Information injection-pump assembly

BOSCH

9 400 612 295

9400612295

ZEXEL

101402-7871

1014027871

ISUZU

8972633951

8972633951

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Aftermarket Fuel Injection Pump 8972633951 Fit Intended For Engine 4JG1 Excavator ZX60 ZX70 ZX75UR ZX75URT ZX75US ZX80LCK ZX80SB ZX85US Z 75US Z 80

Generic

Generic

Aftermarket Fuel Injection Pump 8972633952 8972633951 Fit Intended For Engine 4JG1 Excavator 75C 80C

Generic

Generic

8-97253022-1 8-97263395-1 104746-5051 101402-7871 4JG2 4JG1 Diesel Injection Pump Parts

VDGOGHCN Precisely match the car model, easy to install, without complicated debugging, and can be used by direct replacement. || It can respond quickly to different working conditions of the engine, adjust the fuel injection quantity in time and ensure the smooth operation of the engine. || Accurately control the fuel injection quantity and time, so as to make the fuel burn fully, reduce the fuel consumption and improve the dynamic performance of the vehicle. || It has strong pressure output ability, which ensures that fuel can enter the engine combustion chamber accurately and efficiently, and improves combustion efficiency. || Advanced manufacturing technology and high-quality materials are adopted to effectively reduce vibration and noise during operation and ensure the stability of fuel injection process.

VDGOGHCN Precisely match the car model, easy to install, without complicated debugging, and can be used by direct replacement. || It can respond quickly to different working conditions of the engine, adjust the fuel injection quantity in time and ensure the smooth operation of the engine. || Accurately control the fuel injection quantity and time, so as to make the fuel burn fully, reduce the fuel consumption and improve the dynamic performance of the vehicle. || It has strong pressure output ability, which ensures that fuel can enter the engine combustion chamber accurately and efficiently, and improves combustion efficiency. || Advanced manufacturing technology and high-quality materials are adopted to effectively reduce vibration and noise during operation and ensure the stability of fuel injection process.

You can express buy:

USD 426.22

19-05-2025

19-05-2025

8-97253022-1 8-97263395-1 104746-5051 101402-7871 4JG2 4JG1 Diesel Injection Pump Parts

Images:

USD 411.32

[13-May-2025]

USD 406.7

[13-May-2025]

Service parts 101402-7871 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-97238-978-0

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 612 295

9400612295

ZEXEL

101402-7871

1014027871

ISUZU

8972633951

8972633951

Zexel num

Bosch num

Firm num

Name

101402-7871

9 400 612 295

8972633951 ISUZU

INJECTION-PUMP ASSEMBLY

4JG1 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4JG1 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-2

Pre-stroke

mm

2.6

2.55

2.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.2

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

61

60

62

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.8+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

