Information injection-pump assembly

BOSCH

9 400 619 833

9400619833

ZEXEL

101402-7360

1014027360

ISUZU

8972063870

8972063870

Rating:

Service parts 101402-7360 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

22.1

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 619 833

9400619833

ZEXEL

101402-7360

1014027360

ISUZU

8972063870

8972063870

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.6

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

104

102.4

105.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

15

13.7

16.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

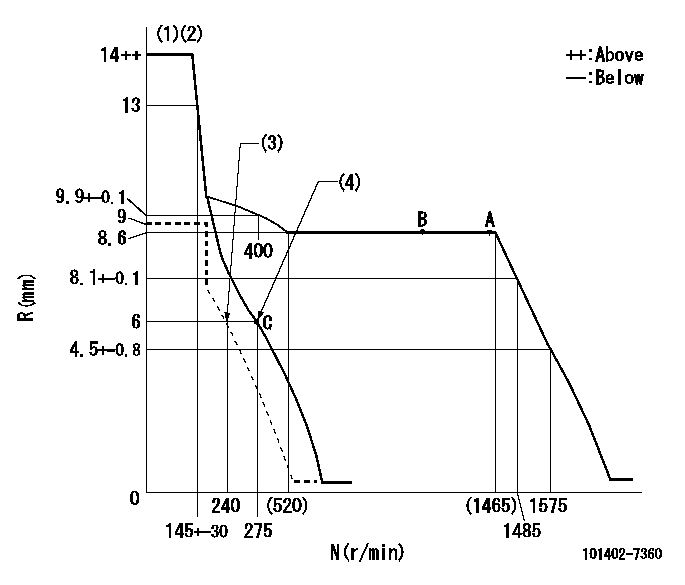

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Set idle sub-spring

(4)Main spring setting

----------

K=14

----------

----------

K=14

----------

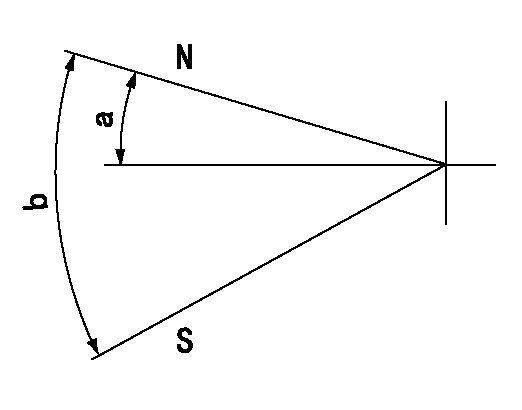

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(15deg)+-5deg b=(28deg)+-5deg

----------

----------

a=(15deg)+-5deg b=(28deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

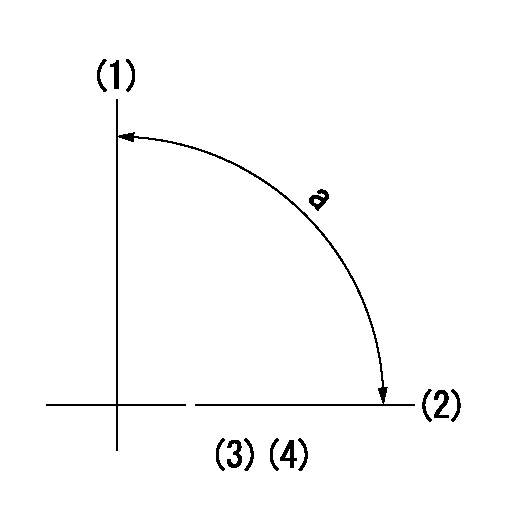

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=20deg

----------

a=(90deg)

----------

aa=20deg

----------

a=(90deg)

Information:

Cooling system components identified are: 1-Fan mounting and drive. 2-Water temperature regulator and housing. 3-Water pump.Water Temperature Regulator

1-Seal. Install seal with lip toward top of cover. 2-Washer.Fan Drive

5F7465 Pullertwo 3/8" NC bolts4 in. (101,6 mm) longand flat washers.

Tools required to remove pulley (1): 5F7465 Puller, two 3/8" NC bolts, 4 in. (101,6 mm) long, and flat washers. Refer to the GENERAL INSTRUCTIONS.Water Pump Disassembly And Assembly

Refer to SERVICE GUIDE for Preliminary Information.8B7548 Push Puller8H663 Bearing Pulling Attachment8B7560 Step Plate8H684 Ratchet Box Wrench1/2" NC Forcing Screw. 1 Install seal assembly in the following manner: a. Wet the outside diameter of the rubber cup-ceramic ring assembly, and the pump housing seal bore, with water. Using hand pressure only, install the rubber seat and ceramic seat squarely in the pump housing bore.b. Wet the inside diameter of the rubber bellows-carbon washer assembly and the water pump shaft with water. Using hand pressure only, install the rubber bellows-carbon washer assembly on the water pump shaft until carbon washer contacts the ceramic ring.c. Install the spring, then install the impeller.2, 4, 5 Remove bearings and gear using an 8B7548 Push Puller, 8H663 Bearing Pulling Attachment, 8B7560 Step Plate, 8H684 Ratchet Box Wrench. Refer to the GENERAL INSTRUCTIONS. Heat bearings and gear to 300° F. (149° C.) before installing on water pump shaft. Do not install shaft in pump housing until gear and bearings have cooled to room temperature.3 Use a 1/2" NC forcing screw to remove impeller. Install the impeller by pressing it onto the water pump shaft until it bottoms on the pump shaft shoulder.