Information injection-pump assembly

BOSCH

9 400 613 968

9400613968

ZEXEL

101402-7410

1014027410

ISUZU

8972133880

8972133880

Rating:

Service parts 101402-7410 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-97030-285-1

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 968

9400613968

ZEXEL

101402-7410

1014027410

ISUZU

8972133880

8972133880

Zexel num

Bosch num

Firm num

Name

101402-7410

9 400 613 968

8972133880 ISUZU

INJECTION-PUMP ASSEMBLY

4BG1 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4BG1 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.3

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

87

85.9

88.1

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.3+-0.5

Pump speed

r/min

440

440

440

Average injection quantity

mm3/st.

8

6.6

9.4

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

100

100

110

Fixing the lever

*

Rack limit

*

Test data Ex:

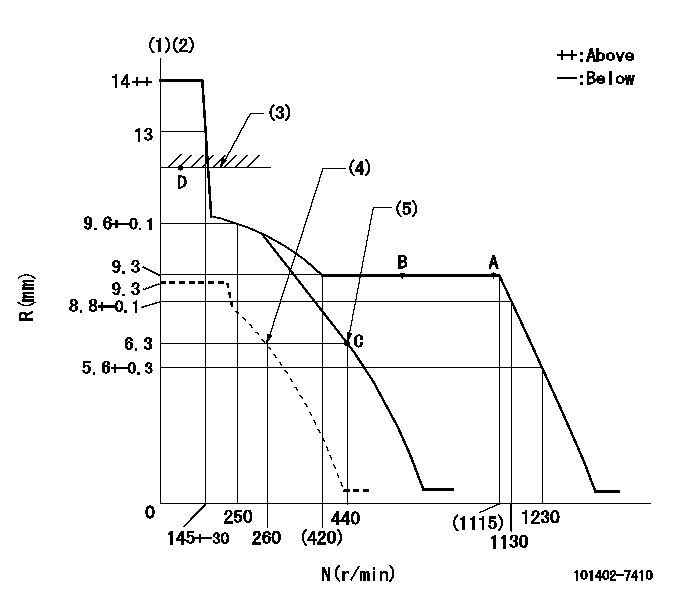

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=13

----------

----------

K=13

----------

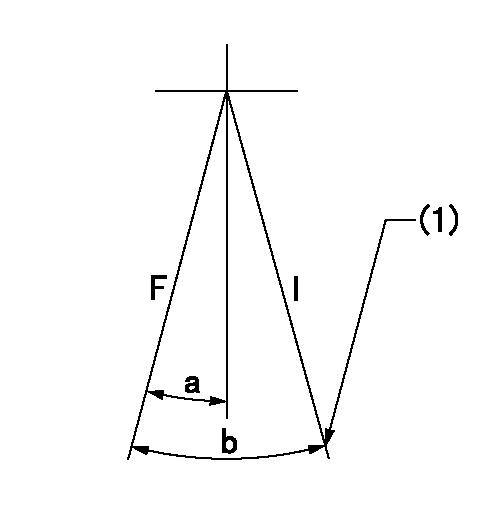

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=12deg+-5deg b=24deg+-5deg

----------

----------

a=12deg+-5deg b=24deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=4.5deg+-5deg b=53deg+-5deg

----------

----------

a=4.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(100deg)

----------

aa=14deg

----------

a=(100deg)

Information:

