-0 101402-8290 101041-8900 8973710430 For ISUZU ZEXEL 4BG1T

Images:

USD 1218.59

[01-Jul-2025]

USD 853.69

[14-Jun-2025]

USD 2369.82

[14-Jun-2025]

Service parts 101402-8290 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 619 485

9400619485

ZEXEL

101402-8290

1014028290

ISUZU

8973710430

8973710430

Zexel num

Bosch num

Firm num

Name

101402-8290

9 400 619 485

8973710430 ISUZU

INJECTION-PUMP ASSEMBLY

4BG1-T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4BG1-T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

94

92.9

95.1

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.3+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

12

10.6

13.4

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

9.1++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

120

130

Fixing the lever

*

Rack limit

*

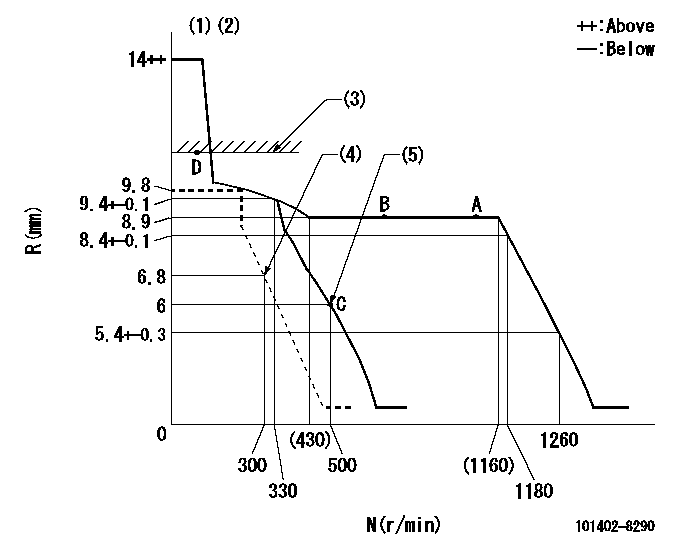

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=16

----------

----------

K=16

----------

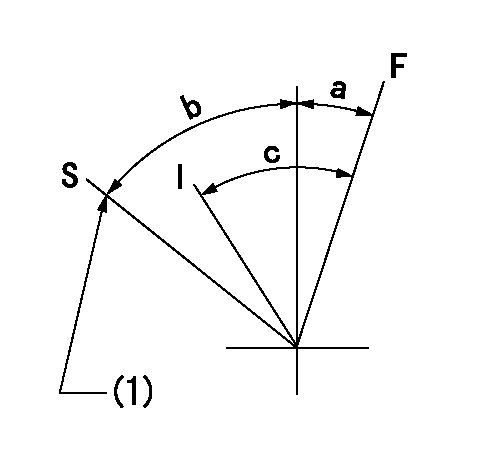

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Stopper bolt setting

----------

----------

a=7deg+-5deg b=35deg+-5deg c=21deg+-5deg

----------

----------

a=7deg+-5deg b=35deg+-5deg c=21deg+-5deg

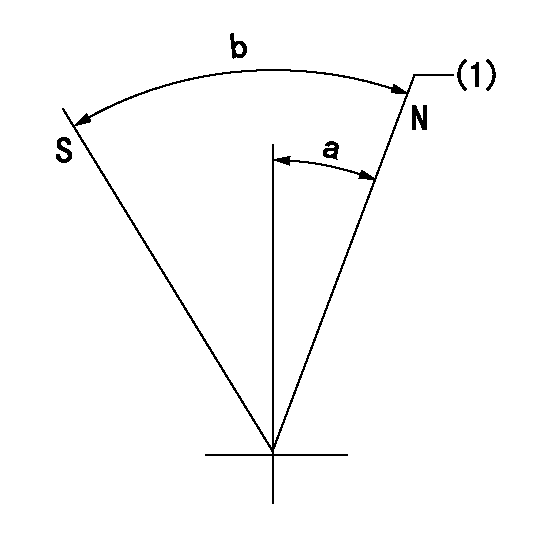

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=13deg+-5deg b=53deg+-5deg

----------

----------

a=13deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=9deg

----------

a=(100deg)

----------

aa=9deg

----------

a=(100deg)