17

15

19

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

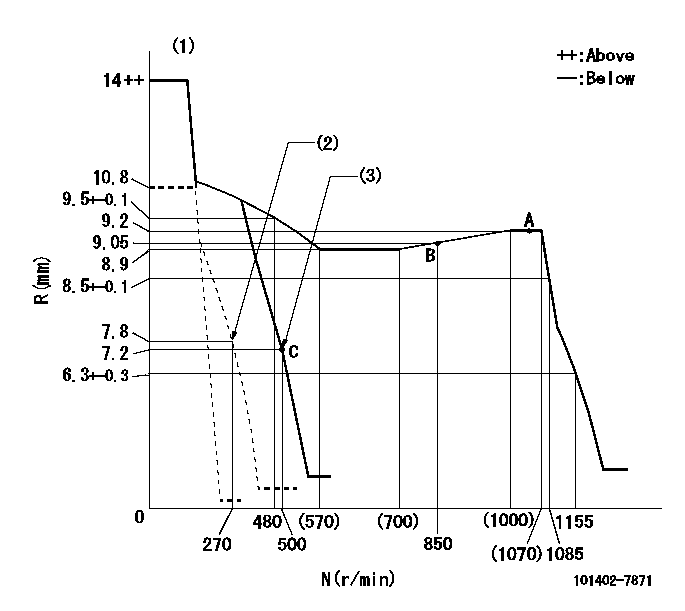

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Set idle sub-spring

(3)Main spring setting

----------

K=9

----------

----------

K=9

----------

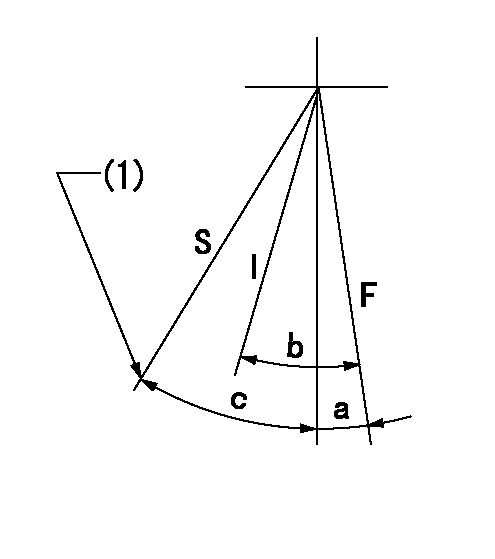

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Stopper bolt setting

----------

----------

a=1deg+-5deg b=17deg+-5deg c=31deg+-3deg

----------

----------

a=1deg+-5deg b=17deg+-5deg c=31deg+-3deg

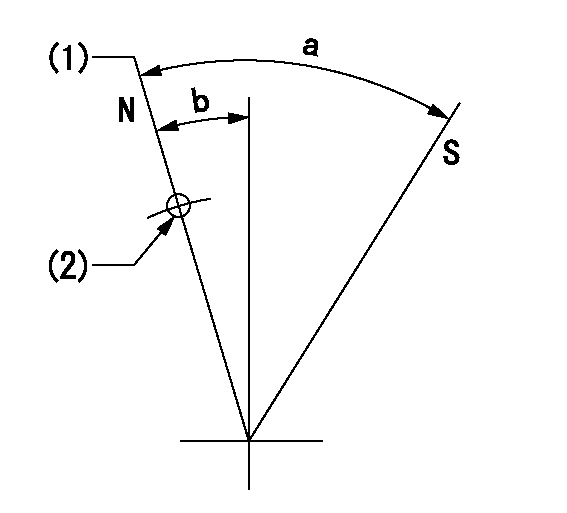

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Use the hole at R = aa

----------

aa=25mm

----------

a=53deg+-5deg b=2.5deg+-5deg

----------

aa=25mm

----------

a=53deg+-5deg b=2.5deg+-5deg

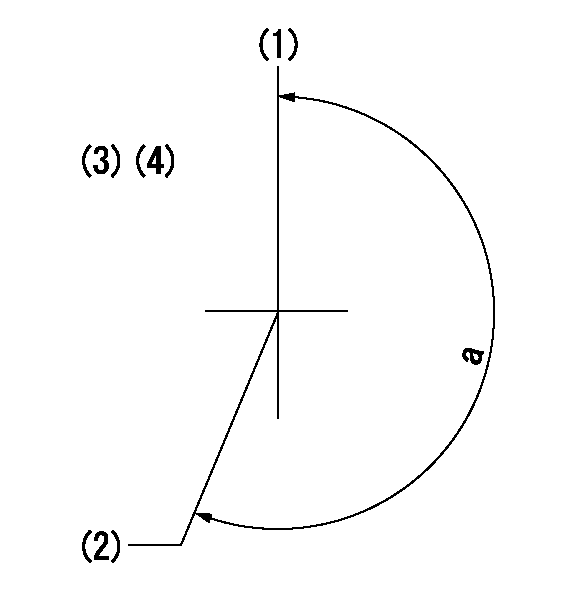

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'W' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(210deg)

----------

aa=10deg

----------

a=(210deg)

Information:

Engine Runs Smoothly

Recommended Procedure

1. Engine Used in a Lug Condition ... "Lugging" (when the truck is used in a gear too high for engine rpm to go up as accelerator pedal is pushed farther down, or when the truck is used in a gear where engine rpm goes down with accelerator pedal at maximum travel) the engine causes a reduction in the intake of air with full fuel delivery to the cylinders. Because there is not enough air to burn all the fuel, the fuel that is not used comes out the exhaust as black smoke. To prevent lugging the engine, use a gear where engine can have "acceleration" (increase in speed) under load.2. Dirty Air Cleaner ... If the air cleaner has a restriction indicator, see if the red piston is in view. If there is no restriction indicator, restriction

Recommended Procedure

1. Engine Used in a Lug Condition ... "Lugging" (when the truck is used in a gear too high for engine rpm to go up as accelerator pedal is pushed farther down, or when the truck is used in a gear where engine rpm goes down with accelerator pedal at maximum travel) the engine causes a reduction in the intake of air with full fuel delivery to the cylinders. Because there is not enough air to burn all the fuel, the fuel that is not used comes out the exhaust as black smoke. To prevent lugging the engine, use a gear where engine can have "acceleration" (increase in speed) under load.2. Dirty Air Cleaner ... If the air cleaner has a restriction indicator, see if the red piston is in view. If there is no restriction indicator, restriction

Have questions with 101402-7871?

Group cross 101402-7871 ZEXEL

Isuzu

Isuzu

101402-7871

9 400 612 295

8972633951

INJECTION-PUMP ASSEMBLY

4JG1

4JG1