Lubrication System

The lubrication system consists of the oil pump, cooler, filters, internal passages and the oil pan. The pan can be turned end-for-end to provide either a front or rear sump. The dipstick placement and suction tube length correspond with sump location. A longer suction tube and support is required when the pan is positioned for a rear sump.Oil moves through the screen and suction tube to the inlet passage in the oil pump cover. The oil pump cover bolts to the back of the engine front cover. The inlet passage directs oil to the pump.The oil pump is a six lobe, rotor type. The crankshaft gear drives the outer rotor which rotates in a bearing in the front cover. The inner rotor mounts on a stub shaft in the front cover and is driven by the outer rotor.A bypass valve in the pump cover senses pump outlet pressure. The valve opens at approximately 72 psi (5.1 kg/cm2) and bypasses oil back to the inlet side of the pump.Oil from the pump flows through a passage in the front cover to the cylinder block and on to the oil cooler base. The base mounts on the left side of the block. A valve in the base bypasses oil around the cooler when the oil is cold or the oil cooler restriction is higher than the rest of the system. A 14 to 22 psi (0.89 to 1.55 kg/cm2) pressure differential opens the valve.Oil from the cooler flows to two spin on, throw away filters mounted on the oil cooler base. Each filter contains a bypass valve. If the filters become clogged, oil is bypassed around them. An 18 to 20 psi (1.27 to 1.41 kg/cm2) pressure differential opens the valves.There are three pressure taps in the oil cooler base. Two taps, located on the outlet side of the cooler and filters, are for the oil pressure gauge and a low pressure alarm. One, located on the bypass spring retainer, provides supply oil for an auxiliary filter.A drilled passage in the block directs oil from the filters to the oil manifold. The oil manifold is in the vee above the camshaft mounting and extends the length of the block. Oil flows from the manifold to the camshaft bearings. There are grooves in the cylinder block bore around the camshaft bearings. The camshaft journals are lubricated from these grooves through a hole in the bearing. The remaining oil flows around the groove and down through a drilled passage to a hole and a groove in the upper half of the main bearings. Oil from the hole and groove lubricates the main bearing journals.Oil flows into the crankshaft through holes in the main bearing journals. Drilled passages connect each main bearing journal with the adjacent connecting rod journals. The piston pins are splash lubricated.The rocker arms receive oil from the oil manifold. Drilled passages in the block align with a passage in each of the cylinder heads. The passage to the

The lubrication system consists of the oil pump, cooler, filters, internal passages and the oil pan. The pan can be turned end-for-end to provide either a front or rear sump. The dipstick placement and suction tube length correspond with sump location. A longer suction tube and support is required when the pan is positioned for a rear sump.Oil moves through the screen and suction tube to the inlet passage in the oil pump cover. The oil pump cover bolts to the back of the engine front cover. The inlet passage directs oil to the pump.The oil pump is a six lobe, rotor type. The crankshaft gear drives the outer rotor which rotates in a bearing in the front cover. The inner rotor mounts on a stub shaft in the front cover and is driven by the outer rotor.A bypass valve in the pump cover senses pump outlet pressure. The valve opens at approximately 72 psi (5.1 kg/cm2) and bypasses oil back to the inlet side of the pump.Oil from the pump flows through a passage in the front cover to the cylinder block and on to the oil cooler base. The base mounts on the left side of the block. A valve in the base bypasses oil around the cooler when the oil is cold or the oil cooler restriction is higher than the rest of the system. A 14 to 22 psi (0.89 to 1.55 kg/cm2) pressure differential opens the valve.Oil from the cooler flows to two spin on, throw away filters mounted on the oil cooler base. Each filter contains a bypass valve. If the filters become clogged, oil is bypassed around them. An 18 to 20 psi (1.27 to 1.41 kg/cm2) pressure differential opens the valves.There are three pressure taps in the oil cooler base. Two taps, located on the outlet side of the cooler and filters, are for the oil pressure gauge and a low pressure alarm. One, located on the bypass spring retainer, provides supply oil for an auxiliary filter.A drilled passage in the block directs oil from the filters to the oil manifold. The oil manifold is in the vee above the camshaft mounting and extends the length of the block. Oil flows from the manifold to the camshaft bearings. There are grooves in the cylinder block bore around the camshaft bearings. The camshaft journals are lubricated from these grooves through a hole in the bearing. The remaining oil flows around the groove and down through a drilled passage to a hole and a groove in the upper half of the main bearings. Oil from the hole and groove lubricates the main bearing journals.Oil flows into the crankshaft through holes in the main bearing journals. Drilled passages connect each main bearing journal with the adjacent connecting rod journals. The piston pins are splash lubricated.The rocker arms receive oil from the oil manifold. Drilled passages in the block align with a passage in each of the cylinder heads. The passage to the

Have questions with 101402-7410?

Group cross 101402-7410 ZEXEL

Isuzu

101402-7410

9 400 613 968

8972133880

INJECTION-PUMP ASSEMBLY

4BG1

4BG1