Information:

Bearings

Anti-Friction Bearings

When an anti-friction bearing is removed, cover it to keep out dirt and abrasives. Wash the bearings in nonflammable cleaning solution and allow them to drain dry. The bearings may be dried with compressed air, but DO NOT SPIN THE BEARING. Discard the bearings if the races and balls or rollers are pitted, scored or burned. If the bearing is serviceable, coat it with oil and wrap it in clean paper. DO NOT unwrap new bearings until time of installation.The life of an anti-friction bearing will be shortened if not properly lubricated.Double Row, Tapered Roller

Double row, tapered roller bearings are precision fit during manufacture and the components are not interchangeable. The cups, cones and spacers are usually etched with the same serial number and letter designator. If no letter designators are found, wire the components together to assure correct installation. Reusable bearing components should be installed in their original positions.Heating Bearings

Bearings which require expansion for installation should be heated in oil not to exceed 121°C (250°F). When more than one part is heated to aid in assembly, they must be allowed to cool and then pressed together again. Parts often separate as they cool and shrink.Installation

Lubricate new or used bearings before installation. Bearings that are to be preloaded must have a film of oil over the entire assembly to obtain accurate preloading. When installing a bearing, spacer or washer against a shoulder on a shaft, be sure the chamfered side is toward the shoulder. When pressing bearings into a retainer or bore, apply pressure to the outer race. If the bearing is pressed on the shaft, apply pressure on the inner race.Preload

Preload is an initial force placed on the bearing at the time of assembly.Determine preload or end clearance form the Specifications Section of this Service Manual. Care should be exercised in applying preload. Misapplication of preload to bearings requiring end clearance can result in bearing failure.Sleeve Bearings

DO NOT INSTALL SLEEVE BEARINGS WITH A HAMMER. Use a press, if possible and apply the pressure directly in line with the bore. If it is necessary to drive on a bearing, use a driver or a bar with a smooth flat end. If a sleeve bearing has an oil hole, align it with the oil hole in the mating part.

Anti-Friction Bearings

When an anti-friction bearing is removed, cover it to keep out dirt and abrasives. Wash the bearings in nonflammable cleaning solution and allow them to drain dry. The bearings may be dried with compressed air, but DO NOT SPIN THE BEARING. Discard the bearings if the races and balls or rollers are pitted, scored or burned. If the bearing is serviceable, coat it with oil and wrap it in clean paper. DO NOT unwrap new bearings until time of installation.The life of an anti-friction bearing will be shortened if not properly lubricated.Double Row, Tapered Roller

Double row, tapered roller bearings are precision fit during manufacture and the components are not interchangeable. The cups, cones and spacers are usually etched with the same serial number and letter designator. If no letter designators are found, wire the components together to assure correct installation. Reusable bearing components should be installed in their original positions.Heating Bearings

Bearings which require expansion for installation should be heated in oil not to exceed 121°C (250°F). When more than one part is heated to aid in assembly, they must be allowed to cool and then pressed together again. Parts often separate as they cool and shrink.Installation

Lubricate new or used bearings before installation. Bearings that are to be preloaded must have a film of oil over the entire assembly to obtain accurate preloading. When installing a bearing, spacer or washer against a shoulder on a shaft, be sure the chamfered side is toward the shoulder. When pressing bearings into a retainer or bore, apply pressure to the outer race. If the bearing is pressed on the shaft, apply pressure on the inner race.Preload

Preload is an initial force placed on the bearing at the time of assembly.Determine preload or end clearance form the Specifications Section of this Service Manual. Care should be exercised in applying preload. Misapplication of preload to bearings requiring end clearance can result in bearing failure.Sleeve Bearings

DO NOT INSTALL SLEEVE BEARINGS WITH A HAMMER. Use a press, if possible and apply the pressure directly in line with the bore. If it is necessary to drive on a bearing, use a driver or a bar with a smooth flat end. If a sleeve bearing has an oil hole, align it with the oil hole in the mating part.

Have questions with 101402-8290?

Group cross 101402-8290 ZEXEL

Isuzu

101402-8290

9 400 619 485

8973710430

INJECTION-PUMP ASSEMBLY

4BG1-T

4BG1-T